6262 Aluminum is designed for operations that require extensive machining. It contains lead and bismuth to aid in chip generation and breaking, as well as partially lubricate cutting tools. 6262 is generally considered to have good strength, corrosion resistance, and surface finish. Finished parts can be polished to a high level. It is commonly used for camera parts, couplings, marine fittings, decorative hardware, hinge pins, knobs, nuts, tubing fittings, appliance fittings, valves, and valve parts.

MASTAR 6262 aluminum tube product introduction

Stock product types: drawn seamless tubes, extruded tubes, forged tubes, t-slot hollow extrusions

Schedule: SCH20, SCH30, SCH40, STD, SCH80, XS, SCH60, SCH80, SCH120, SCH140, SCH160, XXS

Length: Can be cut to any length.

Surface treatment: mill finish, anodized, bright, black, polished …

Aluminum tube ends: flat end, bevel end, threaded end

6262 aluminum equivalent names: UNS A96262, ISO AlMg1SiPb, AA6262, Al6262

MASTAR 6262 aluminum tube hot selling products

6262 T6 aluminum tube

6262 T6 aluminum tube- The T6 state is solution treated and artificially aged, giving the aluminum tube high strength and good corrosion resistance, making it very suitable for machining, structural parts and occasions requiring higher hardness.

6262 T9 aluminum tube

6262 T9 aluminum tube- T9 aluminum tubes are solution treated and age hardened to provide excellent fatigue and wear resistance for structural parts subject to high dynamic loads.

6262 T651 T6511 al tube

6262 T651 T6511 al tube- The T651 state eliminates internal stress through stretching, ensuring dimensional stability and high strength, and is suitable for structures with high precision requirements, such as precision mechanical parts.Similar to T651, T6511 is solution treated, stress relieved and aged and is primarily used for extruded shapes where shape is a requirement.

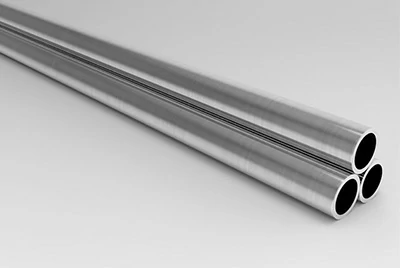

6262 drawn seamless

6262 drawn seamless- The seamless drawing process ensures the high strength and uniform mechanical properties of the aluminum tube. It is often used in piping systems for fluid transportation and high-pressure environments, and has good pressure resistance and corrosion resistance.

6262 extruded tube

6262 extruded tube- Extruded aluminum tubes have excellent plasticity and structural integrity, are suitable for making complex cross-sectional shapes, and are widely used in construction, the automotive industry, and frame structures.

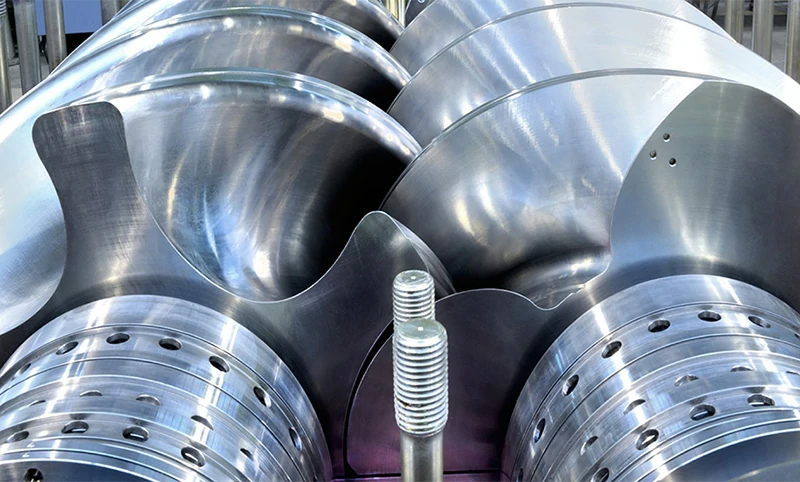

6262 forged pipe

6262 forged pipe- The forging process enhances the density and impact resistance of aluminum, making it suitable for applications requiring extremely high strength and durability, such as aerospace and military equipment.

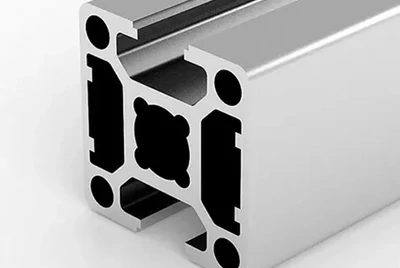

6262 T-slot hollow extrusion profile

6262 T-slot hollow extrusion profile- The 6262 T-slot hollow extrusion is an aluminum profile designed for frames and mechanical structures. It combines strength, corrosion resistance, and lead-enhanced machinability for easy chip breaking and a smooth surface finish, making it ideal for precision and flexible assembly.

