5454 aluminum rod is an excellent aluminum-magnesium alloy, known for its excellent corrosion resistance and medium to high strength, and is suitable for use in marine and high-temperature environments. The alloy is suitable for use in a variety of industries and excels in applications requiring higher strength and durability, such as chemical storage tanks, shipbuilding and road transport equipment.

Click to view 5454 aluminum bar product guide

Msatar can supply bars of various processes, including extruded bars and cast bars, etc. The specific specifications and sizes are as follows:

- 5454 extrusion aluminum bar

- Temper: O,H111,H112

- DIA: 0.4"-16"(10-420mm)

- Spec: EN 755,ASTM B221,EN 573

- 5454 aluminum cast billets bar

- Temper: F

- DIA: 4.8"-53"(124-1350mm)

- Material used for subsequent extrusion production

Popular products of 5454 aluminum bar

5454 O Aluminum Bar

5454 O Aluminum Bar- 5454 O aluminum rod is an aluminum-magnesium alloy with significant advantages of being soft and easy to form, making it suitable for applications requiring excellent formability. Offers excellent corrosion resistance, especially suitable for marine and chemical environments.

5454 H111 Aluminum Bar

5454 H111 Aluminum Bar- 5454 H111 aluminum bar is slightly work-hardened for increased strength and fatigue resistance, making it ideal for structural applications with high load carrying capacity. It has good corrosion resistance and excellent weldability, and maintains its mechanical properties in operating environments up to 170 degrees Celsius.

5454 H112 Aluminum Bar

5454 H112 Aluminum Bar- 5454 H112 Aluminum Bar has excellent strength after work hardening, suitable for severe load-bearing applications such as road transportation and marine structures. It retains excellent corrosion resistance and can be used in seawater and chemical environments for a long time. Its excellent weldability makes it a versatile structural material.

5454 aluminum square bar

5454 aluminum square bar- Side length: 0.2"-8" (5-200mm)

- 5454 aluminum square bar is widely used in structural parts and road transport equipment due to its high strength and durability. Its square cross section provides good stability and is very suitable for frame and support structure applications.

5454 aluminum rectangular/flat bar

5454 aluminum rectangular/flat bar- Thickness: 0.08"-8" (2-200mm)

- 5454 aluminum rectangular bar has excellent formability and welding properties, making it an ideal material for pressure vessels and tanks. The rectangular structure makes it excellent in applications that require large support areas, especially in the chemical and shipbuilding industries.

5454 aluminum hexagonal bar

5454 aluminum hexagonal bar- DIA: 0.4"-16"(10-420mm)

- 5454 aluminum round bar is an aluminum-magnesium alloy material with good corrosion resistance and high fatigue strength, widely used in chemical storage tanks and marine environments. The round structure of this alloy is easy to process and is particularly suitable for industrial applications that require load-bearing and corrosion resistance.

5454 aluminum round bar

5454 aluminum round bar- Distance across flats: 0.2"-8" (5-200mm)

- 5454 aluminum hexagonal bar is widely used in shipbuilding and industrial equipment due to its easy grip and stable geometry. The hexagonal structure makes it ideal for complex structures and custom components, and has excellent corrosion resistance.

5454 Large diameter aluminum rod

5454 Large diameter aluminum rod- DIA: 4.8"-53"(124-1350mm)

- 5454 Large diameter aluminum rod is designed for high strength and durability requirements, ensuring stability and reliability in high-load applications. Suitable for applications in heavy machinery and marine environments.

In addition to 5454 aluminum bars, Mastar also supplies a wide range of aluminum bar alloys in various shapes such as round bars, square bars, flat bars, and hex bars. If you are looking for alternatives with similar machinability or mechanical strength, feel free to explore our whole aluminum bar product pages or contact us for assistance.Quick Quote

What we provide as a high-quality aluminum bar supplier

- Premium Products: Using high-quality aluminum billets and precise alloying and heat treatment processes, we optimize strength and ductility, ensuring uniform cooling and annealing. This guarantees high tensile strength and excellent performance.

- Grain Control: Reverse extrusion and controlled cooling keep grain size within ≤0.5mm, improving consistency and reducing defects. We also offer precision ground aluminum bars for high-precision applications requiring tight tolerances and fine surface finish.

- Timely Delivery: With a 10,000-ton inventory, standard sizes are ready for immediate dispatch. Advanced equipment and a skilled team ensure fast production cycles and reliable logistics for on-time delivery.

- Competitive Pricing: We support both retail and bulk procurement for metal distributors, offering discounts and rebate policies for B2B customers. Transparent pricing ensures our aluminum bar quality comes at a price advantage.

