2014 Aluminum is a high strength alloy containing 4 to 5% copper. Finished parts often require a protective coating to prevent corrosion. Once the alloy has been fully heat treated, cold formability is limited due to weldability. MASTAR stocks 2014A aluminum tubes in various sizes and conditions.

MASTAR 2014 aluminum tube product introduction

Stock product types: 2014 aluminum round tube; 2014 aluminum square tube; 2014 rectangular tube; 2014 forged tube

Schedule: SCH20, SCH30, SCH40, STD, SCH80, XS, SCH60, SCH80, SCH120, SCH140, SCH160, XXS

Length: Can be cut to any length.

Surface treatment: mill finish, anodized, bright, black, polished …

Aluminum tube ends: flat end, bevel end, threaded end

2014 Aluminum Equivalent Names

| 2014 Aluminum Equivalent Names | ||||||||

| UNS | WERKSTOFF NR. | European Standard | BS (OLD) | ISO | USA (AA) | GERMANY (DIN) | IS | Canadian |

| A92014 | 3.1255 | EN AW-2014 | HE15 | AlCu4SiMg | 2014 | AlCuSiMn | 24345 | B26S |

2014 aluminum round tube

With high strength and uniform load-bearing capacity, it is suitable for applications with high loads and pressure resistance, ensuring the long-term durability of the aluminum tube. Click to find more aluminum round tube in Mastar.

- Size range: 1-10

- Wall thickness range: 0.125-0.75

| MASTAR 2014 Aluminum Round Tube Hot Selling Product Size | |||

| Outer diameter | Wall thickness | ||

| Inch | Metric | Inch | Metric |

| 1/4" | 6.35mm | 0.035" | 0.889mm |

| 3/8" | 9.525mm | 0.049" | 1.245mm |

| 1/2" | 12.7mm | 0.065" | 1.651mm |

| 3/4" | 19.05mm | 0.083" | 2.108mm |

| 1 '' | 25.4mm | 0.125 inch | 3.175mm |

2014 aluminum alloy forged round tube

Forged aluminum tubes are also available in other high-strength grades like 7075 aluminum tube, which delivers superior tensile properties and is often used in aerospace, defense, and precision components under extreme stress.

- Outer diameter: 200-1000mm

- Wall thickness : 20-100mm

- The forged tube improves the tightness of the internal structure through the forging process, providing excellent strength and fatigue resistance.

- It is widely used in industries such as petroleum, chemical industry, machinery, construction, nuclear power, aerospace and transportation to meet the needs of high strength and high load.

2014 aluminum square tube

The square design provides excellent bending strength and stability, suitable for frames and structural members that are subjected to uniform pressure and require high-strength support. Click to find more square tube in Mastar.

- Size range: 1-8

- Wall thickness range: 0.125-0.5

2014 aluminum rectangular tube/flat tube

Rectangular tubes (including rounded or oval shapes) combine high strength with multi-directional load-bearing capacity, suitable for applications requiring enhanced structural stability and space optimization. Click to find more rectangular tube in Mastar.

- Size range: 1*2-8*12

- Wall thickness range: 0.125-0.5

In structural and load-bearing applications, 2014 aluminum is often used alongside other high-strength aluminum alloys. For example, 2024 aluminum tube offers slightly better fatigue resistance and is preferred in aerospace skins and fittings, while 6061 aluminum tube provides a good balance between strength, corrosion resistance, and weldability, making it ideal for general engineering and structural use.

