5456 aluminum bar is a high-strength forged aluminum-magnesium alloy, known for its excellent corrosion resistance, weldability, and versatility. It maintains stable performance in extreme temperature conditions, ranging from low temperatures to 200°C.

5456 aluminum bar is primarily used in industries such as aerospace, commercial, oil and gas, nuclear energy, marine, and defense. It is ideal for applications that require high strength and durability in harsh environments, including defense, marine hull structures, pressure vessels, and welded structures. Thanks to its excellent mechanical properties, 5456 aluminum bar is an ideal choice for manufacturing critical components and structures.

Click to view the 5456 Aluminum Bar product guide

Mastar offers various aluminum bar products, including extruded bars and cast bar billets, with a wide range of specifications and sizes available:

- 5456 extrusion aluminum bar

- Temper: O,H111, H112

- DIA: 0.4"-16"(10-420mm)

- Spec: EN 755,EN 573

- 5456 aluminum cast billets bar

- Temper: F

- DIA: 4.8"-53"(124-1350mm)

- Material used for subsequent extrusion production

Popular 5456 Aluminum Bar Products

- 5456 O/H111 extrusion aluminum bar

- 5456 H112 extrusion aluminum bar

- 5456 aluminum round bar

- 5456 aluminum square bar

- 5456 aluminum rectangular/flat bar

- 5456 aluminum hexagonal bar

In addition to 5456 aluminum bars, Mastar also supplies a wide range of aluminum bar alloys in various shapes such as round bars, square bars, flat bars, and hex bars. If you are looking for alternatives with similar machinability or mechanical strength, feel free to explore our whole aluminum bar product pages or contact us for assistance.Quick Quote

As a high-quality aluminum bar supplier, what can we offer you?

- Premium Quality Products: Using high-quality aluminum billets, we employ precise alloying and heat treatment processes to optimize strength and ductility, ensuring uniform cooling and annealing for superior tensile strength and performance.

- Excellent Macro-Structure Control: Produced through reverse extrusion, we manage cooling rates and homogenization processes to keep grain rings within ≤0.5mm, reducing defects and enhancing material consistency and microstructure uniformity.

- On-Time Delivery: With over 10,000 tons of inventory, standard sizes are ready to ship. Our advanced equipment and skilled team ensure short lead times and convenient logistics for on-time delivery.

- Competitive Pricing: Supporting retail and bulk purchases, we provide discounts and rebate programs for bulk buyers. Pricing is transparent, ensuring a cost advantage for aluminum bars of equivalent quality.

- Comprehensive Quality Testing: We conduct multiple inspection steps, including tensile strength, elongation, ultrasonic testing, and metallographic analysis to meet AMS, EN, NADCAP certification standards, ensuring each bar meets the highest quality benchmarks.

- Dedicated Customer Service: We offer full-service support, with experienced technical teams providing expert consultation and guidance. Our service system ensures excellent post-purchase experience and customer satisfaction.

Characteristics of 5456 Aluminum Bar

- Excellent corrosion resistance: Performs outstandingly in atmospheric and marine environments, making it ideal for coastal and offshore applications.

- High strength: Provides a good balance between tensile strength and yield strength, suitable for demanding structural applications.

- Good weldability: Easy to weld, ensuring high-strength joints and efficient manufacturing processes.

- Excellent formability: Easy to shape and machine, enabling complex design options.

- Good machinability: Suitable for precise manufacturing of detailed parts, easy to cut and shape.

Best applications of 5456 aluminum bar

- Shipbuilding: Used in hull structures, decks, and marine platforms, offering superior corrosion resistance and strength.

- Oil and gas: Used in pipelines, offshore platforms, and drilling equipment, capable of withstanding high pressure and corrosive environments.

- Pressure vessels: Ideal for manufacturing high-pressure gas cylinders and liquid storage tanks, ensuring structural integrity.

- Defense industry: Used in armored vehicles, missile components, and military aircraft, providing strength and reliability.

- Construction and transportation: Widely used in bridges, buildings, and high-performance structures due to its corrosion resistance and strength.

