5154 Aluminum Alloy is a high-performance aluminum-magnesium alloy within the 5000 series, renowned for its excellent corrosion resistance, good weldability, and moderate strength. It is widely utilized in industries such as marine, aerospace, and pressure vessels, making it particularly well-suited for use in harsh environments, where it delivers outstanding performance. 5154 aluminum can achieve higher strength through cold working and exhibits excellent machinability during welding and forming, making it an ideal choice for various industrial applications.

Click to view the 5154 Aluminum Bar Product Guide

Mastar supplies various bar manufacturing processes, including extruded bars, cold-worked bars, and forged bars, with specific specifications as follows:

- 5154 extrusion aluminum bar

- Temper: O,H111,H112

- DIA: 0.4"-16"(10-420mm)

- Spec: EN 755,ASTM B221

- 5154 cold finished aluminum bar

- Temper: O,H111,H112,H14,H24,H34,H18

- DIA: 0.125"-8"(3-200mm)

- Spec: EN 754,ASTM B211

- Cold heading of 5154 aluminum wire rod

- DIA: 0.04"-0.6"(1-15mm)

- Spec: EN 754,ASTM B211

- 5154 aluminum forged bar

- DIA: 7.8"-40"(200-1000mm)

- Spec: ASTM B247,AMS-QQ-A-367

Popular products of 5154 aluminum bar

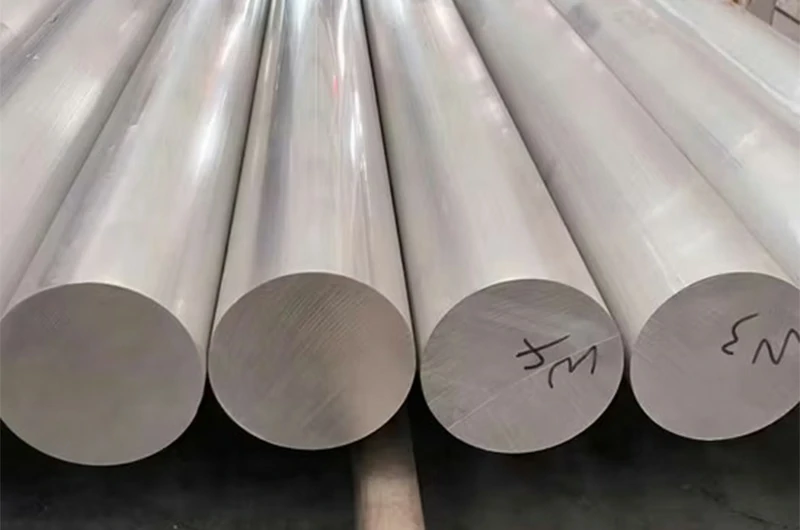

5154 aluminum round bar

5154 aluminum round bar- DIA: 0.4"-16"(10-420mm)

- The 5154 aluminum alloy round bar is widely used in industrial manufacturing due to its excellent corrosion resistance and strength. This product is easy to machine and form, making it suitable for the production of various mechanical and structural components. Its uniform diameter and smooth surface ensure outstanding performance during machining.

5154 aluminum square bar

5154 aluminum square bar- Side Length: 0.2"-8"(5-200mm)

- The 5154 aluminum alloy square bar offers good weldability and formability, making it suitable for structural and frame applications. Its robust characteristics ensure stability under high-load conditions.

5154 aluminum rectangular/flat bar

5154 aluminum rectangular/flat bar- Thickness: 0.08"-8"(2-200mm)

- The 5154 aluminum alloy rectangular/flat bar is widely used in the construction and transportation industries due to its excellent strength and lightweight properties. Its flat surface and precise dimensions ensure outstanding performance during welding and assembly.

5154 aluminum hexagonal bar

5154 aluminum hexagonal bar- Distance Between Flats: 0.2"-8"(5-200mm)

- The 5154 aluminum alloy hexagonal bar features a unique hexagonal shape, making it convenient for use in space-restricted environments. Its strength and corrosion resistance make it an ideal choice for mechanical parts and fasteners.

5154 Large diameter aluminum bar

5154 Large diameter aluminum bar- DIA: 4.8"-53"(124-1350mm)

- The 5154 large diameter aluminum bar provides exceptional strength and rigidity, suitable for high-load applications. Its larger diameter is ideal for manufacturing heavy components and machinery. The excellent corrosion resistance and machinability of the large diameter aluminum bar make it a favored choice in various industrial fields.

5154 aluminum wire rod

5154 aluminum wire rod- The 5154 alloy combines its strength, outstanding formability, and corrosion resistance, making it increasingly popular in cold heading applications, especially for solid, semi-tubular, and tubular rivets.

