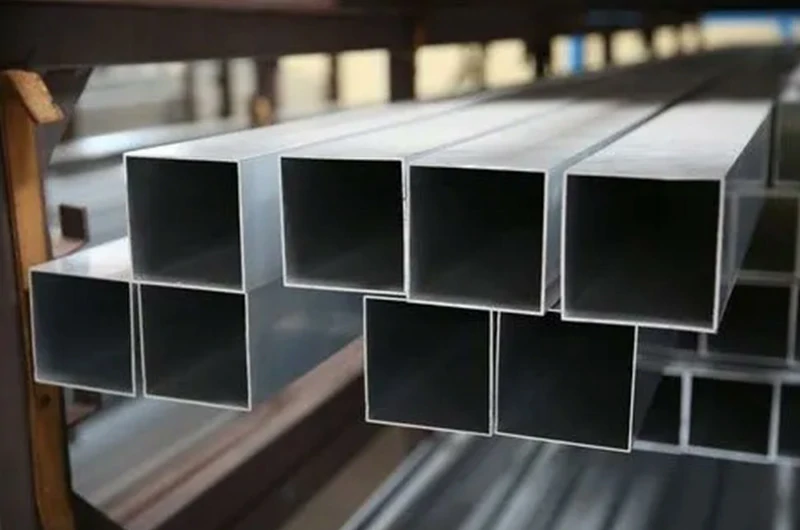

6061 aluminum square tube is an aluminum alloy tube with a square cross-section made from 6061 aluminum alloy. It features high strength, good corrosion resistance, and ease of welding and machining. It is widely used in structural applications, frameworks, and mechanical components across industries such as construction, automotive, and aerospace.

Use our weight calculator to reliably estimate the weight of aluminum alloy products. From sheets, tubes, bars, to simple profiles, Mastar Metal can provide you with the answers.

First, select an alloy, fill in the other required information, and the system will calculate the weight of the aluminum material for you.

Start by choosing an alloy...

*All weights shown using this metal weight calculator are for guidance only.

Common types of 6061 aluminum square tube

6061 Extruded Aluminum Square Tube

6061 Extruded Aluminum Square Tube- The 6061 aluminum alloy tube produced by extrusion process is the most common.

- Features: high strength, corrosion resistance, precise size

- Application: used for structural parts such as building frames, doors and windows, railings and support beams.

6061 telescoping aluminum square tubing

6061 telescoping aluminum square tubing- 6061 telescopic aluminum square tube is an aluminum alloy pipe with high strength and corrosion resistance. It is designed to interconnect different-sized fittings, allowing for flexible length adjustments. It is widely used in adjustable brackets, outdoor equipment, and telescopic structures.

6061 anodized aluminum square tube

6061 anodized aluminum square tube- 6061 anodized aluminum square tube is an anodized aluminum alloy tube with excellent corrosion resistance and beautiful surface. It is widely used in construction, decoration and industrial fields. Click to find more anodized tube products in Mastar.

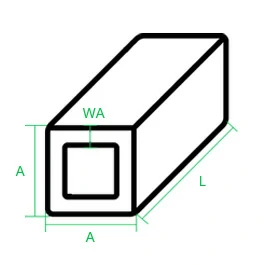

Popular size references for 6061 aluminum square tubes

Mastar can provide customers with 6061 aluminum square tubes in various sizes, support customization, and can cut the same size in different lengths. The following are the sizes that customers often choose.

