2A14 is a typical Al-Cu-Mg-Si aluminum alloy, characterized by exceptionally high strength, excellent corrosion resistance, and good heat-treatable strengthening capacity. It is a crucial material in the aerospace, automotive, and high-strength mechanical component manufacturing industries.

Compared to other aluminum alloys, 2A14 has higher copper and magnesium content, giving it a significant advantage in high-load, high-stress environments. Additionally, 2A14 aluminum tubing offers excellent machinability, meeting the manufacturing requirements for complex structural components.

Click to view the 2A14 Aluminum Tube Product Guide.

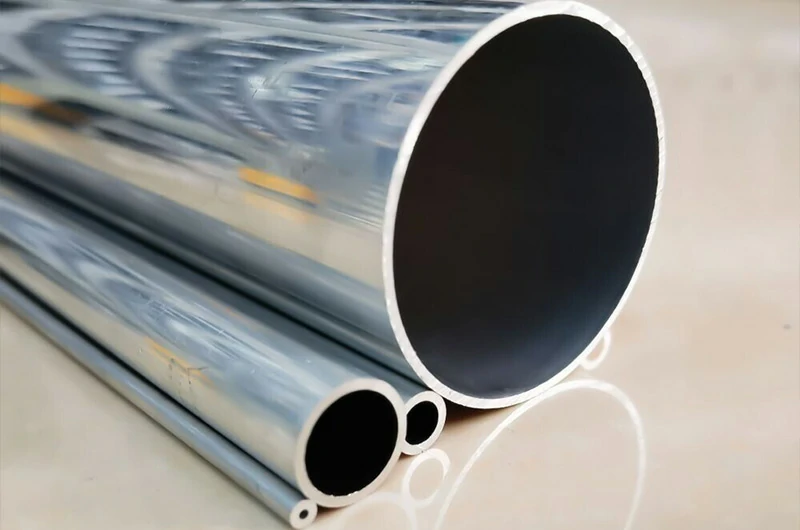

Popular Products of 2A14 Aluminum Tube

2A14 Seamless Aluminum Tube

2A14 Seamless Aluminum Tube- The 2A14 seamless aluminum tube, made via reverse extrusion, features uniform wall thickness and high compressive strength. Its seamless design minimizes weld defects, ideal for high-reliability aerospace applications.

- Click to find more seamless tube in MASTAR

2A14 Extruded Aluminum Tube

2A14 Extruded Aluminum Tube- The 2A14 extruded aluminum tube, made with high-precision extrusion, offers excellent surface quality, consistent mechanical properties, and stability. It is ideal for aerospace frameworks and automotive load-bearing structures.

2A14 Aluminum Forged Pipe

2A14 Aluminum Forged Pipe- The 2A14 forged aluminum pipe has high strength and fatigue resistance, ideal for high-load aerospace components, truck suspensions, and high-stress parts. Forging enhances internal consistency and structural performance.

2A14 Large Diameter Aluminum Tube

2A14 Large Diameter Aluminum Tube- The 2A14 large diameter aluminum tube, made via vertical extrusion, is ideal for high load-bearing applications like large frames, bridge structures, and heavy machinery. It ensures excellent mechanical support and stability under heavy loads.

2A14 Aluminum Round Tube

2A14 Aluminum Round Tube- Outer Diameter: 8-630mm

- The 2A14 aluminum round tube boasts high strength and good rigidity, widely used in high-load structures such as aerospace components, automotive chassis, and mechanical equipment.

- Click to find more round tube in MASTAR

2A14 Aluminium Square Tube

2A14 Aluminium Square Tube- Dimensions: 88mm - 350*350mm

- The 2A14 aluminum square tube, with its unique square cross-section, is popular in construction and machinery manufacturing. Its high strength and durability make it ideal for high-stress environments, providing excellent bending support.

- Click to find more square tube in MASTAR

2A14 Aluminum Oval Tube

2A14 Aluminum Oval Tube- Dimensions: 18*12mm - 200*300mm

- The 2A14 aluminum oval tube, known for its distinctive shape, is used in aesthetic and structural applications like architectural decor and specialized equipment. It offers good bending resistance and design flexibility.

Mastar Metal - Premium Aluminum Tube Supplier

- Competitive Pricing: Supporting both retail and bulk purchases for metal distributors, we offer discounts and rebate policies for B2B clients. Pricing is transparent, and we ensure a price advantage for tubes of the same quality.

- Timely Delivery: With tens of thousands of tons in inventory, standard sizes can be matched to stock for quick shipment. Advanced equipment and a professional team shorten delivery times, providing efficient logistics for on-time delivery.

- Premium Products: Using high-quality aluminum billets produced through reverse extrusion processes, complemented by excellent heat treatment techniques, we optimize product strength and ductility, ensuring uniform cooling and annealing for high tensile strength and superior performance.

- Comprehensive Quality Inspection: We strictly enforce multiple inspection procedures, including tensile strength, elongation performance, ultrasonic testing, and metallographic testing to ensure that aluminum bars meet AMS, EN, NADCAP, and other certification standards.

- Customer Service: Offering comprehensive after-sales service to address customer concerns, our experienced technical team provides professional consultation and support, establishing a robust customer service system for a superior service experience.

