T-slot frame profiles combine to build operating platform, racks, barriers, workstations and other structures without the need for welding. As facility needs change, the structure can be expanded or reconfigured.

These extruded aluminum profiles feature recessed T-slots to accommodate compatible connectors and fasteners. Connectors connect profiles to create a structural frame. Fasteners allow hinges, panels, handles and other components to be attached to profiles to customize the structure.

T-slot aluminum profile specifications

Alloy: 6061-T6, 6063-T5 , 6063-T5 , 6005-T5 , 6560-T6 , 6105-T5

Processing: anodized, silver, black, cut to length

Product type: t-slot profiles, guide rails, accessories, overall frame

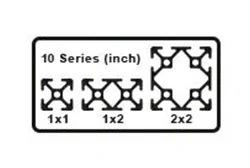

Fractional 10 series (based on 1*1 '' profile) | 10*10 t-slot 10*20 t-slot |

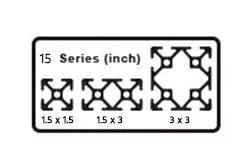

Fractional 15 series (based on 1.5*1.5 '' profile) | 15*15 t-slot 15*30 t-slot |

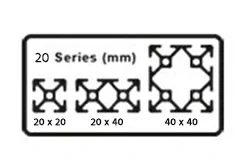

Metric 20 series (based on 20*20mm profile) | 20*20 t-slot 20*40 t-slot 20*80 t-slot |

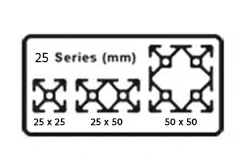

Metric 25 series (based on 25*25mm profile) | 25*25 t-slot 25*50 t-slot 50*50 t-slot |

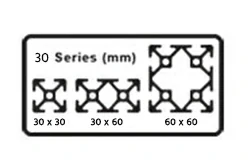

Metric 30 series (based on 30*30mm profile) | 30*30 t-slot 30*60 t-slot 60*60 t-slot |

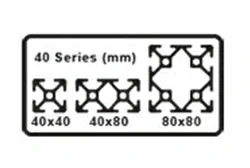

Metric 40 series (based on 40*40m profile) | 40*40 t-slot 40*80 t-slot 80*80 t-slot |

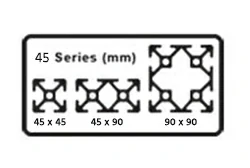

Metric 45 series (based on 45*45 profile) | 45*45 t-slot 45*90 t-slot 90*90 t-slot |

T-slot hot selling product types

Heavy profile t-slot |  Standard profile t-slot |  Light profile t-slot |

Silver t-slot |  Black anodized t-slot |  Yellow anodized t-slot |

Single with 4 Full-Perimeter Slots |  Single with 1 Side Slot |  Single with 2 Corner Side Slots |

Single with 2 Corner Side Slots |  Single with 3 Adjacent Side Slots |  Half-Single with 1 Single- Side Slot |

Angled Single with 2 Corner Side Slots |  Radius Single with 2 Corner Side Slots |  Quarter round profile |

Double with 2 Single-Side Slots |  Double with 2 Opposite- Side Slots |  Double with 3 Corner-Side Slots |

Double with 4 Adjacent-Side Slots |  Half-Double with 2 Single- Side Slots |  Triple with 8 Full-Perimeter Slots |

Quad with 8 Full-Perimeter Slots |  Dual-Quad with 12 Full- Perimeter Slots |  Double with 6 Full-Perimeter Slots |

Extruded aluminum t-slot accessories

The MASTAR product range not only includes diverse T-slot aluminum materials, but also covers a wide range of T-slot installation connection accessories. Whether you need accessories for connecting, fixing or supporting, we have a variety of options to meet your various T-channel structural assembly needs. For detailed explanations and use cases of brackets, plates, and joining methods, you can explore our guide to aluminum profile connections. Quick Quote

| T slot aluminum connectors Aluminous tee extrusion Angle Brackets Joining Plates Transportation Connectors Slider Guide Rails | Aluminun extrusion t-slot fastener Bolts and Nuts Leveling Feet End Caps Reinforcement Brackets Reinforcement Plates Frame to floor |

| Accessories for adjustment and positioning Adjustable Feet Adjusting Rods Positioning Pins Positioning Blocks T slot aluminum bearing | Accessories for operation and adjustment Handles Hand wheels Castor wheels Adjusting rods Dumpling chain (hinge) |

| Accessories for protection and decoration T- slot reducer End cap Panel strips T-slot cover Filler Strips Decorative Trims | Accessories for special functions Cylinder Brackets Sensor Brackets Pressure Relief Vents Pipe Clamps |

