7005 aluminum round tube belongs to the Al-Zn-Mg-Cu series of alloys and is a forged aluminum alloy. 7005 aluminum is a heat-treatable high-strength alloy with excellent corrosion resistance and weldability. It has a high structural surface finish and is mainly used in load-bearing components for road and rail vehicles, rail transit aluminum extrusions, bicycle frames, tent poles, and more.

Equivalent names for 7005 aluminum alloy

| UNS | European standards | EN chemical designation |

| A97005 | EN AW-7005 | AlZn4,5Mg1,5Mn |

Mastar can provide different types of 7005 aluminum tubes, and customization is available for production processes, surface treatments, dimensions, and packaging. We also offer cutting, CNC machining, and other services to meet your customization needs.

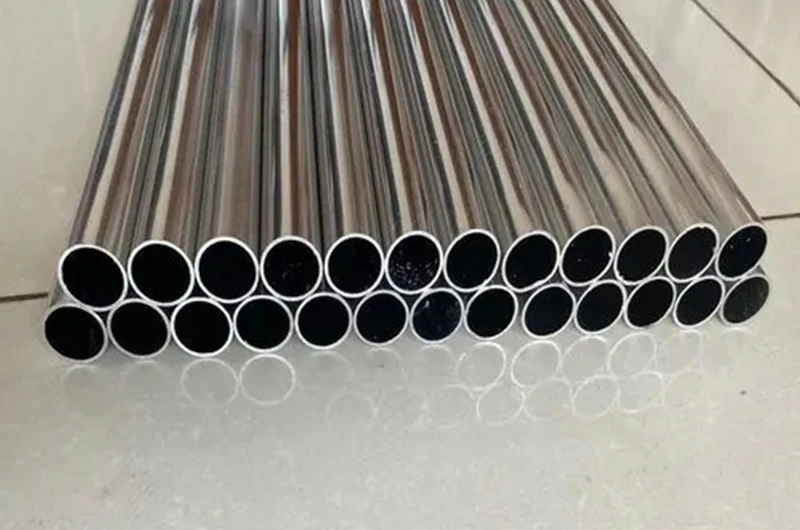

7005 extruded aluminum round tubing

Characteristics: High strength, lightweight, and excellent weldability.

Popular applications: Mainly used in bicycle frames.

Sizes: Diameter: 6-500 mm; wall thickness: 0.5-50 mm.

Overview of common frame tubes:

- 7005 round seat tube

- 7005 top tube

- 7005 down tube

- 7005 bicycle head tube

- 7005 rear upper fork tube

- 7005 rear lower fork tube

The table below shows the common sizes of 7005 aluminum tubes used for bicycle frames, where "/" represents reduced diameter and wall thickness parameters.

| Types | Diameter(mm) | Wall(mm) | length(mm) |

| 7005 round seat tube | 31.7 | 2.2/1.6 | 620 |

| 7005 round seat tube | 31.7 | 2.2/1.0/1.6 | 650 |

| 7005 round seat tube | 35 | 1.6/2 | 620 |

| 7005 round seat tube | 35 | 1.65 | 650 |

| 7005 round seat tube | 35 | 1.7/0.9/1.5 | 650 |

| 7005 round seat tube | 35 | 1.7/1.2/1.5 | 520 |

| 7005 round seat tube | 35 | 2.2/1.5 | 800 |

| 7005 round top tube | 35 | 1.4/1.1 | 600 |

| 7005 round top tube | 35 | 2.0/1.3/1.8 | 610 |

| 7005 round top tube | 36 | 1.3/0.9/1.3 | 620 |

| 7005 round top tube | 35 | 1.2/0.8/1.2 | 600 |

| 7005 round top tube | 38 | 1.6/1.2/1.6 | 660 |

| 7005 oval top tube | 42 x 26.5 | 1.4/1.1 | 600 |

| 7005 oval top tube | 41/31 | 1.3/0.9/1.3 | 620 |

| 7005 tapered top tube | 42.6/34 | 1.4/1.1 | 680 |

| 7005 round down tube | 38 | 1.6/1.2/1.6 | 660 |

| 7005 round down tube | 42 | 1.9/1.1/1.3 | 680 |

| 7005 round down tube | 42.6 | 1.5/1.2 | 670 |

| 7005 round down tube | 44 | 2/1.0/1.4 | 750 |

| 7005 round down tube | 44 | 1.2/0.9 | 670 |

| 7005 round head tube | 52/64 | 5 | 127 |

| 7005 round head tube | 50 | 3 | 200 |

7005 telescoping aluminum round tubing

Features: Flexible design allows for length adjustment as needed, providing convenience.