In addition to 5154 aluminum bars, Mastar also supplies a wide range of aluminum bar alloys in various shapes such as round bars, square bars, flat bars, and hex bars. If you are looking for alternatives with similar machinability or mechanical strength, feel free to explore our whole aluminum bar product pages or contact us for assistance.Quick Quote

Types of 5154 Aluminum Bar

5154 O/H111 Aluminum Extruded bar

5154 O/H111 Aluminum Extruded barEN 755,ASTM B221,EN 754, ASTM B211

5154 H14/H24/H34 Aluminum Cold Fished bar

5154 H14/H24/H34 Aluminum Cold Fished barEN 754, ASTM B211

5154 H18/H28/H38 Aluminum Cold Fished bar

5154 H18/H28/H38 Aluminum Cold Fished barEN 754, ASTM B211

5154 H32/H34/H36 Aluminum Cold Fished bar

5154 H32/H34/H36 Aluminum Cold Fished barEN 754, ASTM B211

As a high-quality aluminum bar supplier, what can we offer you?

- Premium Quality Products: Using high-quality aluminum billets, we employ precise alloying and heat treatment processes to optimize strength and ductility, ensuring uniform cooling and annealing for superior tensile strength and performance.

- Excellent Macro-Structure Control: Produced through reverse extrusion, we manage cooling rates and homogenization processes to keep grain rings within ≤0.5mm, reducing defects and enhancing material consistency and microstructure uniformity.

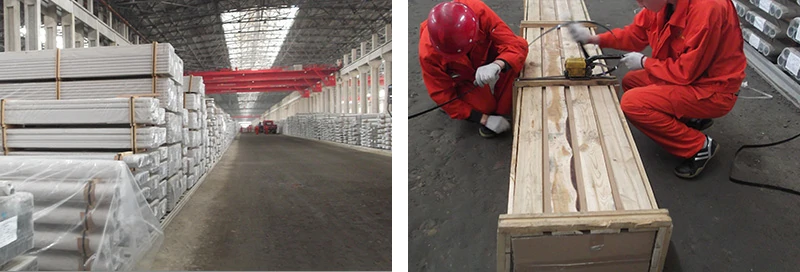

- On-Time Delivery: With over 10,000 tons of inventory, standard sizes are ready to ship. Our advanced equipment and skilled team ensure short lead times and convenient logistics for on-time delivery.

- Competitive Pricing: Supporting retail and bulk purchases, we provide discounts and rebate programs for bulk buyers. Pricing is transparent, ensuring a cost advantage for aluminum bars of equivalent quality.

- Comprehensive Quality Testing: We conduct multiple inspection steps, including tensile strength, elongation, ultrasonic testing, and metallographic analysis to meet AMS, EN, NADCAP certification standards, ensuring each bar meets the highest quality benchmarks.

- Dedicated Customer Service: We offer full-service support, with experienced technical teams providing expert consultation and guidance. Our service system ensures excellent post-purchase experience and customer satisfaction.

Features of 5154 Aluminum Bar

- Excellent Strength and Corrosion Resistance: The 5154 aluminum bar stands out for its structural strength while also providing good corrosion resistance.

- Good Machinability: It is easy to machine and can be formed through processes like cold heading and welding, meeting various manufacturing needs.

- Strong Adaptability: The 5154 aluminum bar performs exceptionally well in industries such as aerospace and automotive, making it suitable for high-strength connectors and structural components.

- Outstanding Heat Treatment Performance: The 5154 aluminum bar can enhance its mechanical properties through heat treatment, maintaining stability and durability under high-load conditions.

In addition to 5154 aluminum bar, MASTAR also provides a range of related aluminum bar alloys with similar strength, corrosion resistance, or forming performance. Depending on specific application requirements or project scope, customers may consider the options below to find the most suitable material — whether for single-part selection or full-system aluminum sourcing.

Best Collaboration Fields for 5154 Aluminum Bar

- Aerospace: Due to its excellent strength and lightweight characteristics, the 5154 aluminum bar is commonly used to manufacture aircraft structural components and other aerospace parts.

- Automotive Industry: In automotive manufacturing, this aluminum alloy is widely used in body structures, chassis components, and connectors to improve vehicle safety and fuel efficiency.

- Marine Engineering: The 5154 aluminum bar is highly corrosion-resistant, making it ideal for use in ships, marine platforms, and other underwater structures.

- Construction Industry: This aluminum bar is often used in building decorations, frame structures, and support systems, providing both strength and aesthetic appeal.

- Power and Transmission: In the power industry, the 5154 aluminum bar is utilized to manufacture utility poles, conductive components, and other power transmission equipment due to its good conductivity and oxidation resistance.

5154 aluminum bar procurement guide

1. Comprehensive documentation

Msatar can provide detailed quality testing reports, including raw material certificates, laboratory test reports, fumigation reports, specification guides, commercial invoices, and guarantees, ensuring the quality transparency and traceability of each batch of products.

2. Fine export packaging

In international shipping, the quality of packaging directly affects whether goods can rust, corrode, scratch, deform, or suffer other damages during transport. Therefore, high-quality packaging materials are crucial. Msatar has years of export packaging experience, providing safe and reliable packaging solutions for thousands of businesses. By using fumigated wooden boxes, wooden pallets, and other high-quality packaging materials, our packaging damage rate is only one-third of the industry average.