| Product | Width(W) | Thickness(T) |

| 0.75" x 0.062" aluminum square tubes 6061-T6-extruded | 0.75" | 0.062" |

| 1.5" x 0.062" aluminum square tubes 6061-T6-extruded | 1.5" | 0.062" |

| 2" x 0.062" aluminum square tubes 6061-T6-extruded | 2" | 0.062" |

| 1" x 0.065" aluminum square tubes 6061-T6-extruded | 1" | 0.065" |

| 1" x 0.125" aluminum square tubes 6061-T6-extruded | 1" | 0.125" |

| 1.25" x 0.125" aluminum square tubes 6061-T6-extruded | 1.25" | 0.125" |

| 1.5" x 0.125" aluminum square tubes 6061-T6-extruded | 1.5" | 0.125" |

| 2" x 0.125" aluminum square tubes 6061-T6-extruded | 2" | 0.125" |

| 2.5" x 0.125" aluminum square tubes 6061-T6-extruded | 2.5" | 0.125" |

| 1.75" x 0.125" aluminum square tubes 6061-T6-extruded | 1.75" | 0.125" |

| 3" x 0.125" aluminum square tubes 6061-T6-extruded | 3" | 0.125" |

| 4" x 0.125" aluminum square tubes 6061-T6-extruded | 4" | 0.125" |

| 1.5" x 0.1875" aluminum square tubes 6061-T6-extruded | 1.5" | 0.1875" |

| 2" x 0.1875" aluminum square tubes 6061-T6-extruded | 2" | 0.1875" |

| 4" x 0.1875" aluminum square tubes 6061-T6-extruded | 4" | 0.1875" |

| 6" x 0.1875" aluminum square tubes 6061-T6-extruded | 6" | 0.1875" |

| 5" x 0.188" aluminum square tubes 6061-T6-extruded | 5" | 0.188" |

| 2" x 0.25" aluminum square tubes 6061-T6-extruded | 2" | 0.25" |

| 1.5" x 0.25" aluminum square tubes 6061-T6-extruded | 1.5" | 0.25" |

| 2.5" x 0.25" aluminum square tubes 6061-T6-extruded | 2.5" | 0.25" |

| 3" x 0.25" aluminum square tubes 6061-T6-extruded | 3" | 0.25" |

| 4" x 0.25" aluminum square tubes 6061-T6-extruded | 4" | 0.25" |

| 5" x 0.25" aluminum square tubes 6061-T6-extruded | 5" | 0.25" |

| 3.5" x 0.25" aluminum square tubes 6061-T6-extruded | 3.5" | 0.25" |

| 6" x 0.25" aluminum square tubes 6061-T6-extruded | 6" | 0.25" |

| 8" x 0.25" aluminum square tubes 6061-T6-extruded | 8" | 0.25" |

| 4" x 0.375" aluminum square tubes 6061-T6-extruded | 4" | 0.375" |

| 6" x 0.375" aluminum square tubes 6061-T6-extruded | 6" | 0.375" |

| 8" x 0.375" aluminum square tubes 6061-T6-extruded | 8" | 0.375" |

| 4" x 0.5" aluminum square tubes 6061-T6-extruded | 4" | 0.5" |

| 6" x 0.5" aluminum square tubes 6061-T6-extruded | 6" | 0.5" |

| 1-1/2" x 1/16" aluminum square tubes 6061-T6-extruded | 1-1/2" | 1/16" |

| 1-1/2" x 1/4" aluminum square tubes 6061-T6-extruded | 1-1/2" | 1/4" |

| 2" x 1/4" aluminum square tubes 6061-T6-extruded | 2" | 1/4" |

| 2-1/2" x 1/4" aluminum square tubes 6061-T6-extruded | 2-1/2" | 1/4" |

| 3" x 1/4" aluminum square tubes 6061-T6-extruded | 3" | 1/4" |

| 1" x 1/8" aluminum square tubes 6061-T6-extruded | 1" | 1/8" |

| 1-1/4" x 1/8" aluminum square tubes 6061-T6-extruded | 1-1/4" | 1/8" |

| 1-1/2" x 1/8" aluminum square tubes 6061-T6-extruded | 1-1/2" | 1/8" |

| 2" x 1/8" aluminum square tubes 6061-T6-extruded | 2" | 1/8" |

| 2-1/2" x 1/8" aluminum square tubes 6061-T6-extruded | 2-1/2" | 1/8" |

| 3" x 1/8" aluminum square tubes 6061-T6-extruded | 3" | 1/8" |

| 4" x 1/8" aluminum square tubes 6061-T6-extruded | 4" | 1/8" |

| 1-1/2" x 3/16" aluminum square tubes 6061-T6-extruded | 1-1/2" | 3/16" |

| 2" x 3/16" aluminum square tubes 6061-T6-extruded | 2" | 3/16" |

| 2-1/2" x 3/16" aluminum square tubes 6061-T6-extruded | 2-1/2" | 3/16" |

| 3" x 3/16" aluminum square tubes 6061-T6-extruded | 3" | 3/16" |

Click to see all

Click to see all If none of the popular sizes above match your desired size, please contact us and we will quickly find the right size in stock.