Product Guide of 5456 aluminum bar

Standard Specifications of 5456 aluminum bar

- EN 573-3 - 2009 Aluminium and aluminium alloys. Chemical composition and form of wrought products. Chemical composition and form of products

- ASTM B210 - Standard Specification for Aluminum and Aluminum-Alloy Drawn Seamless Tubes

- ASTM B241 - Standard Specification for Aluminum and Aluminum-Alloy Seamless Pipe and Seamless Extruded Tube

Chemical composition of 5456 aluminum bar(EN 573-2)

| Element | 5456A | 5456B |

| Si | 0.25 | 0.25 |

| Fe | 0.40 | 0.40 |

| Cu | 0.05 | 0.05 |

| Mn | 0.7-1.1 | 0.7-1.1 |

| Mg | 4.5-5.2 | 4.5-5.2 |

| Cr | 0.05-0.25 | 0.05-0.25 |

| Ni | - | - |

| Zn | 0.25 | 0.25 |

| Ti | 0.15 | 0.15 |

| Remarks | 4 | 18 |

| Others (Each) | 0.05 | 0.05 |

| Others (Total) | 0.15 | 0.15 |

| Al | Rem | Rem |

Physical properties of 5456 aluminum bar

| Properties | Value |

| Density | 2.66 g/cm³ |

| Melting point | 568.3 - 638 °C |

| Thermal conductivity | 116 W/m·K |

| Coefficient of thermal expansion | 23.9 µm/m·°C |

| Electrical conductivity | 29 % IACS |

Mechanical properties of 5456 extrusion aluminum bar(ASTM B221)

| Properties | O | H111 | H112 |

| Tensile strength Rm/ksi | 41-53 | 42 | 41 |

| Yield strength Rp0.2/ksi | 19 | 26 | 19 |

| Elongation | 14% | 12% | 12% |

How is the Machinability of 5456 Aluminum Alloy?

5456 aluminum alloy offers excellent machinability, making it easy to cut and form using standard tools, which is ideal for manufacturing complex parts. It can be shaped through processes such as rolling, extrusion, and welding, meeting a wide range of design requirements. It also has good cold-working capabilities, which allow for strength improvements, though care should be taken to avoid excessive cold working to prevent stress corrosion cracking. Hot working at 218°C (425°F) can further enhance the performance of 5456 aluminum alloy.

How is the Welding Performance of 5456 Aluminum Alloy?

5456 aluminum alloy has excellent weldability, making it suitable for both MIG (Metal Inert Gas) and TIG (Tungsten Inert Gas) welding methods. It can form high-strength, corrosion-resistant weld joints, ensuring reliability even in harsh environments.

Additionally, the excellent welding characteristics of 5456 aluminum alloy result in minimal performance variation in the heat-affected zone during welding, which helps maintain the overall strength and toughness of the material. This makes it highly effective for meeting the high strength and durability requirements in shipbuilding and other structural applications requiring welding.

Why is 5456 Aluminum Bar Suitable for the Defense Industry?

1. High Strength and Impact Resistance: The tensile strength of 5456 aluminum alloy ranges from 320-340 MPa, ensuring excellent performance under external impacts and pressure. This strength makes it an ideal material for manufacturing military armor, missile components, armored vehicles, and military aircraft, effectively resisting enemy attacks and ensuring the safety of equipment and personnel.

2. MIL Certification: As an aluminum alloy that meets MIL (military) certification, 5456 aluminum bar complies with stringent military standards, ensuring its reliability under high-strength, high-pressure, and harsh conditions. The MIL certification guarantees that the material's quality and performance meet military needs, offering durability and strength to withstand the tough conditions of modern warfare.

| 5456 Aluminum Extruded Armor Standard: MIL-DTL-46083 5456 aluminum bar offers high impact resistance, penetration resistance, and corrosion resistance. It is used as extruded billets for armored vehicles, aircraft, and other equipment that requires lightweight protection. | 5456 Aluminum Forged Armor Standard: MIL-DTL-45225 5456 aluminum bar boasts high strength, fatigue resistance, and excellent impact and corrosion resistance. It is used as forged billets for manufacturing military armor and critical protective components. |

3. Corrosion Resistance: 5456 aluminum alloy has exceptional corrosion resistance, especially in marine environments. This feature is vital for the defense industry, ensuring equipment remains reliable and functional in seawater, humid, or corrosive environments. Applications like naval ships, military aircraft, and offshore platforms demand this feature.

4. Stress Corrosion Cracking Resistance: While 5456 aluminum alloy can be susceptible to stress corrosion cracking (SCC) under certain high-temperature conditions, with appropriate design and material treatment, particularly in high-strength welded structures, it still offers excellent durability and reliability. In the defense sector, proper design and construction can minimize these issues.

5. Excellent Weldability: 5456 aluminum bar is highly suitable for high-strength welding, producing strong weld joints to ensure equipment integrity under impact, vibration, or extreme loads. This makes the alloy highly reliable in military equipment manufacturing, especially in structurally demanding applications.

In addition to 5456, Mastar supplies other aluminum bar alloys that are widely used in the defense and aerospace sectors. These materials offer exceptional strength, fatigue resistance, and performance under extreme conditions — ideal for structural, ballistic, or precision components.

