5056 aluminum alloy is a high-strength, corrosion-resistant aluminum-magnesium alloy widely used in fields requiring excellent corrosion resistance and lightweight properties. It performs particularly well in marine environments, low-temperature conditions, and aerospace industries due to its exceptional resistance to saltwater corrosion and outstanding weldability.

The 5056 aluminum alloy offers good formability and machinability, commonly supplied in cold-finished bars and wire rods for cold heading, suitable for producing bolts, screws, rivets, and other fasteners. Although it cannot be strengthened through heat treatment, its inherent high strength and corrosion resistance allow it to maintain superior performance in various demanding environments.

Click to view the 5056 Aluminum Bar Product Guide

Msatar provides bars in various processes, including cold-finished bars, aluminum wire rods for cold heading, and casting billets, with specific sizes and dimensions as follows:

- 5056 cold Finished aluminum bar

- Temper: O,H32, H34,H36, H38,H112

- DIA: 0.2"-8"(5-200mm)

- Spec: ASTM B211,AMS 4182

- 5056 cold Finished aluminum bar

- Temper: O,H32

- DIA: 0.08"-1"(2-25.4mm)

- Spec: ASTM B316,AMS-QQ-A-430

- 5056 cold Finished aluminum bar

- Temper: F

- DIA: 4.8"-53"(124-1350mm)

- Material used for subsequent extrusion production

Popular Products of 5056 Aluminum Bar

- 5056 O cold finished aluminum bar

- 5056 H32/H34 cold finished aluminum bar

- 5056 H36/H38 cold finished aluminum bar

- 5056 O aluminum wire rod

- 5056 H32 aluminum wire rod

- 5456 aluminum round bar

- 5056 aluminum square bar

- 5056 aluminum rectangular/flat bar

- 5056 aluminum hexagonal bar

In addition to 5056 aluminum bars, Mastar also supplies a wide range of aluminum bar alloys in various shapes such as round bars, square bars, flat bars, and hex bars. If you are looking for alternatives with similar machinability or mechanical strength, feel free to explore our whole aluminum bar product pages or contact us for assistance.Quick Quote

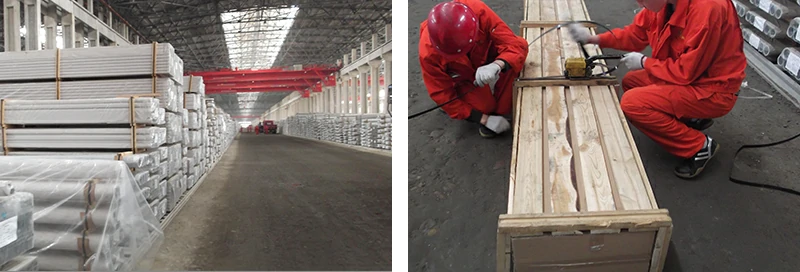

What We Can Offer as a High-Quality Aluminum Bar Supplier

- Premium Products: Using high-quality aluminum billets, we employ precise alloying and heat treatment processes to optimize product strength and ductility, ensuring uniform cooling and annealing. This guarantees high tensile strength and superior performance.

- Excellent Grain Control: Produced through reverse extrusion with controlled cooling and homogenization, the coarse grain ring is kept within ≤0.5mm, minimizing defects and ensuring structural consistency. For customers with higher demands on dimensional accuracy and surface quality, we also provide precision ground aluminum bars suitable for CNC and tight-tolerance applications.

- Timely Delivery: With tens of thousands of tons in inventory, standard sizes can be directly matched to stock, ensuring rapid shipment. Advanced equipment and a professional team shorten delivery time, providing efficient logistics for on-time delivery.

- Competitive Pricing: Supporting both retail and bulk purchasing for metal distributors, we offer discounts and rebate policies for B2B clients. Pricing is transparent, and we ensure a price advantage for bars of the same quality.

- Comprehensive Quality Inspection: We strictly implement multiple inspection procedures, including tensile strength, elongation performance, ultrasonic testing, and metallographic testing to ensure that aluminum bars meet AMS, EN, NADCAP, and other certification standards.

- Customer Service: We provide comprehensive after-sales service to address customer concerns. Our experienced technical team offers professional consultation and guidance, establishing a robust customer service system to ensure a quality service experience.