Integrated solutions with T-slot framing system

MASTAR provides a wide range of T-slot profiles and accessories, and its services cover multiple industries. Whether you are in manufacturing, machinery, automation, engineering construction or other industries, we can meet your needs for T- slot structures. Quick Quote

T slot for table frame

T slot for table frame- Larger size T-channel profiles are usually selected, such as 40 series or larger, to ensure that the table frame has sufficient stability and load-bearing capacity.

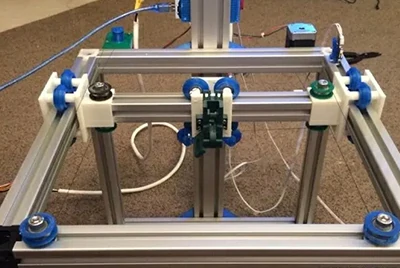

Extruded aluminum t slot for 3d printer printing

Extruded aluminum t slot for 3d printer printing- Smaller size T-slot profiles, such as Series 20 or Series 30, are often used in printer frames because they are lightweight and easy to assemble.

T slot for window frame system

T slot for window frame system- Medium-sized T-channel profiles, such as the 30 series, are usually selected to balance structural stability and appearance aesthetics.

T-slot for workstation, test station, workbench

T-slot for workstation, test station, workbench- Choose T-channel profiles with larger sizes , such as 40 series or larger, to ensure that the workbench has sufficient strength and stability.

T-slot for office and workshop furniture

T-slot for office and workshop furniture- Choose the appropriate size T-channel profile according to the needs of the specific furniture. Common choices include sizes between 20 series and 40 series.

T-slot aluminum framing for trailers

T-slot aluminum framing for trailers- Larger size T-channel profiles are usually chosen, such as 40 series or larger, to ensure a stable and durable trailer structure.

T slot for roof rack

T slot for roof rack- Generally, T-channel profiles of moderate size, such as 30 series, are selected to balance lightweight and load-bearing capacity.

T-slot for ladders

T-slot for ladders- Usually, larger size T-channel profiles, such as 40 series, are used to ensure that the ladder structure is strong and reliable.

T-slot product performance parameter table

Not all extruded profiles are created equal. Two profiles may have the same external dimensions (for example 45 x 45 mm) but have completely different stiffnesses, depending on their cross-sectional area and area moment of inertia.

- The cross-sectional area of a profile refers to the area formed by the material cross-section perpendicular to its length. The cross-sectional area determines the quality and load-bearing capacity of the profile. A larger cross-sectional area usually means greater mass and higher load-bearing capacity.

- The area moment of inertia describes the resistance of a material section to bending and torsion. The larger the area moment of inertia means the profile is more resistant to bending and torsion and has higher rigidity.

In engineering design, engineers need to comprehensively consider these indicators to select the profile that is most suitable for specific application scenarios. The following table takes the 45*45 profile as an example to introduce the key parameters of t-slot of different cross-sections. For other specifications, size and performance parameters, please contact for consultation. Quick Quote

|  |  |  |  | |

| Profile Dimensions (mm) | 45 x 45 | 45 x 45 | 45 x 45 | 45 x 45 | 45 x 45 |

| Material (aluminum) | 6063-T5 | 6063-T5 | 6005-T5 | 6560-T6 | 6105-T5 |

| Profile area (mm2) | 571 | 737 | 761 | 563 | 757 |

| Area moment of inertia (mm4) | 109,635 | 141,720 | 162,325 | 107,780 | 139,310 |

| Torsional constant (mm4) | 19,836 | 39,719 | 31,851 | 19,394 | 31,042 |

| Weight per meter (kg) | 1.55 | 2.03 | 2.06 | 1.63 | 2.05 |

| (Area moment of inertia) / (Surface Area) (mm2) | 192 | 192 | 213 | 191 | 184 |

| Max deflection (500mm cantilever) at 1500 N force (mm) | 8.25 | 6.3 | 5.58 | 8.28 | 6.5 |

| Stress (500mm cantilever) at 1500 N force (MPa) | 153.48 | 117.11 | 103.96 | 156.57 | 121.05 |

| Torsional displacement (1m length) at 50 Nm torque (degrees) | 5.55 | 2.77 | 3.46 | 5.68 | 3.55 |

