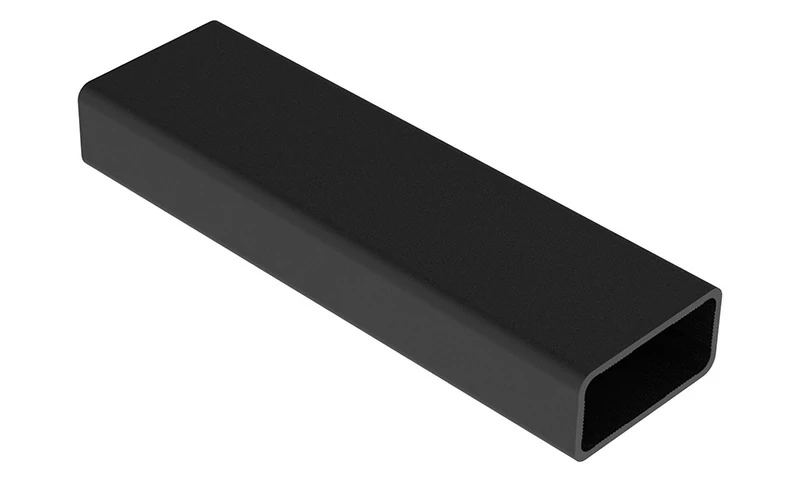

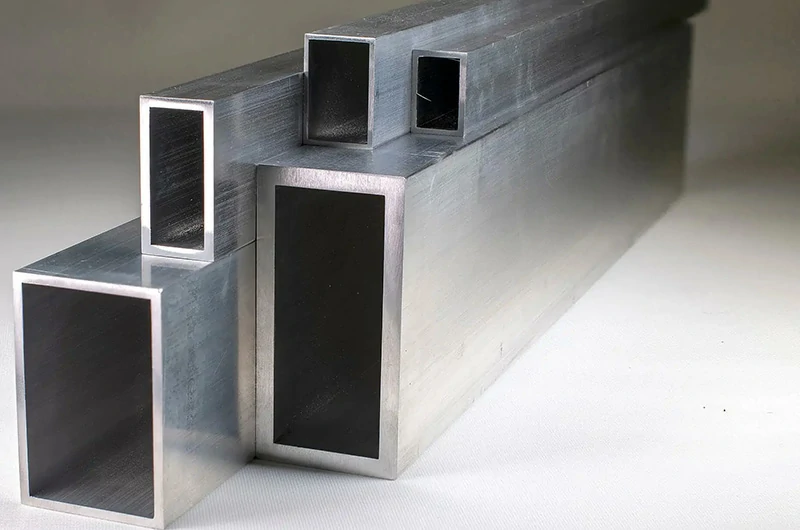

6061 rectangular aluminum tube is an aluminum tube with a rectangular cross-section made from 6061 aluminum alloy. It features excellent strength and rigidity, good corrosion resistance, weldability, and machinability. It is widely used in structural applications requiring lightweight, high strength, and corrosion resistance, such as in construction, manufacturing, and aerospace industries.

Popular 6061 rectangular aluminum tube

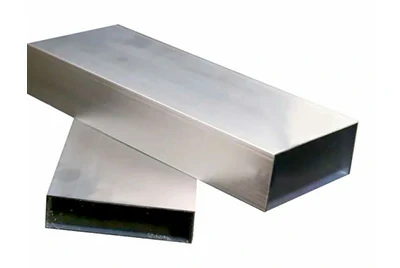

6061 extruded rectangular aluminum tube

6061 extruded rectangular aluminum tube- The 6061 aluminum alloy tube produced by the extrusion process is widely used in construction and industrial fields, with good strength and dimensional accuracy.