What Are the Advantages of 5456 Aluminum Alloy as a Typical Marine Alloy?

1. Excellent Corrosion Resistance: 5456 aluminum alloy has a high magnesium content, which gives it outstanding corrosion resistance in saltwater and marine environments. This feature is crucial for the long-term durability and structural integrity of marine components, reducing the need for regular maintenance and protective coatings.

2. High Strength and Rigidity: With a tensile strength typically between 320-340 MPa, 5456 aluminum alloy outperforms 5083 aluminum alloy in terms of strength. This high strength makes it capable of withstanding heavy loads in marine operations, making it ideal for hull structures and other load-bearing components in ships.

3. Good Weldability: 5456 aluminum alloy is easy to weld, ensuring strong and corrosion-resistant weld joints. This is critical for shipbuilding, where welded parts need to maintain their reliability in harsh environments. It ensures that the welded joints in marine structures are durable and resistant to environmental stresses.

4. Lightweight Material: The inherent lightweight properties of aluminum alloys help reduce the overall weight of the ship, improving fuel efficiency and payload capacity. This is becoming increasingly important in modern shipbuilding where lightweight and efficient performance are priorities.

5. Excellent Formability and Machinability: 5456 aluminum alloy can be processed into complex shapes through rolling, extrusion, and other manufacturing methods, making it highly flexible for various marine construction and shipbuilding applications.

6. Shock Resistance: The toughness and uniform grain structure of 5456 aluminum alloy help it resist vibrations and impacts in marine environments, improving the overall safety of the vessel. The high magnesium content enhances ductility and toughness, allowing the material to absorb shock without easily breaking.

As a typical marine-grade alloy, 5456 shares similar performance characteristics with other Al-Mg series aluminum bars. For applications involving hull structures, decks, or offshore equipment, the following materials are also commonly selected for their corrosion resistance and weldability.

5083 vs 5456

Given their performance similarities, 5083 and 5456 aluminum alloys are often compared in marine and structural applications. While this section focuses on 5456, you can also explore our 5083 aluminum bar to evaluate which alloy best fits your specific project requirements in terms of strength, corrosion resistance, and formability.

- Strength: The tensile strength of 5154 is typically around 320-340 MPa, which is slightly higher than 5083 aluminum's 290-320 MPa, making 5154 better for high-strength applications.

- Corrosion Resistance: Both alloys exhibit excellent corrosion resistance, particularly in marine environments. However, 5154's higher magnesium content provides superior corrosion resistance in seawater environments.

- Weldability: Both alloys are easy to weld, but 5456 aluminum alloy outperforms 5154 in terms of post-weld strength and corrosion resistance, which is crucial for critical marine joints.

- Formability: 5083 aluminum alloy is more suitable for casting, while 5154 is better suited for rolling and extrusion, adapting better to complex shape manufacturing.

- Application Areas: 5083 is commonly used in marine vessels, pressure vessels, and marine engineering, while 5456 aluminum alloy is widely used in high-strength welded structures, storage tanks, and other high-load-bearing applications.

5456 aluminum bar procurement guide

1.Comprehensive documentation

Msatar can provide detailed quality testing reports, including raw material certificates, laboratory test reports, fumigation reports, specification guides, commercial invoices, and guarantees, ensuring the quality transparency and traceability of each batch of products.

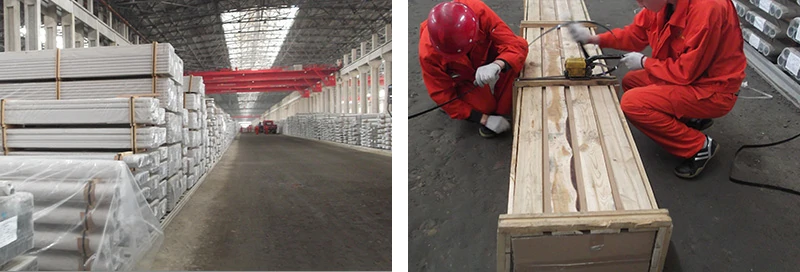

2.Fine export packaging

In international shipping, the quality of packaging directly affects whether goods can rust, corrode, scratch, deform, or suffer other damages during transport. Therefore, high-quality packaging materials are crucial. Msatar has years of export packaging experience, providing safe and reliable packaging solutions for thousands of businesses. By using fumigated wooden boxes, wooden pallets, and other high-quality packaging materials, our packaging damage rate is only one-third of the industry average.

3.Professional loading solutions

Our experienced order-following team can provide flexible and diverse loading solutions, including options for 20/40-foot containers or bulk ships. Regardless of your cargo specifications and shapes, we can customize a refined loading plan that saves an average of 15% container space, effectively reducing your logistics costs.