3. Professional loading solutions

Our experienced order-following team can provide flexible and diverse loading solutions, including options for 20/40-foot containers or bulk ships. Regardless of your cargo specifications and shapes, we can customize a refined loading plan that saves an average of 15% container space, effectively reducing your logistics costs.

Product Guide of 5154 aluminum bar

Standard Specifications of 5154 aluminum bar

- EN 573-3 - 2009 Aluminium and aluminium alloys. Chemical composition and form of wrought products. Chemical composition and form of products

- EN 755 - 2008 Aluminium and aluminium alloys. Extruded rod/bar, tube and profiles

- EN 754 - Aluminum and Aluminum Alloys - Cold Drawn Rod/Bar, Tube and Profiles

- ASTM B221 - Aluminum and Aluminum-Alloy Extruded Bars, Rods, Wire, Profiles, and Tubes

- ASTM B211 - Aluminum and Aluminum-Alloy Rolled or Cold Finished Bar, Rod

Chemical composition of 5154 aluminum bar(EN 573-2)

| Element | 5154A | 5154B |

| Si | 0.50 | 0.35 |

| Fe | 0.50 | 0.45 |

| Cu | 0.10 | 0.05 |

| Mn | 0.5 | 0.15-0.45 |

| Mg | 3.1-3.9 | 3.2-3.8 |

| Cr | 0.25 | 0.10 |

| Ni | - | 0.01 |

| Zn | 0.20 | 0.15 |

| Ti | 0.20 | 0.15 |

| Remarks | Mn+Cr 40.10-0.50 | - |

| Others (Each) | 0.05 | 0.05 |

| Others (Total) | 0.15 | 0.15 |

| Al | Rem | Rem |

Physical properties of 5154 aluminum bar

| Properties | Value |

| Density | 2.66 g/cm³ |

| Melting point | 593 - 643 °C |

| Thermal conductivity | 125 W/m·K |

| Coefficient of thermal expansion | 23.9 µm/m·°C |

| Electrical conductivity | 32 % IACS |

Mechanical properties of 5154 extrusion aluminum bar(EN 755-2)

| Properties | O | H111 | H112 |

| Tensile strength Rm/Mpa | 200-275 | 200-275 | 200 |

| Yield strength Rp0.2/Mpa | 85 | 85 | 85 |

| Elongation | 16-18% | 16-18% | 14-16% |

| Hardness | 55 | 55 | 55 |

Mechanical properties of 5454 Cold Finish aluminum bar(EN 754-2)

| Properties | O/H111 | H14/H24/H34 | H18/H28/H38 |

| Tensile strength Rm/Mpa | 200-260 | 260-320 | 310 |

| Yield strength Rp0.2/Mpa | 85 | 200 | 240 |

| Elongation | 14-16% | 4-5% | 2-3% |

| Hardness | 55 | 75 | 80 |

Why is 5154 Aluminum Bar Ideal for Marine Applications?

Excellent Corrosion Resistance: The 5154 aluminum alloy, which contains magnesium, enhances its oxidation and corrosion resistance, particularly effective against seawater erosion.

Lightweight Properties: Compared to steel, aluminum alloys have a lower density, helping to reduce the overall weight of marine structures and lowering the support requirements, thus improving the performance and efficiency of ships and marine platforms.

Good Weldability: The 5154 aluminum bar is easy to weld, making it suitable for manufacturing and repairing complex structures, ensuring stability and safety in marine engineering.

Strength and Toughness: This aluminum alloy provides good strength while maintaining some toughness, allowing it to withstand impacts and pressures in marine environments, making it suitable for load-bearing components.

Low Maintenance Requirements: Due to its corrosion resistance and strength, marine facilities using the 5154 aluminum bar require less maintenance, reducing long-term operating costs.

In addition to 5154, several other aluminum bar alloys are also widely used in marine applications due to their excellent corrosion resistance, strength, and weldability. Depending on the structural requirements or environmental conditions, the following grades may also be worth considering.

5154 vs 5454

Composition and Alloy Properties

5154 aluminum alloy, primarily composed of magnesium (approximately 4-5%), is known for its good corrosion resistance, weldability, and formability, making it suitable for lightweight and corrosion-resistant applications.

5454 aluminum alloy, also containing a high level of magnesium (about 4-5%), has a slightly higher magnesium content than 5154, resulting in better strength and corrosion resistance, particularly in harsh environments.

Mechanical Properties

5154: Provides good tensile strength and ductility, suitable for medium-load structural components.

5454: Due to its higher magnesium content, it typically offers greater strength, making it suitable for applications that endure larger loads.

Welding Performance

5154: Exhibits good welding performance, suitable for various welding methods.

5454: Also shows excellent welding performance, suitable for the manufacturing of ships and marine structures.

Application Fields

5154: Commonly used in ships, transportation, and storage equipment.

5454: Due to its superior corrosion and impact resistance, it is typically used in marine environments, pressure vessels, and storage tanks that require higher specifications.

Cost

5154: Relatively low cost, making it suitable for budget-limited projects.

5454: May be slightly more expensive, but its superior performance and durability yield better long-term usage results.