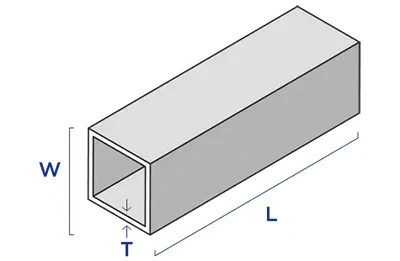

Dimensional tolerances of 6061 aluminum square tubes

The tolerance standard of Mastar's aluminum square tubes strictly follows the EN755 tolerance specification.

Height tolerance

| Alloy - Temper | Method | Spec. Height, in. | Height Tol. (at corners) | Height Tol. (not at corners) |

| 6061-T6 | Extruded | 0.500 to 0.749 | +/- 0.012" | +/- 0.020" |

| 6061-T6 | Extruded | 0.750 to 0.999 | +/- 0.014" | +/- 0.020" |

| 6061-T6 | Extruded | 1.000 to 1.999 | +/- 0.018" | +/- 0.025" |

| 6061-T6 | Extruded | 2.000 to 3.999 | +/- 0.025" | +/- 0.035" |

| 6061-T6 | Extruded | 4.000 to 4.999 | +/- 0.035" | +/- 0.045" |

| 6061-T6 | Extruded | 5.000 to 5.999 | +/- 0.045" | +/- 0.055" |

| 6061-T6 | Extruded | 6.000 to 6.999 | +/- 0.055" | +/- 0.065" |

| 6061-T6 | Extruded | 7.000 to 7.999 | +/- 0.065" | +/- 0.075" |

| 6061-T6 | Extruded | 8.000 to 8.999 | +/- 0.075" | +/- 0.085" |

| 6061-T6 | Extruded | 9.000 to 9.999 | +/- 0.085" | +/- 0.095" |

| 6061-T6 | Extruded | 10.000 to 10.999 | +/- 0.095" | +/- 0.105" |

| 6061-T6 | Extruded | 11.000 to 12.999 | +/- 0.105" | +/- 0.115" |

Wall thickness tolerance

| Alloy-Temper | Method | Wall(inch) | Circumscribing Circle Dia. Under 5.000(Height ≤ 3.5") Wall tolerance | Circumscribing Circle Dia.5.000 and over(Height > 3.5") Wall tolerance |

| 6061-T6 | Extruded | Under 0.047 | +/- 0.005" | +/- 0.008" |

| 6061-T6 | Extruded | 0.047 to 0.061 | +/- 0.006" | +/- 0.009" |

| 6061-T6 | Extruded | 0.062 to 0.124 | +/- 0.007" | +/- 0.010" |

| 6061-T6 | Extruded | 0.125 to 0.249 | +/- 0.008" | +/- 0.015" |

| 6061-T6 | Extruded | 0.250 to 0.374 | +/- 0.011" | +/- 0.020" |

| 6061-T6 | Extruded | 0.375 to 0.499 | +/- 0.014" | +/- 0.030" |

| 6061-T6 | Extruded | 0.500 to 0.749 | +/- 0.025" | +/- 0.040" |

| 6061-T6 | Extruded | 0.750 to 0.999 | +/- 0.035" | +/- 0.050" |

| 6061-T6 | Extruded | 1.000 to 1.499 | +/- 0.045" | +/- 0.060" |

| 6061-T6 | Extruded | 1.500 to 2.000 | ... | +/- 0.070" |

Comparison of 6061 Aluminum Round, Square, and Rectangular Tubes

- 6061 Round Tube: Ideal for fluid transport systems, pneumatic lines, and cylindrical structural components. Its circular shape offers even stress distribution and better pressure resistance. Also available in thin-wall pipes and thick-wall tubes for varying pressure needs.