6262 aluminum tube chemical composition

| Element | Component |

| Aluminum (Al) | 94.7 to 97.8 |

| Magnesium (Mg) | 0.8 to 1.2 |

| Silicon (Si) | 0.4 to 0.8 |

| Lead (Pb) | 0.4 to 0.7 |

| Bismuth (Bi) | 0.4 to 0.7 |

| Iron (Fe) | 0 to 0.7 |

| Copper (Cu) | 0.15 to 0.4 |

| Zinc (Zn) | 0 to 0.25 |

| Chromium (Cr) | 0.040 to 0.14 |

| Manganese (Mn) | 0 to 0.15 |

| Titanium (Ti) | 0 to 0.15 |

| Residuals | 0 to 0.15 |

6262 aluminum tube mechanical properties reference table

| Mechanical Properties | Metric | English |

| Hardness, Brinell | 103 | 103 |

| Hardness, Knoop | 129 | 129 |

| Hardness, Rockwell A | 42 | 42 |

| Hardness, Rockwell B | 65 | 65 |

| Hardness, Vickers | 116 | 116 |

| Tensile Strength, Ultimate | >= 310 MPa | >= 45000 psi |

| Tensile Strength, Yield | >= 296 MPa | >= 42900 psi |

| Elongation at Break | 12 % | 12 % |

| Modulus of Elasticity | 69.0 GPa | 10000 ksi |

| Poissons Ratio | 0.33 | 0.33 |

| Machinability | 70 % | 70 % |

| Shear Modulus | 26.0 GPa | 3770 ksi |

| Shear Strength | 185 MPa | 26800 psi |

6262 aluminum tube thermal performance reference table

| Thermal Properties | Metric | English |

| CTE, linear | 23.4 µm/m-°C @Temperature 20.0 - 100 °C | 13.0 µin/in-°F @Temperature 68.0 - 212 °F |

| 25.0 µm/m-°C @Temperature 20.0 - 300 °C | 13.9 µin/in-°F @Temperature 68.0 - 572 °F | |

| Specific Heat Capacity | 0.890 J/g-°C | 0.213 BTU/ lb- °F |

| Thermal Conductivity | 170 W/m-K | 1180 BTU-in/hr-ft²-°F |

| Melting Point | 582 - 651.7 °C | 1080 - 1205 °F |

| Solidus | 582 °C | 1080 °F |

| Liquidus | 651.7 °C | 1205 °F |

| Processing Properties | Metric | English |

| Annealing Temperature | 416 °C | 780 °F |

| Solution Temperature | 538 °C | 1000 °F |

| Aging Temperature | 171 °C | 340 °F |

MASTAR 6262 aluminum tube properties

- Easy to process: With excellent machinability, it can be effortlessly molded into complex shapes, allowing for precise customization and manufacturing.

- Thermal Stability: It exhibits minimal thermal expansion and contraction, ensuring dimensional stability even in fluctuating temperature environments, providing reliability and long life.

- Lightweight yet strong: Round bars offer an optimal balance of strength and lightweight properties, making them suitable for applications where weight reduction and structural integrity are critical.

- Corrosion Resistance: Alloy 6262 is one of the most resistant alloys to atmospheric and seawater corrosion. However, an important consideration is that two metals or alloys with different corrosion potentials can cause galvanic corrosion.

- Finishing: Enhanced with its resistance to corrosion and wear, the alloy has good finishing characteristics and readily accepts all types of anodic coatings (clear, clear and dye, hard coat, etc.).

- Joining : The joining characteristics of 6262 alloy are improved over 2011 alloy, although not as good as those of 6061 alloy. 6262 alloy welds readily by all gas, arc, and resistance methods and can also be brazed. Since it is a heat treatable alloy, its strength in the -T6 condition will be reduced by the heat generated by welding or brazing. The selection of a suitable filler alloy will depend on the weld characteristics required.

MASTAR 6262 aluminum tube cooperation areas

- Car and Truck Brake Parts

- Hydraulic valve block

- Air conditioning parts

- Manifold

- Electrical and cable components

- Screw machine products

- Ship accessories

- Oil pipeline accessories

- Hardware and fasteners, etc.

Why MASTAR is the preferred supplier of 6262 aluminum tube

- Fast Delivery: We have abundant inventory to ensure fast shipment of any product, saving time for your project.

- Customized service: MASTAR can provide customized service according to customer needs. You only need to inform the length, quantity, surface finish, cutting, bending, color coating, end use and other special requirements.

- Competitive Price: Our products are priced competitively and we offer reasonable discounts for large quantities, giving you better prices and quality service.

- After-sales support: We provide fast after-sales support to ensure that you get timely help and support when using our products.