6005A Aluminum Tube belongs to Al-Mg_Si alloy, which is a medium strength alloy. 6005A Aluminum alloy is a heat treatable alloy with excellent corrosion resistance. It is commonly used in transportation and structural engineering applications.

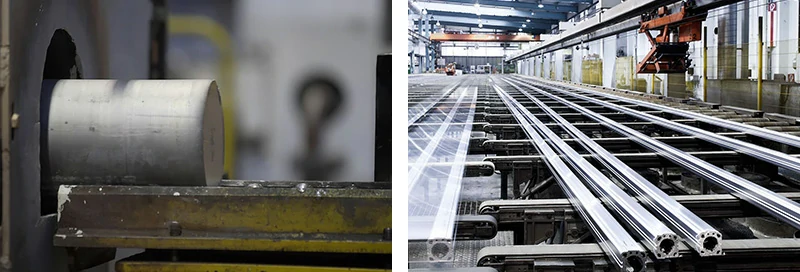

6005A aluminum alloy is difficult to produce thin-walled or complex extrusions, but it still has better extrusion performance than 6082 aluminum alloy. Mastar's 6005A aluminum tubes produced by advanced extrusion equipment have very good bending properties and are stronger than 6063 aluminum tubes.

Equivalent grades of 6005A aluminum alloy

| EN 573-3 | UNS | ISO 209 | DIN 1725-1 | BS |

| EN AW-6005A | А96005A | 6005A | AlMgSi0.7 | H10 |

Mastar 6005A aluminum tube standard specification and certification

Specification:ASTM B211, ASTM B 241, EN 755-2

Certification:NADCAP, ISO, RoHS, REACH

Popular 6005A aluminum tube products

6005A aluminum round tube

6005A aluminum round tube- Outer diameter: 10mm – 300mm

- Wall thickness: 5mm - 25mm

- Applications: passenger vehicle frames, furniture, stairs

- View best-selling size chart.

6005A aluminum square tube

6005A aluminum square tube- Temper: T6

- Width: 20 - 200mm

- Wall thickness: 5 - 15mm

- Applications: structural applications, railings, building frames.

6005A telescopic aluminum tube

6005A telescopic aluminum tube- Temper: T6

- Shape: Round, Square

- Applications: measuring poles, aerial work poles, display racks, selfie sticks.

Why use 6005A aluminum tube?

Corrosion resistance: This alloy has good corrosion resistance, which is one of its most notable features. The addition of silicon and magnesium greatly contributes to this property. It is commonly used in marine applications due to its ability to withstand saltwater exposure.

Excellent welding performance: 6005A has excellent weldability. It is recommended to use 4043 welding wire unless connecting to one of the 7XXX series, in which case 5356 welding wire is suggested as an alternative.

Good machining performance: It has good extrusion properties, but it performs poorly in producing thin-walled or complex shapes.