Features of 5056 Cold Finished Aluminum Wire Rod Bar

- High Strength and Excellent Formability: The 5056 aluminum alloy exhibits good strength and formability during cold heading, withstanding high processing pressures and forming into complex components such as rivets, screws, and other fasteners.

- Corrosion Resistance: Its superior seawater and saltwater corrosion resistance make 5056 aluminum alloy an ideal material for harsh environments (such as marine and low-temperature environments), especially suitable for marine and aerospace components produced via cold heading.

- Good Weldability: The 5056 aluminum bar has excellent weldability, allowing joints formed during cold heading to be securely welded, thus enhancing the overall strength of the final product.

- Ease of Processing and Forming: The 5056 aluminum alloy has good machinability during the cold heading forming process, allowing precise and intricate parts to be produced through cold processing without losing its fundamental strength and corrosion resistance.

- Suitable for High-Precision Parts Production: The 5056 aluminum bar is ideal for precision cold heading applications, particularly for producing high-strength, corrosion-resistant precision components such as screws, rivets, and other high-stress parts.

Optimal Application Fields for 5056 Cold Finished Aluminum Wire Rod Bar

- Marine and Shipbuilding Industry: Due to its outstanding resistance to saltwater corrosion, the 5056 aluminum alloy is highly suitable for ship parts, marine structural components, and other coastal applications, able to withstand harsh marine environments.

- Aerospace Sector: The 5056 aluminum alloy performs well in aerospace components requiring low temperatures and high strength, widely applied in aircraft structural parts, rivets, and cable sheathing.

- Automotive and Transportation: In automotive and transportation manufacturing, 5056 aluminum alloy is used for wiring harnesses, connectors, and structural components, meeting lightweight and corrosion-resistant requirements.

- Construction and Infrastructure: 5056 aluminum alloy is used for building structural supports, frames, reinforcements, and light pole brackets, suitable for long-term outdoor exposure due to its excellent corrosion resistance and moderate strength.

- Industrial Equipment and Machinery Parts: 5056 aluminum alloy has broad applications in high-stress components and precision machinery parts, ideal for scenarios requiring high strength, corrosion resistance, and good machinability.

- Cold Heading Applications: During the cold heading process, the 5056 aluminum alloy is well-suited for manufacturing rivets, bolts, screws, and other fasteners, offering excellent strength and formability.

5056 aluminum bar procurement guide

1. Comprehensive documentation

Msatar can provide detailed quality testing reports, including raw material certificates, laboratory test reports, fumigation reports, specification guides, commercial invoices, and guarantees, ensuring the quality transparency and traceability of each batch of products.

2. Fine export packaging

In international shipping, the quality of packaging directly affects whether goods can rust, corrode, scratch, deform, or suffer other damages during transport. Therefore, high-quality packaging materials are crucial. Msatar has years of export packaging experience, providing safe and reliable packaging solutions for thousands of businesses. By using fumigated wooden boxes, wooden pallets, and other high-quality packaging materials, our packaging damage rate is only one-third of the industry average.

3. Professional loading solutions

Our experienced order-following team can provide flexible and diverse loading solutions, including options for 20/40-foot containers or bulk ships. Regardless of your cargo specifications and shapes, we can customize a refined loading plan that saves an average of 15% container space, effectively reducing your logistics costs.

Product Guide of 5056 aluminum bar

Standard Specifications of 5056 aluminum bar

- EN 573-3 - 2009 Aluminium and aluminium alloys. Chemical composition and form of wrought products. Chemical composition and form of products

- ASTM B211 - Aluminum and Aluminum-Alloy Rolled or Cold Finished Bar, Rod

- ASTM B316 - Standard Specification for Aluminum and Aluminum-Alloy Rivet and Cold-Heading Wire and Rods