Core Advantages of 2A14 Aluminum Tube

1.High Strength and Excellent Thermal Strength: Compared to 2A50, 2A14 has a higher copper content, which enhances its strength and thermal strength. This feature makes 2A14 aluminum tube particularly suitable for load-bearing structural components, such as aircraft frames and suspension systems.

2.Excellent Machinability: The unique composition of the aluminum alloy gives 2A14 good machinability, making it ideal for processing, especially in the production of complex geometric parts.

3.Good Weldability: 2A14 aluminum tube performs well in resistance welding, spot welding, and seam welding. While its performance in arc welding and gas welding is relatively weaker, specialized processes can effectively overcome this limitation.

4.Corrosion Resistance: After artificial aging treatment, the risk of intergranular corrosion and stress corrosion cracking in 2A14 aluminum alloy is reduced, broadening its application in highly corrosive environments.

Application Fields for 2A14 Aluminum Bar

Aerospace Industry

2A14 aluminum tube is widely used in the aerospace industry for its high strength and excellent corrosion resistance, particularly in multi-stage rocket fuel tanks and aircraft structural components. These applications require materials that can maintain outstanding performance under high loads and complex stresses. The 2A14 T6 aluminum tube is especially common for critical structural parts.

To support various aerospace-grade demands, Mastar also offers 2A12 aluminum tube for balanced strength and 7075 aluminum tube for superior fatigue resistance — all available in custom forms.

Automotive Industry

In the automotive industry, 2A14 aluminum tube is commonly used in truck suspension systems and chassis components. Its high strength and lightweight properties effectively reduce vehicle weight, improving fuel efficiency while maintaining good performance. The 2A14 T4 aluminum tube's excellent toughness makes it ideal for impact-absorbing suspension systems.

For lightweight chassis or corrosion-prone parts, we also supply 6061 and 7005 aluminum tubes— ensuring alloy flexibility across your automotive project.

Construction Engineering

2A14 aluminum tube is widely used in construction and bridge building due to its high strength and corrosion resistance, especially for providing reliable support in heavy-load and harsh environments. Its lightweight nature effectively reduces structural weight while maintaining stability and durability.

From structural beams to decorative facades, Mastar delivers 6063 and 6082 aluminum tubes to meet full-spectrum architectural needs.

Heavy Machinery and Industrial Equipment

2A14 aluminum tube also plays a key role in heavy machinery and industrial equipment, particularly in environments demanding high strength and durability. 2A14 aluminum tube in T6 temper is well-suited for frames and structural components in heavy equipment, ensuring stability under high-stress conditions.

Looking for better machinability or pressure resistance? Mastar also supplies 2011 and 6262 tubes with tailored processing options.

Product Guide of 2A14 aluminum tube

Chemical composition of 2A14 aluminum tube

| Element | 2A14 |

| Si | 0.16-1.2 |

| Fe | 0.70 |

| Cu | 3.9-4.8 |

| Mn | 0.4-1.0 |

| Mg | 0.4-0.8 |

| Cr | - |

| Ni | 0.10 |

| Zn | 0.30 |

| Ti | 0.15 |

| Zr | - |

| Others (Each) | 0.05 |

| Others (Total) | 0.15 |

| Al | Rem |

Physical properties of 2A14 aluminum tube

| Properties | Value |

| Density | 2.68 g/cm³ |

Mechanical properties of 2A14 aluminum tube

| Properties | Value |

| Tensile strength Rm/MPa | 430 |

| Yield strength Rp0.2/MPa | 350 |

| Elongation | 6% |

Why is 2A14 Aluminum Tube Used for Rocket Fuel Tanks?

2A14 aluminum tube is well-suited for rocket fuel tanks due to its high strength, good corrosion resistance, lightweight nature, and excellent machinability. These qualities enable 2A14 aluminum tube to maintain stable and reliable performance under high-temperature, high-pressure, and complex stress conditions, meeting the stringent requirements of rocket launches.

2A14 vs. 2014 Aluminum Alloys

- Strength: The strength of 2A14 aluminum alloy is generally higher than that of 2014, especially in T6 temper, where 2A14 exhibits notably greater tensile strength. While 2014 aluminum also has high strength, the higher copper and magnesium content in 2A14 makes it superior for extreme applications.

- Corrosion Resistance: 2014 aluminum alloy offers better corrosion resistance overall. However, with artificial aging treatment, 2A14 can effectively mitigate intergranular corrosion, making it suitable for high-demand structural components.

- Formability and Heat Treatment: 2014 aluminum alloy, with added silicon, manganese, and magnesium, has good formability, making it ideal for applications needing formability and toughness, particularly in T4 temper. Conversely, 2A14 in T4 and T6 tempers better meets high-strength and heat-resistant application requirements, suitable for more demanding industrial and aerospace applications.

- Application Fields: 2014 aluminum alloy is primarily used in mechanical components, such as wheels and truck parts, due to its good machinability and formability. In contrast, 2A14 aluminum alloy, with its higher strength and better thermal strength, is suitable for high-strength critical components in aerospace and rocket fuel tanks.