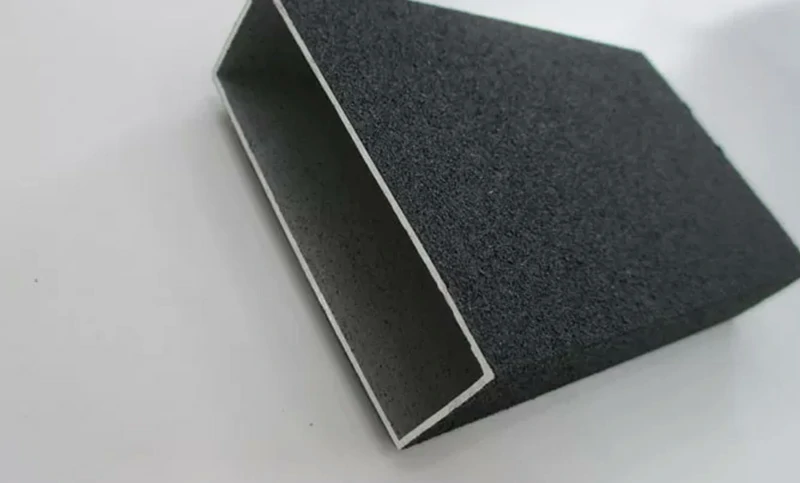

6061 thin-walled rectangular aluminum tube

6061 thin-walled rectangular aluminum tube- Usually refers to 6061 rectangular aluminum tube with a wall thickness of 0.5-2mm, which is widely used in aerospace, automobile manufacturing, outdoor equipment, and guardrails.

- Find more thin wall tube pipe in Mastar.

6061 anodized rectangular aluminum tube

6061 anodized rectangular aluminum tube- 6061 anodized rectangular aluminum tube is an aluminum alloy tube that has undergone anodizing treatment, offering excellent corrosion resistance and an attractive surface. It is widely used in construction, decoration, and industrial fields.

- Find more anodized tube in Mastar.

6061 telescoping aluminum rectangular tubing

6061 telescoping aluminum rectangular tubing- 6061 telescopic rectangular aluminum tube features the ability to nest and extend, making it ideal for applications that require adjustable lengths in structures or supports. Its high strength, lightweight nature, and good corrosion resistance make it widely used in various industries.

Popular size reference for 6061 rectangular aluminum tube

Mastar can provide customers with various sizes of 6061 rectangular aluminum tubes, available in sharp corner and round corner options, with customization supported. Tubes of the same size but different lengths can be cut. Below are the sizes frequently chosen by customers.

| Product | Alloy | Temper | Height(H) | Width(W) | Thickness(T) |

| 1" x 2" x 0.062" Aluminum Rectangle Tube 6061-T6-Extruded | 6061 | T6 | 1" | 2" | 0.062" |

| 1" x 1.5" x 0.125" Aluminum Rectangle Tube 6061-T6-Extruded | 6061 | T6 | 1" | 1.5" | 0.125" |

| 1" x 2" x 0.125" Aluminum Rectangle Tube 6061-T6-Extruded | 6061 | T6 | 1" | 2" | 0.125" |

| 1" x 3" x 0.125" Aluminum Rectangle Tube 6061-T6-Extruded | 6061 | T6 | 1" | 3" | 0.125" |

| 1-1/2" x 3" x 0.125" Aluminum Rectangle Tube 6061-T6-Extruded | 6061 | T6 | 1-1/2" | 3" | 0.125" |

| 1-1/2" x 4" x 0.125" Aluminum Rectangle Tube 6061-T6-Extruded | 6061 | T6 | 1-1/2" | 4" | 0.125" |

| 2" x 3" x 0.125" Aluminum Rectangle Tube 6061-T6-Extruded | 6061 | T6 | 2" | 3" | 0.125" |

| 2" x 4" x 0.125" Aluminum Rectangle Tube 6061-T6-Extruded | 6061 | T6 | 2" | 4" | 0.125" |

| 2" x 6" x 0.125" Aluminum Rectangle Tube 6061-T6-Extruded | 6061 | T6 | 2" | 6" | 0.125" |

| 1" x 1.5" x 0.125" Aluminum Rectangle Tube 6061-T6-Extruded | 6061 | T6 | 1" | 1.5" | 0.125" |

| 1.5" x 3" x 0.125" Aluminum Rectangle Tube 6061-T6-Extruded | 6061 | T6 | 1.5" | 3" | 0.125" |

| 1.5" x 2" x 0.125" Aluminum Rectangle Tube 6061-T6-Extruded | 6061 | T6 | 1.5" | 2" | 0.125" |

| 1.5" x 4" x 0.125" Aluminum Rectangle Tube 6061-T6-Extruded | 6061 | T6 | 1.5" | 4" | 0.125" |

| 2" x 8" x 0.125" Aluminum Rectangle Tube 6061-T6-Extruded | 6061 | T6 | 2" | 8" | 0.125" |

| 2" x 4" x 0.1875" Aluminum Rectangle Tube 6061-T6-Extruded | 6061 | T6 | 2" | 4" | 0.1875" |

| 3" x 5" x 0.1875" Aluminum Rectangle Tube 6061-T6-Extruded | 6061 | T6 | 3" | 5" | 0.1875" |

| 2" x 3" x 0.188" Aluminum Rectangle Tube 6061-T6-Extruded | 6061 | T6 | 2" | 3" | 0.188" |