These structural parameters—such as cross-sectional area and moment of inertia—are critical for evaluating load-bearing capacity and rigidity in real-world applications. To deepen your understanding and make the right selection for your project, feel free to explore the resources below or contact us for tailored consultation. Quick Quote

T-slot vs V-slot Profile Comparison – Understand the differences in slot structures and which is right for your project

Extrusion Process – Learn how T-slot profiles are made from raw aluminum billets

Select MASTAR extrusion T-slot profile

- Fast delivery: We have extensive inventory to ensure fast delivery of any standard aluminum profile, saving time for the smooth progress of your project.

- High-quality products: The quality of our products meets standards and certifications, with light weight, high strength and accurate precision, making frame connection more convenient, strong and tight .

- Customized profiles: In addition to standard aluminum profiles, MASTAR can also provide customized aluminum profiles according to customer requirements for size and surface finish. You only need to indicate the alloy, length, quantity, surface finish, end use and other special requirements to us.

- Cut to size: We offer a precision cutting service to ensure your aluminum profile is the length you require with an accuracy of +/- 0.2mm. This level of precision ensures your project requirements are seamlessly met.

- Angle Cuts: Our skilled team can perform diagonal cuts up to +/- 60 degrees, giving you the flexibility to create unique shapes and configurations for your project.

- After-sales support: We can provide fast after-sales support to ensure that you receive timely help and support when using our products.

FAQ for purchasing MASTAR aluminum t-slot

Q1: What's the difference between T-slot and V-slot aluminum profiles?

A: T-slot profiles have a rectangular groove that allows flexible mounting of brackets, fasteners, and panels, making them ideal for modular structures. V-slot profiles, on the other hand, have angled grooves that double as linear guide rails for wheels. Read our t-slot and v-slot comparison to decide which is best for your application.

Q2: How do I connect different T-slot profiles together?

A: T-slot profiles are connected using accessories like angle brackets, joining plates, sliders, and fasteners. The choice depends on the strength required, adjustability, and connection direction. You can refer to our guide on aluminum profile joining methods for more detailed options.

Q3: What surface treatments are available for T-slot aluminum profiles?

A: The most common surface treatments include anodizing (silver, black, yellow), powder coating, and sandblasting. Anodizing enhances corrosion resistance and aesthetics. See more about surface treatment options.

Q4: How do I choose the right T-slot profile for strength and load capacity?

A: Key factors include cross-sectional area, area moment of inertia, and the alloy used (e.g., 6063-T5, 6005-T5). Larger profiles (e.g., 45×90) and higher inertia values provide better stiffness. Refer to our parameter table above or contact us for application-specific advice.

Q5: What industries commonly use T-slot aluminum framing systems?

A: T-slot frames are widely used in manufacturing, automation, robotics, office furniture, trailers, and 3D printing. You can explore examples in our aluminum profile use cases.

Q6: What's the difference between direct and indirect extrusion in profile production?

A: Direct extrusion forces the billet through a stationary die, while in indirect extrusion the die moves toward the billet. Each method affects surface finish and profile accuracy. Learn more in our article on extrusion methods.

Q7: Can I customize the length or shape of the T-slot profile I need?

A: Yes. MASTAR provides custom cut-to-length profiles (accuracy ±0.2 mm), angle cuts (up to ±60°), and special surface finishes. Just specify your alloy, size, and functional needs when placing your order.

Q8: What series of T-slot should I choose for furniture, machines, or structures?

A:

20/30 series: Lightweight structures like 3D printer frames or display stands

40/45 series: Heavy-duty workstations, equipment racks, trailers, and automation setups

Explore our application-based selection guide or contact us for recommendations.Quick Quote