Main applications: Tent poles, trekking poles, selfie sticks.

Common sizes: Outer diameter 9-18 mm, wall thickness 0.2-2.0 mm.

The table below shows common sizes of 7005 telescoping aluminum tubes for tent poles:

| Outer tube diameter (mm) | Inner tube diameter (mm) | Wall (mm) | Telescoping length range (mm) | Applicable tent types |

| 18 | 16 | 1.2 - 1.8 | 600 - 1300 | Large camping tents, multifunctional tents |

| 20 | 18 | 1.2 - 2.0 | 700 - 1400 | Extra-large tents, military tents |

| 19 | 17 | 1.0 - 1.5 | 700 - 1200 | Multi-person tents, long-duration camping tents |

| 16.5 | 14.5 | 1.0 - 1.5 | 600 - 1100 | Medium to large tents |

| 15 | 13 | 0.8 - 1.2 | 500 - 1000 | Medium camping tents |

| 13.5 | 11.5 | 0.8 - 1.2 | 500 - 900 | 3-4 person tents |

| 12 | 10 | 0.8 - 1.2 | 400 - 800 | Small camping tents |

| 10 | 8 | 0.6 - 1.0 | 400 - 700 | Lightweight tents |

| 9 | 7 | 0.6 - 1.0 | 300 - 600 | Single-person tents, lightweight tents |

7005 cold drawn aluminum round tube

Features: High precision, smaller wall thickness tolerances, and smoother surfaces.

Main applications: High-end bicycle frames, precision structural components.

Size range: Diameter: 1-20 mm; wall thickness: 0.1-0.5 mm.

Tolerance range: ±0.3 mm.

The table below shows the sizes of 7005 cold drawn aluminum tubes:

| OD (mm) | Wall(mm) | ID (mm) |

| 3 | 0.1 | 2.8 |

| 3 | 0.2 | 2.6 |

| 4 | 0.3 | 3.4 |

| 4 | 0.4 | 3.2 |

| 4 | 0.5 | 3 |

| 6 | 0.2 | 5.6 |

| 6 | 0.4 | 5.2 |

| 6 | 0.5 | 5 |

| 7 | 0.3 | 6.4 |

| 8 | 0.1 | 7.8 |

| 8 | 0.2 | 7.6 |

| 8 | 0.5 | 7 |

| 9 | 0.1 | 8.8 |

| 9 | 0.2 | 8.6 |

| 9 | 0.5 | 8 |

| 10 | 0.4 | 9.2 |

| 10 | 0.5 | 9 |

| 12 | 0.4 | 11.2 |

| 12 | 0.5 | 11 |

| 14 | 0.5 | 13 |

| 16 | 0.5 | 15 |

| 20 | 0.5 | 19 |

Mechanical properties of 7005 aluminum round tube

| Temper | Hardness, Brinell | Tensile Strength, | Yield Strength, | Elongation |

| O | 53HB | 195MPa | 80MPa | 20% |

| T5 | 105HB | 400Mpa | 350MPa | 15% |

| T53 | 105HB | 390MPa | 345Mpa | 15% |

| T6 | 94HB | 350MPa | 290MPa | 13% |

Production process of 7005 aluminum round tube

- Casting: Pour molten 7005 aluminum alloy into molds to cast preliminary aluminum tube billets.

- Extrusion: At appropriate temperatures, extrude the 7005 aluminum billets into the desired aluminum tube profiles using an extrusion press.

- Aging treatment: Perform artificial aging treatment (T5 or T6 temper) on the 7005 aluminum tubes to improve their strength and hardness.

- Cooling and annealing: Slowly cool the 7005 aluminum tubes in the cooling area and perform annealing treatment as necessary to improve their machinability.

- Cutting and machining: Cut the 7005 aluminum tubes to specified lengths and carry out further machining.

- Surface treatment: Apply surface treatments, such as anodizing, to the 7005 aluminum tubes to enhance their corrosion resistance and appearance.

- Inspection and quality control: Conduct inspections on dimensions, strength, and hardness of the 7005 aluminum tubes to ensure compliance with relevant standards and customer requirements.

Why choose Mastar?

- Free samples are provided, and orders are placed after the samples have passed the test to ensure that the products meet the requirements.

- Sizes, specifications, and surface treatments can be customized free of charge to perfectly meet your customized needs.

- Various quality inspection reports are provided as required, and the product quality is guaranteed, so you can buy with confidence.

- If you don't know what alloy the product is suitable for, we can provide a full set of professional solutions.

- The quotation response is fast and professional, and the delivery is fast.