| 2" x 3" x 0.25" Aluminum Rectangle Tube 6061-T6-Extruded | 6061 | T6 | 2" | 3" | 0.25" |

| 2" x 4" x 0.25" Aluminum Rectangle Tube 6061-T6-Extruded | 6061 | T6 | 2" | 4" | 0.25" |

| 2" x 6" x 0.25" Aluminum Rectangle Tube 6061-T6-Extruded | 6061 | T6 | 2" | 6" | 0.25" |

| 3" x 5" x 0.25" Aluminum Rectangle Tube 6061-T6-Extruded | 6061 | T6 | 3" | 5" | 0.25" |

| 4" x 6" x 0.25" Aluminum Rectangle Tube 6061-T6-Extruded | 6061 | T6 | 4" | 6" | 0.25" |

| 4" x 8" x 0.25" Aluminum Rectangle Tube 6061-T6-Extruded | 6061 | T6 | 4" | 8" | 0.25" |

| 2" x 4" x 0.25" Aluminum Rectangle Tube 6061-T6-Extruded | 6061 | T6 | 2" | 4" | 0.25" |

| 3" x 4" x 0.25" Aluminum Rectangle Tube 6061-T6-Extruded | 6061 | T6 | 3" | 4" | 0.25" |

| 2" x 5" x 0.25" Aluminum Rectangle Tube 6061-T6-Extruded | 6061 | T6 | 2" | 5" | 0.25" |

| 3" x 8" x 0.25" Aluminum Rectangle Tube 6061-T6-Extruded | 6061 | T6 | 3" | 8" | 0.25" |

| 3" x 6" x 0.25" Aluminum Rectangle Tube 6061-T6-Extruded | 6061 | T6 | 3" | 6" | 0.25" |

| 6" x 8" x 0.375" Aluminum Rectangle Tube 6061-T6-Extruded | 6061 | T6 | 6" | 8" | 0.375" |

| 4" x 6" x 0.5" Aluminum Rectangle Tube 6061-T6-Extruded | 6061 | T6 | 4" | 6" | 0.5" |

Click to see all

Click to see all If the popular sizes above do not match your expected size, please contact us and we will quickly find the right size in stock.

Dimensional tolerances of 6061 rectangular aluminum tubes

Mastar's rectangular tubes have very strict tolerance requirements and follow the tolerance specifications of EN755.

Width and height tolerance

| Alloy-Temper(s) | Method | Spec. Height & Width, in. | Height & Width Tol. (at corners) (over(+)/under(-)) | Height & Width Tol. (not at corners) (over(+)/under(-)) |

| 6061-T6 | Extruded | 0.500 to 0.749 | +/- 0.012" | +/- 0.020" |

| 6061-T6 | Extruded | 0.750 to 0.999 | +/- 0.014" | +/- 0.020" |

| 6061-T6 | Extruded | 1.000 to 1.999 | +/- 0.018" | +/- 0.025" |

| 6061-T6 | Extruded | 2.000 to 3.999 | +/- 0.025" | +/- 0.035" |

| 6061-T6 | Extruded | 4.000 to 4.999 | +/- 0.035" | +/- 0.045" |

| 6061-T6 | Extruded | 5.000 to 5.999 | +/- 0.045" | +/- 0.055" |

| 6061-T6 | Extruded | 6.000 to 6.999 | +/- 0.055" | +/- 0.065" |

| 6061-T6 | Extruded | 7.000 to 7.999 | +/- 0.065" | +/- 0.075" |

| 6061-T6 | Extruded | 8.000 to 8.999 | +/- 0.075" | +/- 0.085" |

| 6061-T6 | Extruded | 9.000 to 9.999 | +/- 0.085" | +/- 0.095" |

| 6061-T6 | Extruded | 10.000 to 10.999 | +/- 0.095" | +/- 0.105" |

| 6061-T6 | Extruded | 11.000 to 12.999 | +/- 0.105" | +/- 0.115" |

Wall thickness tolerance reference

Alloy-TemperMethodWall(inch)Circumscribing Circle Dia. Under 5.000(Dims < 3" x 4") Wall tolerance Circumscribing Circle Dia.5.000 and over(Dims ≥ 3" x 4") Wall tolerance

| Alloy-Temper | Method | Wall(inch) | Circumscribing Circle Dia. Under 5.000(Dims < 3" x 4") Wall tolerance | Circumscribing Circle Dia.5.000 and over(Dims ≥ 3" x 4") Wall tolerance |