- AMS 4182 - Aluminum Alloy, Wire 5.0Mg - 0.12Mn - 0.12Cr (5056-O) Annealed

- AMS-QQ-A-430 - Aluminum Alloy Rod & Wire, for Rivets & Cold Heading

Chemical composition of 5056 aluminum bar(ASTM B211)

| Element | 5056 |

| Si | 0.30 |

| Fe | 0.40 |

| Cu | 0.10 |

| Mn | 0.05-0.20 |

| Mg | 4.5-5.6 |

| Cr | 0.05-0.20 |

| Ni | - |

| Zn | 0.10 |

| Ti | - |

| Remarks | - |

| Others (Each) | 0.05 |

| Others (Total) | 0.15 |

| Al | Rem |

Physical properties of 5056 aluminum bar

| Properties | Value |

| Density | 2.66 g/cm³ |

| Melting point | 568.3 - 638 °C |

| Thermal conductivity | 116 W/m·K |

| Coefficient of thermal expansion | 23.9 µm/m·°C |

| Electrical conductivity | 29 % IACS |

| Properties | O | H111 | H12 | H32 | H14 | H34 | H18 | H38 | H192 | H392 |

| Tensile strength Rm/ksi | 46 | 44 | 46 | 44 | 52 | 50 | 58 | 55 | 60 | 58 |

| Yield strength Rp0.2/ksi | - | - | - | - | - | - | - | - | - | - |

| Elongation | 20% | - | - | - | - | - | - | - | - | - |

Mechanical properties of 5056 Cold-heading aluminum wire and rods(ASTM B316)

| Properties | O | H32 |

| Tensile strength Rm/ksi | 46 | 44-52 |

| Yield strength Rp0.2/ksi | - | - |

| Elongation | - | - |

Why 5056 Cold Finished Aluminum Bar/Rod is Suitable for Cold Heading Applications

- Excellent Formability: The 5056 aluminum alloy exhibits good formability, allowing it to withstand significant deformation during the cold heading process without cracking. This makes it ideal for producing various complex-shaped components, such as rivets, screws, and other fasteners.

- High Strength: The high magnesium content in 5056 aluminum alloy gives it considerable tensile strength even without heat treatment. During the cold heading process, the alloy maintains its strength, ensuring that the produced parts meet structural requirements.

- Outstanding Corrosion Resistance: 5056 aluminum alloy offers excellent resistance to saltwater and atmospheric corrosion, making it especially suitable for marine environments and other harsh conditions. In cold heading applications, many parts need to endure highly corrosive environments for extended periods, and the corrosion resistance of 5056 aluminum alloy provides a significant advantage.

- Good Machinability: 5056 aluminum alloy has good machinability, enabling precise shaping and sizing during the cold heading process, thereby improving production efficiency and part accuracy.

- Suitable for Low-Temperature Environments: 5056 aluminum alloy retains high strength and stability even at low temperatures, making it particularly suitable for cold heading applications requiring low-temperature resistance.

- Weldability: The 5056 aluminum alloy has good weldability, ensuring strong connections between parts formed during the cold heading process. This is especially important for high-precision and high-strength components.

Comparison: 5052 vs. 5056

1.Magnesium Content

5052: Magnesium content is around 2.2% to 2.8%, mainly providing higher corrosion resistance and moderate strength.

5056: Higher magnesium content, typically between 4.5% and 5.5%, resulting in greater strength.

2.Strength

5052: Slightly lower strength than 5056, mainly used in applications requiring good corrosion resistance and moderate strength.

5056: Higher strength due to its higher magnesium content, making it one of the stronger choices among non-heat-treated aluminum alloys.

3.Weldability

5052: Excellent weldability, suitable for most conventional welding processes.

5056: Slightly less weldable than 5052, but still suitable for most standard welding techniques.

4.Machinability

5052: Good machinability but may be less suitable than 5056 for some high-precision machining applications.

5056: Better machinability, ideal for applications requiring precise cutting and machining, especially in cold heading processes.

5.Corrosion Resistance

5052: Very suitable for environments requiring high corrosion resistance, such as marine and chemical environments.

5056: Excellent corrosion resistance, particularly in seawater and saltwater environments, often used in more demanding applications due to its higher strength.

6.Applications

5052: Widely used in ships, vehicles, fuel tanks, and chemical equipment, owing to its good corrosion resistance and moderate strength.

5056: Frequently used in applications requiring high strength and corrosion resistance, such as marine components, aerospace parts, cold heading applications, and structural components exposed to corrosive environments.

In addition to 5056 and 5052, Chalco offers several other aluminum bar alloys that share similar properties in terms of corrosion resistance, weldability, and strength — making them suitable alternatives or complements for various structural, marine, and fastener-related applications.