Typical applications of 6005A aluminum tube

- Platforms, ladders, structures

- Marine applications, truck trailers, automotive, bus, and railway components

- Industrial towers, pipelines, and platforms

- Piping in furniture products

Popular sizes of 6005A aluminum round tube

| Alloy Temper | OD (mm) | OD (in) | Wall (mm) | Wall (in) |

| 6005A-T6 aluminum round tube - Extruded | 10mm | 0.39" | 5mm | 0.2" |

| 6005A-T6 aluminum round tube - Extruded | 15mm | 0.59" | 5mm | 0.2" |

| 6005A-T6 aluminum round tube - Extruded | 20mm | 0.79" | 5mm | 0.2" |

| 6005A-T6 aluminum round tube - Extruded | 25mm | 0.98" | 5mm | 0.2" |

| 6005A-T6 aluminum round tube - Extruded | 30mm | 1.18" | 5mm | 0.2" |

| 6005A-T6 aluminum round tube - Extruded | 50mm | 1.97" | 10mm | 0.39" |

| 6005A-T6 aluminum round tube - Extruded | 75mm | 2.95" | 10mm | 0.39" |

| 6005A-T6 aluminum round tube - Extruded | 100mm | 3.94" | 10mm | 0.39" |

| 6005A-T6 aluminum round tube - Extruded | 150mm | 5.91" | 15mm | 0.59" |

| 6005A-T6 aluminum round tube - Extruded | 200mm | 7.87" | 20mm | 0.79" |

| 6005A-T6 aluminum round tube - Extruded | 250mm | 9.84" | 25mm | 0.98" |

| 6005A-T6 aluminum round tube - Extruded | 300mm | 11.81" | 25mm | 0.98" |

Best-selling sizes of 6005A telescopic aluminum tube

| Product | OD(inch) | ID(inch) |

| 6005A-T6 aluminum round telescoping tube | 0.5" | 0.11" |

| 6005A-T6 aluminum round telescoping tube | 0.55" | 0.325" |

| 6005A-T6 aluminum round telescoping tube | 0.75" | 0.11" |

| 6005A-T6 aluminum round telescoping tube | 0.8" | 0.58" |

| 6005A-T6 aluminum round telescoping tube | 1" | 0.11" |

| 6005A-T6 aluminum round telescoping tube | 1.05" | 0.83" |

| 6005A-T6 aluminum round telescoping tube | 1.25" | 0.11" |

| 6005A-T6 aluminum round telescoping tube | 1.3" | 1.08" |

| 6005A-T6 aluminum round telescoping tube | 1.5" | 0.11" |

| 6005A-T6 aluminum round telescoping tube | 1.75" | 0.11" |

| 6005A-T6 aluminum round telescoping tube | 2" | 0.11" |

Strict tolerance specifications for 6005A aluminum tube

All Mastar's 6005 aluminum tube tolerances strictly adhere to the EN 754-7 standard, ensuring manufacturing precision.

Tolerances on thickness

| Thickness | Tolerances in % |

| 0.5 - 1 mm | ± 10 |

| 1 -2 mm | ± 9 |

| 2 -3 mm | ± 8 |

| >3 mm | ± 7 |

Tolerances on outside diameter

| Outside diameter in mm | tolerance % |

| 3 - 8 | ± 0.09 |

| 8 - 18 | ± 0.09 |

| 18 - 30 | ± 0.11 |

| 30 - 50 | ± 0.13 |

| 50 - 80 | ± 0.15 |

| 80 - 120 | ± 0.20 |

| 120 - 180 | ± 0.40 |

Tolerances on inside diameter

| Inside diameter in mm | tolerance % |

| 3 - 8 | ± 0.15 |

| 8 - 18 | ± 0.09 |

| 18 - 30 | ± 0.11 |

| 30 - 50 | ± 0.13 |

| 50 - 80 | ± 0.15 |

| 80 - 120 | ± 0.20 |

| 120 - 180 | ± 0.40 |

Characteristics of 6005A aluminum tube

- Density: 2.71 g/cm³ or 169 lb/ft³.

- Electrical conductivity: 47 to 50% IACS.

- Young's modulus: 70 GPa or 10 Msi.

- Thermal conductivity: 180 to 190 W/mK.

- Thermal expansion: 23.3 μm/mK.

Chemical composition of 6005A aluminum tube

| Elements | % Present |

| Manganese (Mn) | 0.00 - 0.50 |

| Iron (Fe) | 0.00 - 0.35 |

| Magnesium (Mg) | 0.40 - 0.70 |

| Silicon (Si) | 0.50 - 0.90 |

| Zinc (Zn) | 0.00 - 0.20 |

| Titanium (Ti) | 0.00 - 0.10 |

| Chromium (Cr) | 0.00 - 0.30 |

| Copper (Cu) | 0.00 - 0.30 |

| Manganese + Chromium (Mn+Cr) | 0.12 - 0.50 |

| Other (Each) | 0.00 - 0.05 |

| Others (Total) | 0.00 - 0.15 |

| Aluminium (Al) | Remainder |

Chemical Composition According to BS EN 573-3 standard specification, the composition of 6005A aluminium is notable for containing relatively high amounts of silicon (Si) and magnesium (Mg). Silicon is used to increase strength, but at the expense of ductility. It also lowers the melting temperature and increases the fluidity of the alloy. Magnesium increases hardenability through heat treatment and strain hardening mechanisms. It also increases susceptibility to intergranular corrosion. Manganese and chromium have an anti-crystallisation effect.