| 6061-T6 | Extruded | Under 0.047 | +/- 0.005" | +/- 0.008" |

| 6061-T6 | Extruded | 0.047 to 0.061 | +/- 0.006" | +/- 0.009" |

| 6061-T6 | Extruded | 0.062 to 0.124 | +/- 0.007" | +/- 0.010" |

| 6061-T6 | Extruded | 0.125 to 0.249 | +/- 0.008" | +/- 0.015" |

| 6061-T6 | Extruded | 0.250 to 0.374 | +/- 0.011" | +/- 0.020" |

| 6061-T6 | Extruded | 0.375 to 0.499 | +/- 0.014" | +/- 0.030" |

| 6061-T6 | Extruded | 0.500 to 0.749 | +/- 0.025" | +/- 0.040" |

| 6061-T6 | Extruded | 0.750 to 0.999 | +/- 0.035" | +/- 0.050" |

| 6061-T6 | Extruded | 1.000 to 1.499 | +/- 0.045" | +/- 0.060" |

| 6061-T6 | Extruded | 1.500 to 2.000 | ... | +/- 0.070" |

Why use 6061 rectangular tube?

- Mature technology: The production technology is mature, and it can be manufactured in large quantities at low cost.

- Stable structure: The plane design of 6061 rectangular tube makes it have higher bending and torsion resistance in the direction of force, which is suitable for frame and support structure.

- High space utilization: 6061 rectangular tube can better fit the plane structure, effectively save space, and is more flexible in narrow or complex installation environments.

- Easy to connect and install: The plane and right-angle design of 6061 rectangular tube makes it easier to weld and connect, especially suitable for installation needs that require a flat surface.

- Beautiful: In architectural and decorative applications, the rectangular tube has a simple and modern appearance and is more decorative. It is suitable for display racks, furniture and other occasions with high appearance requirements.

- Multi-directional bearing capacity: 6061 rectangular tube has good bearing capacity in different directions and can provide different strength support in horizontal and vertical directions.

- Strong deformation resistance: The rectangular tube has higher deformation resistance when the plane is compressed, and it is not easy to bend and deform under unidirectional pressure, which is suitable for compressed parts.

Applications of 6061 rectangular aluminum tube in different fields

- Building structures: 6061 rectangular tubes are widely used for building frames, window and door frames, and various guardrails. For enhanced corrosion resistance and surface finish, alloys like 6063 or 5083 rectangular tubes are also recommended.

- Mechanical manufacturing: Commonly used in equipment frames, brackets, and structural components. When higher strength is required, 6082 aluminum is a strong choice, while 2024 tubes are ideal for dynamic load-bearing parts.

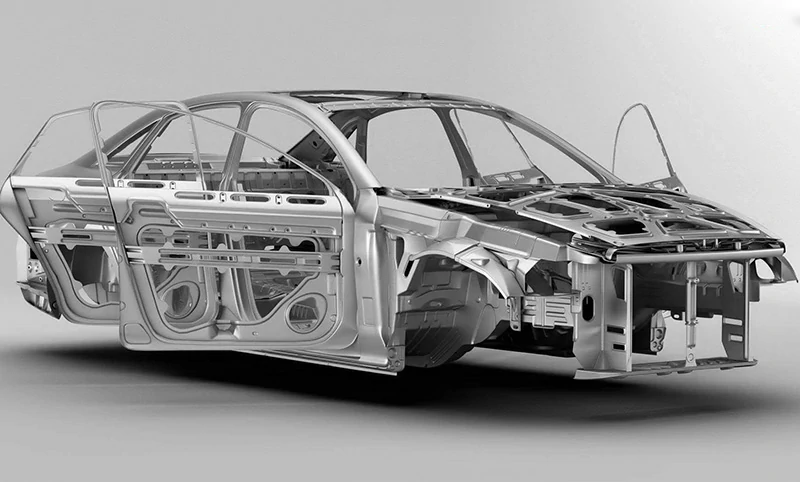

- Automotive industry: Applied in vehicle frames, battery housings, and lightweight structures. In addition to 6061, 5052 and 7005 aluminum tubes are often used where superior formability or impact resistance is needed.

- Furniture manufacturing: Used for lightweight and durable furniture frames, display racks, and similar applications. For better decorative surfaces, anodized 6061 or 6063 tubes are often preferred.

- Conveying equipment: 6061 rectangular tubes provide stable support for conveyor frames and structures. For applications demanding increased corrosion resistance or structural rigidity, 5456 or 5086 rectangular tubes offer reliable alternatives.