- 6061 Square Tube: Best suited for load-bearing applications such as frames, supports, and architectural structures. Its flat surfaces allow easy joining and greater rigidity. Consider pairing with threaded pipe or pipe tee fittings for modular assemblies.

- 6061 Rectangular Tube: Provides balanced strength and aesthetic appeal in space-constrained projects like furniture, solar brackets, and conveyor frames. Offers improved material efficiency and tight-fitting layouts. Available in anodized finishes or custom coil tube formats.

For more product details, specifications, and processing options, feel free to visit our 6061 aluminum tube overview page or contact our sales team to get expert support and tailored solutions for your project. Quick Quote

Specific applications of 6061 square aluminum tube in different fields

Construction engineering: Used for structural components such as building frames, doors and windows, curtain walls, stairs, railings, and balconies, providing good strength and corrosion resistance.

Machinery manufacturing: Widely used in frames and supports for machinery, ensuring equipment stability and durability.

Transportation: Utilized in vehicles, ships, and aerospace for chassis and structural components, reducing weight and improving efficiency.

Furniture manufacturing: Used to create lightweight and durable furniture like tables and shelves, with a clean appearance suitable for modern design.

Solar mounting systems: Applied in outdoor solar mounting systems, with strong weather resistance and a long lifespan.

Sports equipment: Used in items like bicycle frames and fitness equipment, being lightweight and durable.

Mechanical properties of 6061 aluminum square tube

| Hardness, Brinell | 95HB |

| Tensile Strength, Ultimate | 310MPa |

| Tensile Strength, Yield | 276MPa |

| Notched Tensile Strength | 324MPa |

| Ultimate Bearing Strength | 607MPa |

| Bearing Yield Strength | 386Mpa |

| Elongation | 17% |

Production process of 6061 aluminum square tube

Raw material preparation: Select and preheat high-quality 6061 aluminum alloy ingots to prepare for extrusion.

Extrusion forming: Extrusion is the key process for shaping aluminum square tubes. After preheating the ingots, they are extruded through a die under high pressure to form tubes with a square cross-section. Different sizes and wall thicknesses can be produced by changing the die.

Cooling treatment: Rapidly cool the extruded profiles to prevent cracking and deformation.

Stretch straightening: Slightly stretch the profiles to eliminate internal stress and improve straightness and dimensional accuracy.

Cutting processing: Cut the long profiles to the required lengths, ensuring smooth edges.

Heat treatment (T6): Enhance material strength and hardness through solution treatment, quenching, and aging.

Surface treatment: Conduct anodizing, electrophoretic coating, or powder coating as needed to improve corrosion resistance and aesthetics.

Quality inspection: Perform checks on dimensions, mechanical properties, and surface quality to ensure compliance with specifications.

Packaging and storage: Properly package and store in an appropriate environment to prevent damage during transportation and storage.

What surface treatments can Mastar's 6061 rectangular aluminum tube undergo?

Mastar's 6061 rectangular aluminum tube can undergo surface treatments such as anodizing, powder coating, polishing, and sandblasting. Colors can be selected freely, offering strong customization options.

What services can Mastar provide for you?

Multi-specification product supply: Mastar offers aluminum square tubes in various sizes, wall thicknesses, and surface treatments to meet the needs of industries such as construction, machinery, furniture, and transportation, ensuring a wide range of choices for customers.

Custom processing services: In addition to standard products, Mastar provides custom cutting, surface treatments (such as sandblasting, polishing, and anodizing), and other processing services based on specific customer requirements, ensuring that products fully meet project needs.

High-quality assurance: Mastar has a strict quality control system that meticulously manages every step from raw material procurement to production and finished product inspection, ensuring aluminum square tubes have excellent strength, precision, and corrosion resistance, meeting various industry standards.

Fast production and delivery: With efficient production processes, Mastar can shorten production cycles and provide timely logistics services, ensuring customers receive the required aluminum square tube products within their project timelines.

Technical support and consultation: The company has a professional technical team that offers detailed product advice, helping customers select the most suitable aluminum tube materials, specifications, and surface treatments for their projects, ensuring smooth project execution.

Click to collapse

Click to collapse