Mechanical properties of 6005A aluminum tube

| Wall thickness | Hardness, Brinell | Tensile Strength, Ultimate | Tensile Strength, Yield | Elongation |

| ≤5mm | 90HB | 270MPa | 225MPa | 8% |

| 5mm - 10mm | 85HB | 260Mpa | 215MPa | 8% |

Comparison of 6005 aluminum vs. 6005A aluminum alloy

Chemical composition

6005 aluminum alloy: With a higher silicon content, it has a lower melting point and enhanced extrusion performance. This high silicon content allows 6005 aluminum to be easily formed during production, particularly for complex profiles manufactured through extrusion processes.

6005A aluminum alloy: Compared to 6005, 6005A contains more chromium and manganese. The increase in chromium reduces the risk of stress corrosion cracking while improving the material's toughness. The addition of manganese further enhances its extrudability and strength, making 6005A aluminum superior in mechanical properties.

Mechanical properties

6005 aluminum: It has good extrudability, suitable for manufacturing medium-strength, simple structural components and profiles. While the increased silicon content aids extrusion, it does not significantly enhance strength or toughness, making 6005 aluminum suitable for applications with lower strength requirements.

6005A aluminum: The addition of manganese and chromium improves strength and toughness, giving it an advantage in certain high-strength applications. Its enhanced strength allows it to perform better under higher mechanical loads.

Corrosion resistance

6005 aluminum: It has good corrosion resistance, suitable for outdoor or corrosive environments, but its resistance to stress corrosion is slightly inferior to that of 6005A.

6005A aluminum: Due to the addition of chromium, 6005A exhibits better resistance to stress corrosion cracking, making it more durable in harsher environments. This results in greater stability over long-term use..

Welding performance

6005 aluminum and 6005A aluminum: Both have good welding performance and are easy to weld using standard operations, making them suitable for applications like building frames and machinery that require welding. However, the heat generated during welding can reduce the strength of both aluminum alloys, so this should be considered in the design process.

Bending performance

Both exhibit excellent bending performance, providing flexible shapes and structures for various applications. However, they are not suitable for applications that frequently experience overload or impacts, as this could lead to structural fatigue or damage.

Extrusion and complexity of shapes

6005 aluminum: While the high silicon content helps improve extrusion performance, it still faces challenges in producing thin-walled and complex shapes.

6005A aluminum: The addition of extra manganese enhances the extrusion performance of 6005A, but it also performs poorly in producing thin-walled, complex profiles.

Surface treatment and anodizing

6005 aluminum and 6005A aluminum: Both are well-suited for anodizing treatments, such as dyeing, hard coating, and coloring. Anodizing enhances their corrosion resistance and improves the aesthetic appeal of the surface treatment. In contrast, un-anodized aluminum alloys are more susceptible to environmental contaminants, and prolonged exposure may lead to corrosion.

What services can Mastar provide for you?

As a professional supplier of 6005A aluminum tubes, Mastar is committed to a customer-centric approach, continuously providing high-quality products. We can offer you the following services:

Customized production: Provide different specifications and sizes of 6005A aluminum tubes based on customer requirements, along with various surface treatment services to meet the specific needs of different applications.

Fast delivery: With a rich inventory, we ensure timely delivery to meet your production schedule.

Tailored solutions: Offer personalized solutions for different application areas and project requirements to help customers achieve optimal performance.

Long-term cooperation discounts: Provide preferential pricing and flexible payment options for long-term partners, reducing procurement costs and enhancing competitiveness.

Market trend consultation: We regularly provide updates on the latest market dynamics and technological trends in the aluminum industry, helping customers stay informed and optimize procurement decisions.