Aluminum alloy threaded pipes are known for their superior corrosion resistance and are lighter than steel or copper. This property of aluminum allows the aluminum pipe to be quickly and permanently combined with the joint to form a reliable connection, which is widely used in indoor and outdoor scenes such as pipes, racks, railings, and compressed air systems to ensure a safe and leak-free piping system.

With its lightness and durability, aluminum alloy threaded pipes are an ideal choice for many engineering projects. MASTAR aluminum alloy threaded pipes have a wide variety of products to meet the needs of different industries:

Aluminum threaded pipe hot selling products

Mastar's aluminum threaded pipes are primarily manufactured from high-strength alloys such as 6061, 6063, and 6082, offering excellent machinability and corrosion resistance. These pipes are available in various wall thickness standards like SCH40 and SCH80, and can be supplied in seamless, welded, or surface-treated forms to match different structural and fluid handling requirements. For projects involving both threaded and non-threaded components, you may also explore our broader range of aluminum pipe types and specifications, including straight tubes, elbows, and customized profiles.

Internal thread pipe

Internal thread pipe- The internal thread aluminum tube has threads inside, which is convenient for connecting with other external thread pipe fittings and is widely used in fluid transmission systems. This design can ensure the sealing and connection stability, and is usually used in smaller fluid pipeline systems.

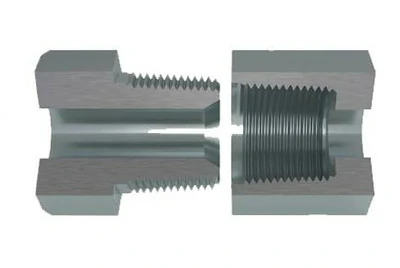

External thread pipe

External thread pipe- Externally threaded aluminum pipes have threads on the outside that can be connected to internally threaded fittings. This type of pipe is often used in situations where quick disassembly and assembly is required, such as maintenance and installation. In addition, externally threaded pipes are generally suitable for low-pressure applications.

Threaded pipe at both ends

Threaded pipe at both ends- The internal thread aluminum tube has threads inside, which is convenient for connecting with other external thread pipe fittings and is widely used in fluid transmission systems. This design can ensure the sealing and connection stability, and is usually used in smaller fluid pipeline systems.

Single threaded pipe

Single threaded pipe- Single-end threaded pipes have threads on one end and a smooth cut on the other end, suitable for connecting to other non-threaded pipes or equipment. They are often used to connect equipment to pipes to simplify the installation process.

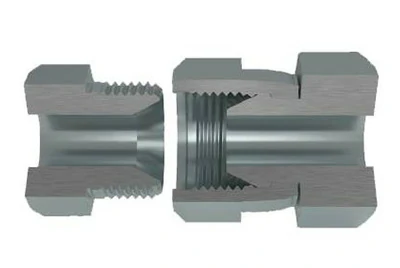

Aluminum shaft coupling

Aluminum shaft coupling- Aluminum couplings are used to connect two aluminum pipes or other pipes and meet the ASM 6061-T6 standard. This material has excellent strength and corrosion resistance and is generally used in lightweight applications. Stock sizes range from 1/4 inch to 4 inches to accommodate the needs of different piping systems.

| MASTAR aluminum threaded pipe hot sale size reference table | ||||||

| Outer Diameter (OD) | Wall Thickness SCH40 | Inner Diameter SCH40 | Wall Thickness SCH80 | Inner Diameter SCH80 | Thread Type | Thread Length |

| 0.84" (1/2" NPS) | 0.109" | 0.622" | 0.147" | 0.546" | NPT | 1/2" |

| 1.05" (3/4" NPS) | 0.113" | 0.824" | 0.154" | 0.742" | NPT | 1/2" |

| 1.315" (1" NPS) | 0.133" | 1.049" | 0.179" | 0.957" | NPT | 3/4" |

| 1.66" (1 1/4" NPS) | 0.14" | 1.38" | 0.191" | 1.278" | NPT | 3/4" |

| 1.9" (1 1/2" NPS) | 0.145" | 1.61" | 0.2" | 1.5" | NPT | 1" |

| 2.375" (2" NPS) | 0.154" | 2.067" | 0.218" | 1.939" | NPT | 1" |

| 2.875" (2 1/2" NPS) | 0.203" | 2.469" | 0.276" | 2.323" | NPT | 1.25" |

Aluminum threaded pipe fittings

To ensure a complete and compatible connection system, Mastar offers a full range of aluminum threaded pipe fittings made from durable alloys such as 6061-T6 and 5083. These fittings—including elbow bends, tees, reducers, and caps—are essential connectors for aluminum alloy threaded pipes, allowing for flexible layouts and reliable sealing across different space constraints and application scenarios. For projects that require welded alternatives or enhanced sealing performance, you may also explore our broader selection of aluminum welding pipe products.