- Comprehensive Quality Testing: We implement strict multi-step testing, including tensile strength, elongation, ultrasonic testing, and metallographic inspection, ensuring that our aluminum bars meet AMS, EN, and NADCAP standards.

- Customer Service: We provide complete after-sales support, addressing customer concerns with an experienced technical team offering professional advice and guidance, and an established customer service system to guarantee an exceptional service experience.

Features of 5454 aluminum bar

- Medium to high strength: suitable for applications in high load environments.

- Corrosion resistance: excellent chemical corrosion resistance in chemical environments and marine conditions.

- Good weldability: suitable for a variety of welding processes, such as TIG and MIG, to ensure the firmness of the welded structure.

- Excellent formability: suitable for processing complex shapes.

- High fatigue strength: excellent durability under long-term stress.

For projects with similar performance requirements, you may also consider other aluminum bar alloys such as the 5A06 aluminum bar for enhanced strength and welding performance, the 6061 aluminum bar for its balance of strength and machinability, or the 5083 aluminum bar for its excellent corrosion resistance in demanding environments.

Best applications 5454 aluminum bar

Automotive and Road Transport

Automotive and Road Transport- In the automotive and road transport sectors, 5454 aluminum is used to manufacture tanks, freight cars, and transport tank structures due to its high strength and good corrosion resistance. This material effectively reduces the overall weight and extends the service life of the equipment.

Chemical and Storage Tank Manufacturing

Chemical and Storage Tank Manufacturing- 5454 aluminum is widely used in chemical plant equipment due to its excellent chemical corrosion resistance, especially in the manufacture of chemical transportation and storage tanks. Its high strength and good formability enable it to cope with high temperatures and harsh chemical environments.

Marine and Offshore Applications

Marine and Offshore Applications- 5454 aluminum performs particularly well in marine applications. Its resistance to saltwater corrosion makes it ideal for ship hulls, offshore platforms, and other marine structures.

5454 aluminum bar procurement guide

1.Comprehensive documentation

Msatar can provide detailed quality testing reports, including raw material certificates, laboratory test reports, fumigation reports, specification guides, commercial invoices, and guarantees, ensuring the quality transparency and traceability of each batch of products.

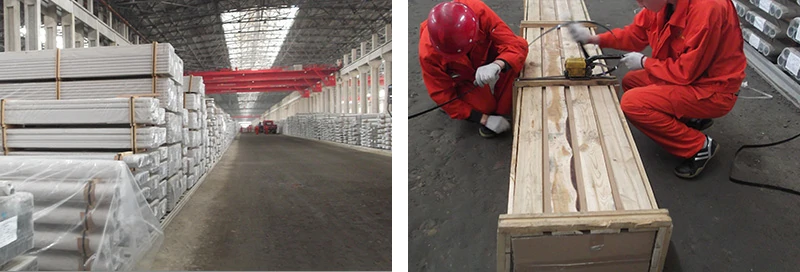

2.Fine export packaging

In international shipping, the quality of packaging directly affects whether goods can rust, corrode, scratch, deform, or suffer other damages during transport. Therefore, high-quality packaging materials are crucial. Msatar has years of export packaging experience, providing safe and reliable packaging solutions for thousands of businesses. By using fumigated wooden boxes, wooden pallets, and other high-quality packaging materials, our packaging damage rate is only one-third of the industry average.

3.Professional loading solutions

Our experienced order-following team can provide flexible and diverse loading solutions, including options for 20/40-foot containers or bulk ships. Regardless of your cargo specifications and shapes, we can customize a refined loading plan that saves an average of 15% container space, effectively reducing your logistics costs.

Knowledge center for 5454 aluminum bar

Specification for 5454 aluminum bar

- EN 573-3 - 2009 Aluminium and aluminium alloys. Chemical composition and form of wrought products. Chemical composition and form of products

- EN 755-2 - 2008 Aluminium and aluminium alloys. Extruded rod/bar, tube and profiles. Mechanical properties

- ASTM B221 - Aluminum and Aluminum-Alloy Extruded Bars, Rods, Wire, Profiles, and Tubes