- Solar brackets: 6061 is widely used for solar PV mounting structures due to its strength and lightweight nature. Depending on load and environmental needs, it is often used in combination with 6005A or 6063 square/rectangular tubes.

Mechanical properties of 6061 rectangular aluminum tube

| Hardness, Brinell | 95HB |

| Tensile Strength, Ultimate | 310MPa |

| Tensile Strength, Yield | 276MPa |

| Notched Tensile Strength | 324MPa |

| Ultimate Bearing Strength | 607MPa |

| Bearing Yield Strength | 386Mpa |

| Elongation | 17% |

6061 rectangular aluminum tube vs 6063 rectangular aluminum tube

| Characteristic/Consideration | 6061 Rectangular Aluminum Tube | 6063 Rectangular Aluminum Tube | Selection Recommendation |

| Main Composition | Al-Mg-Si-Cu | Al-Mg-Si | Choose based on specific application |

| Strength | High | Moderate | Choose 6061 for high strength needs, 6063 for general strength needs |

| Ductility | Good | Excellent | Choose 6063 for better formability |

| Weldability | Very good | Excellent | Choose 6063 for frequent welding, both are suitable for general welding |

| Corrosion Resistance | Very good | Excellent | Choose 6063 for harsh environments, both are suitable for normal environments |

| Anodizing Effect | Good | Excellent | Choose 6063 for high-quality surface finishing |

| Machinability | Good | Excellent | Choose 6063 for complex machining, both are suitable for general machining |

| Thermal Conductivity | High | Moderate | Choose 6061 for better heat dissipation |

| Typical Applications | Structural parts, mechanical components | Construction, decoration | Choose 6061 for structural applications, 6063 for decorative applications |

| Cost | Higher | Lower | Choose 6063 for tighter budgets, 6061 for performance prioritization |

| Strength-to-Weight Ratio | High | Moderate | Choose 6061 for lightweight and high-strength needs |

| Fatigue Strength | High | Moderate | Choose 6061 for applications under cyclic loads |

| Surface Finish | Good | Excellent | Choose 6063 for applications with high appearance requirements |

| Hardness | High | Moderate | Choose 6061 for higher wear resistance |

Production process of 6061 rectangular aluminum tube

- Raw material preparation: Select and preheat high-quality 6061 aluminum alloy ingots to prepare for extrusion.

- Extrusion molding: The preheated aluminum material is extruded through a special rectangular die under high pressure to form the required cross-sectional shape.

- Cooling treatment: Rapidly cool the extruded profile to prevent cracking and deformation.

- Stretching and straightening: Slightly stretch the profile to eliminate internal stress and improve straightness and dimensional accuracy.

- Cutting processing: Cut the long profile into the required length to ensure smooth cuts.

- Heat treatment (T6): Improve material strength and hardness through solid solution, quenching and aging treatment.

- Surface treatment: Anodizing, electrophoretic coating or powder spraying are performed as required to improve corrosion resistance and aesthetics.

- Quality inspection: Dimensional, mechanical properties and surface quality inspections are carried out to ensure compliance with specifications.

- Packaging and storage: Properly packaged and stored in a suitable environment to prevent damage during transportation and storage.

What surface treatments can be done on Mastar's 6061 rectangular aluminum tubes?

Mastar's 6061 rectangular aluminum tubes can be anodized, powder coated, polished, sandblasted and other surface treatment processes, with any color to choose and strong customizability.

Mastar 6061 rectangular aluminum tube selection guide

Application requirements: Please inform us in detail about the specific application scenarios for purchasing 6061 rectangular aluminum tubes, including whether there are special strength requirements, environmental conditions (such as corrosive environments), etc., so that we can recommend the most suitable products for you.

Specifications and dimensions: Please provide the specific dimensions of the required aluminum tubes, including length, width, thickness, etc. We support customized specifications to ensure that the products fully meet the needs of your project.

Quantity requirements: Please specify your order quantity, which will help us provide you with a more accurate quotation and delivery cycle.

Surface treatment requirements: If you have special requirements for anodizing or other surface treatments, please let us know in advance and we will process according to your needs.

Delivery time: Please let us know your project schedule and delivery deadline, and we will try our best to arrange production and distribution to ensure delivery within the time you need.

Other special requirements: If there are any additional customization requirements (such as special packaging, logistics arrangements, etc.), please communicate with us in advance.

Quick response quotation: Based on the above points, we promise to respond to your inquiries quickly and provide competitive prices and clear quotations.

Click to collapse

Click to collapse