2014 aluminum tube chemical composition

| Element | Component % |

| Aluminum (Al) | 90.4 to 95 |

| Copper (Cu) | 3.9 to 5.0 |

| Silicon (Si) | 0.5 to 1.2 |

| Manganese (Mn) | 0.4 to 1.2 |

| Magnesium (Mg) | 0.2 to 0.8 |

| Iron (Fe) | 0 to 0.7 |

| Zinc (Zn) | 0 to 0.25 |

| Zirconium (Zr) | 0 to 0.2 |

| Titanium (Ti) | 0 to 0.15 |

| Chromium (Cr) | 0 to 0.1 |

| Residuals | 0 to 0.15 |

2014 aluminum tube mechanical properties reference table

| Temper | Ultimate Tensile Strength MPa R m | Yield Strength MPa R p0.2 | Elongation A (%) |

| T3 | 380 | 290 | 8 |

| T4 | 380 | 240 | 12 |

| T6 | 450 | 380 | 8 |

| T6510 | 435 | 390 | 7 |

MASTAR 2014 aluminum tube performance advantages

- High Strength: With excellent tensile strength and yield strength, it is suitable for applications that need to withstand high loads and pressures.

- Good fatigue resistance: Able to maintain stable performance under repeated loads, suitable for structures and components requiring durability.

- Excellent machinability: easy to process and shape, suitable for various processing techniques, and can meet different design requirements.

- Lower coefficient of thermal expansion: less deformation in high temperature environments, helping to maintain structural stability.

- Poor corrosion resistance: requires a protective coating to avoid corrosion.

MASTAR 2014 aluminum tube cooperation areas

- Aerospace: For structural airframe components requiring both strength and fatigue resistance, 2014 forged tube is often used in combination with 2024 and 7075 aluminum tube in various assemblies.

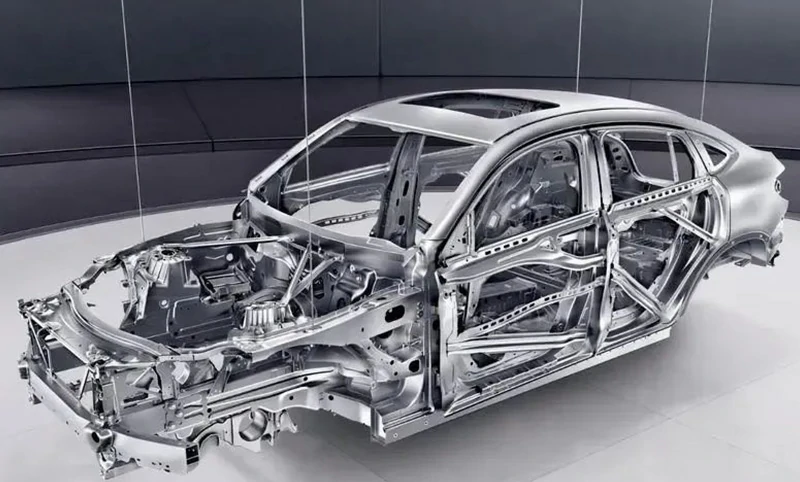

- Automobile Manufacturing: In performance and chassis components, 6061 and 2A12 aluminum tube are also frequently used alongside 2014 for different load-bearing functions.

- Industrial Structures: For high-pressure pipe systems, consider seamless aluminum tube or thick wall aluminum tube options based on your pressure class and tolerance requirements.

Why MASTAR became the preferred supplier of aluminum tubes in 2014

- Fast Delivery: We have abundant inventory to ensure fast shipment of any product, saving time for your project.

- Customized service: MASTAR can provide customized service according to customer needs. You only need to inform the length, quantity, surface finish, cutting, bending, color coating, end use and other special requirements.

- Competitive Price: Our products are priced competitively and we offer reasonable discounts for large quantities, giving you better prices and quality service.

- After-sales support: We provide fast after-sales support to ensure that you get timely help and support when using our products.

Explore more high-strength aluminum tubes

- 2024 Aluminum Tube – High fatigue resistance, ideal for aerospace fittings.

- 7075 Aluminum Tube – Superior strength, used in aviation and tooling.

- 6061 Aluminum Tube – Versatile alloy with excellent weldability and corrosion resistance.

- 2A12 Aluminum Tube – Widely used in transportation and heavy-duty structures.

- Seamless Tube & Pipe – For high-pressure or critical tolerance systems.

- Thick Wall Aluminum Tube – For heavy-load mechanical assemblies.