Chemical composition of 5454 aluminum bar

| Element | Value |

| Si | 0.25 |

| Fe | 0.40 |

| Cu | 0.10 |

| Mn | 0.5-1.0 |

| Mg | 2.4-3.0 |

| Cr | 0.05-0.20 |

| Zn | 0.25 |

| Ti | 0.20 |

| Remarks | - |

| Others (Each) | 0.05 |

| Others (Total) | 0.15 |

| Al | Rem |

Physical properties of 5454 aluminum bar

| Properties | value |

| Density | 2.69 g/cm³ |

| Melting point | 645°C |

| Thermal conductivity | 135 W/m·K |

| Coefficient of thermal expansion | 23.6 µm/m·°C |

| Electrical conductivity | 34 % IACS |

Mechanical properties of 5454 aluminum bar(EN 755-2)

| Properties | O | H111 | H112 |

| Tensile strength Rm/Mpa | 200-275 | 200-275 | 200 |

| Yield strength Rp0.2/Mpa | 85 | 85 | 85 |

| Elongation | 16-18% | 16-18% | 14-16% |

| Hardness | 60 | 60 | 60 |

5052 vs 5454

| Properties | 5052 | 5454 |

| Main alloying elements | Magnesium (Mg), Chromium (Cr) | Magnesium (Mg) |

| Tensile strength | 210-260 MPa | 290-350 MPa |

| Weldability | Excellent | Good |

| Processability | Good | Difficult |

| Corrosion resistance | Excellent | Good |

| Density | 2.68 g/cm³ | 2.71 g/cm³ |

| Hardness | 60 | 70 |

- Strength and weldability: The tensile strength of 5454 aluminum is higher than that of 5052 aluminum, but 5052 aluminum has better weldability and is suitable for applications that require frequent welding.

- Processability: 5052 aluminum is easy to process and suitable for the manufacture of complex shapes, while 5454 aluminum is relatively difficult to process due to its higher hardness.

- Corrosion resistance: 5052 aluminum performs better in corrosion resistance and is suitable for use in humid environments, while 5454 aluminum is better but not as good as 5052 in extreme environments.

- Cost: 5052 aluminum has a relatively low cost due to fewer alloying elements, and has an advantage in terms of economy.

In general, 5052 aluminum is more outstanding in weldability and corrosion resistance, and is suitable for products with high requirements for lightweight and corrosion resistance, while 5454 aluminum is suitable for applications with higher structural requirements due to its higher strength.

5454 vs 6061

| Properties | 5454 | 6061 |

| Main alloying elements | Magnesium (Mg) | Magnesium (Mg), Silicon (Si) |

| Tensile strength | 290-350 MPa | 260-310 MPa |

| Weldability | Good | Excellent |

| Processability | Difficult | Good |

| Corrosion resistance | Good | Good |

| Density | 2.71 g/cm³ | 2.70 g/cm³ |

| Hardness | 70 | 95 |

- Strength and corrosion resistance: The tensile strength of 5454 aluminum is higher than that of 6061 aluminum, and it is suitable for structural applications with high load requirements, while 6061 aluminum is similar to 5454 aluminum in corrosion resistance, and both are suitable for a variety of environments.

- Weldability: The welding performance of 6061 aluminum is better than that of 5454 aluminum, and it is particularly suitable for welded structures, but 5454 aluminum still has good weldability under certain environments.

- Processability: 6061 aluminum has more advantages in processability, is easy to form and machine, and is suitable for more complex design requirements.

- Cost: The production cost of 6061 aluminum is relatively low, suitable for large-scale production, and has a good cost-effectiveness.

Overall, 5454 aluminum is better than 6061 aluminum in strength and is more suitable for heavy-duty and structural applications, while 6061 aluminum is suitable for a wide range of industrial applications due to its excellent processability and weldability.

Why is 5454 alloy suitable for marine applications?

5454 aluminum alloy is very suitable for use in marine environments due to its unique chemical composition and physical properties. The main reasons are as follows:

1. Excellent corrosion resistance: 5454 aluminum alloy contains a high magnesium content, which makes it perform well in seawater and humid environments. Magnesium can significantly improve the corrosion resistance of aluminum alloys, prevent oxidation or corrosion in marine environments, and extend the service life of the material.

2. Higher tensile strength: 5454 alloy has a tensile strength of 290-350 MPa, which is higher than other aluminum alloys. This means that 5454 alloy can maintain good structural integrity when withstanding wind, waves and impact forces, making it suitable for use as hulls, offshore platforms and other marine structures.

3. Good weldability: Although the weldability of 5454 alloy is slightly worse than some aluminum alloys, it still has good weldability. Welding is a common connection method in marine applications, so 5454 alloy is practical in manufacturing and repairing ships and marine facilities.

4. Fatigue resistance: In the marine environment, materials are often subjected to repeated stress. 5454 aluminum alloy has good fatigue resistance, allowing it to withstand constant dynamic loads without fatigue damage during long-term use.

5. Lightweight: 5454 alloy is lighter than traditional materials such as steel, which is an important advantage in marine applications. Lightweighting not only helps reduce transportation costs but also improves the fuel efficiency of a ship or marine facility.

In addition to 5454, Chalco offers other marine-grade aluminum bar alloys with comparable strength, corrosion resistance, and fatigue performance — providing engineers with more flexible material options for hull structures, decks, and offshore components.