What are the characteristics of aluminum threaded pipe fittings

- Corrosion resistance: Aluminum alloy surface naturally forms an oxide film, which can resist corrosion from most chemicals and is suitable for humid and corrosive environments.

- Strength: Despite its lightness, aluminum alloy is strong enough to withstand high pressures and is suitable for use in demanding piping systems.

- Good connection performance: The thread design allows aluminum alloy threaded pipe fittings to be quickly and firmly connected to aluminum alloy threaded pipes, ensuring good sealing.

- Excellent processing performance: Aluminum alloy is easy to process and form, and can meet the requirements of various complex designs. It can be designed into various types (such as elbows, tees, etc.) according to needs to meet different pipeline layouts and application requirements.

How to ensure the compatibility of aluminum threaded pipe fittings and aluminum threaded pipes

- Matching: The thread size and specifications of aluminum alloy threaded pipe fittings are usually matched with aluminum alloy threaded pipes to ensure good connection and sealing.

- Material consistency: Using the same material for fittings and pipes helps avoid galvanic corrosion issues and extends the life of the entire system.

- System integrity: The combination of aluminum alloy threaded pipes and fittings can achieve more flexible pipeline layout to adapt to different installation environments and needs.

- Easy installation: The combination of aluminum alloy threaded fittings and pipes simplifies the installation process and can usually be connected quickly, saving time and cost.

- Supplier selection: When selecting a supplier, you should choose a supplier that provides both threaded pipes and pipe fittings to ensure the integrity of the size and project. MASTAR has a complete inventory of products and has become the preferred supplier of aluminum alloy threaded pipes and threaded pipe fittings for many industries.

- Aluminum threaded pipe cap

- Aluminum threaded connector

- Aluminum Threaded Elbow

- Sch40 full thread pipe fitting

- Aluminum threaded tee

- Internally or externally threaded pipe inserts

Aluminum threaded fin tube

Our threaded finned tubes are typically made from 6063 or 5052 aluminum alloy, combining internal spiral threads with external fins to significantly improve thermal performance in HVAC and refrigeration systems. These tubes are often used in air conditioning units, condensers, and other heat exchange structures. If your project involves broader heat management needs, you may also consider our full selection of aluminum fin tube solutions tailored for efficient thermal conductivity and corrosion resistance.

- Aluminum alloy internal thread fin tube is a kind of tube designed for efficient heat transfer. It combines the lightness and corrosion resistance of aluminum, and uses internal thread and external fin structure to significantly improve heat exchange performance, and is widely used in refrigeration and heating systems.

- High heat transfer efficiency: The internal threads increase fluid disturbance and the fins increase the surface area, significantly improving heat transfer efficiency.

- Lightweight and corrosion-resistant: Aluminum alloy is lightweight and resistant to oxidation, making it suitable for corrosive environments.

- Good processability: easy to process and customize, suitable for a variety of sizes and shapes.

Application of aluminum internal thread fin tube

It is suitable for air conditioners, condensers, evaporators, industrial heat exchangers and other equipment, and is an important component in HVAC and refrigeration equipment.

Why choose MASTAR aluminum threaded pipe

- Complete alloy supply: We provide various aluminum alloys, including 6061, 6063 and other models that meet various application requirements, ensuring that the materials can adapt to the technical requirements and working environment of different projects.

- Production and quality assurance: The entire quality inspection process includes thread accuracy testing, corrosion resistance testing and durability analysis, as well as inspections for burrs and surface defects to ensure that the product meets high standards in both structural strength and appearance.

- High-precision machining: We use advanced equipment and technology to ensure the accuracy and consistency of thread machining, effectively improving product connection performance and sealing effect.

- Professional customization service: Flexible customization service covers a variety of alloys, sizes and thread designs, quickly meeting customers' specific needs and shortening project delivery cycles.

- Additional processing services: Provide additional services such as surface treatment, welding, cutting, etc. to meet various processing needs in one stop, which is convenient for reducing subsequent processing steps.

- Complete after-sales support: Quickly respond to customer needs, ensure timely delivery of products and provide long-term technical support to help customers efficiently solve problems during use.

Aluminum threaded pipe buying guide

1.NPT threaded pipe and NPS threaded pipe

When purchasing threaded pipes, we often encounter the markings NPT and NPS.

NPS (National Pipe Straight) and NPT (National Pipe Tapered) are thread standards . They specify the type, shape, and size of threads that can be used for different types of pipe connections. Although NPT and NPS are thread standards, they are often used in piping systems and are therefore often used in conjunction with pipe standards. For example, a pipe can be selected based on size and material, but the type of thread for the connection needs to follow the NPT or NPS standard.

| NPT | NPS | |

|  | |

| Definition | NPT threaded pipes adopt the NPT standard and have tapered threads. The diameter of the thread gradually decreases from one end to the other. | NPS threaded pipe adopts NPS standard, has straight thread, the diameter of internal and external thread is consistent, and there is no taper. |

| Features | Tapered Design: The taper is 1/16 inch (about 1.8 degrees) per inch, so the threads gradually tighten during mating connection, forming a self-locking and sealing effect. Sealing: It is usually used in combination with sealants (such as PTFE tape) to further enhance the sealing effect. It is suitable for piping systems that transport liquids and gases. | Straight thread design: The thread does not shrink, so it does not have sealing properties. It is usually combined with flanges, gaskets and other accessories to achieve mechanical connection rather than sealing. Connection method: Commonly used for fixed connections that require higher strength and rigidity, mainly used for mechanical or structural connections. |

| Application | Suitable for applications with high requirements on sealing, such as liquid and gas pipelines in the oil, natural gas, chemical and other industries. | Suitable for use in situations where high sealing is not required, such as hydraulic systems, fixed pipe supports, and low-pressure fluid systems. |

2.Several size parameters that need to be paid attention to when purchasing threaded aluminum tubes

- Outside diameter (OD): The outside diameter of the aluminum tube, usually measured in millimeters (mm).

- Wall thickness: The thickness of the aluminum tube wall affects the strength and weight of the tube.

- Length: The total length of the aluminum tube, usually expressed in meters (m) or millimeters (mm).

- Inside diameter (ID): The diameter of the inside of the aluminum tube, which is determined by the outer diameter and wall thickness.

- Thread specifications: including pitch, thread type (for example: national standard thread, imperial thread, etc.) and thread length.

- Material specifications: such as the specific model of aluminum alloy (for example, 6061, 6063, etc.).

- Weight: The weight per unit length, usually measured in kilograms (kg) or grams (g).

3.Key points for checking the key quality defects of aluminum alloy threaded pipes

- Appearance inspection: Check whether the surface is smooth and whether there are obvious scratches, dents, oxidation and other defects.

- Dimensional measurement: Use tools such as calipers to check the outer diameter, inner diameter and pitch of the threaded pipe to ensure that it meets the design specifications.

- Thread quality inspection: Check the shape, depth, and clarity of the thread to ensure that the thread is intact and free of burrs.

- Physical property testing: such as tensile strength, hardness and ductility testing to ensure that the mechanical properties of the material meet the standards.

- Welding and connection quality inspection: If the threaded pipe has welded or connected parts, the integrity and strength of the welds need to be checked.

- Leak Testing: In some applications, a leak test may be required to ensure the tightness of the pipeline.

4.Material selection for threaded pipe

Successful manufacture of internally threaded aluminum tubes depends on careful selection of the best material, which requires a thorough evaluation of the material's mechanical properties, machinability, and compatibility with the intended use.

A variety of high-performance aluminum alloys combine strength, corrosion resistance, and ease of machinability for a variety of uses. Here is a detailed introduction to some common alloys and their key properties:

- AA6061: Tensile strength >240 MPa, excellent weldability, suitable for aerospace and machinery manufacturing.

- AA5052: Resistant to salt water corrosion, tensile strength ~180 MPa, suitable for marine and chemical environments, but slightly lower weldability.

- AA3003: Good formability, tensile strength ~110 MPa, suitable for decorative pipes and pressure vessels.

5.Selection of processing technology for aluminum alloy threaded pipe

| type | Processing Technology | Advantages | limitation |

| Internal thread pipe | CNC machining | High precision and flexibility for complex geometries | High equipment investment, suitable for mass production |

| Tapping | Cost-effective, easy to use, suitable for standardized threads | Limited ability to process complex threads and low dimensional accuracy | |

| Rotary forging | Less material waste, high thread strength, suitable for thin-walled pipes | Special equipment is required, and process control requirements are high | |

| Combination of technologies | Combining the advantages of different methods to flexibly adapt to various needs | Need to consider thread characteristics, wall thickness, production volume and cost | |

| External thread pipe | CNC machining | High precision, flexibility, suitable for complex external threads | High investment, suitable for mass production |

| Turning | External threads are machined on a lathe to suit most external thread sizes | Not suitable for complex shapes, accuracy depends on equipment and operation | |

| Tapping | Can be used to form preliminary threads when internal and external threads are combined | External thread processing is less dependent on this method |