3003 aluminum rod bar is an aluminum alloy with manganese as the primary alloying element, also known as "rust-proof aluminum." It features excellent formability, corrosion resistance, and workability. Compared to the 1000 series aluminum, 3003 aluminum alloy has about 20% higher strength, and its strength can be further increased through cold working.

Due to its good corrosion resistance, the 3003 aluminum rod is commonly used in outdoor projects and equipment that comes into contact with chemicals, such as storage tanks, pipelines, chemical equipment, kitchenware, and decorative parts. Additionally, it has high thermal and electrical conductivity, making it suitable for applications requiring efficient heat dissipation.

Click here to view the 3003 Aluminum Rod Product Guide

As a professional aluminum supplier, Mastar can customize EN and ASTM standard aluminum rods based on customer requirements. All materials undergo strict testing before shipment, with quality inspection reports provided as proof of quality.

Mastar offers various aluminum rod processing methods, including extruded rods, cold-worked rods, and cast billets, with the following size range:

- 3003 extrusion aluminum bar

- Temper: F, O, H111, H112

- DIA: 0.4"-16"(10-420mm)

- Spec:ASTM B221, EN 755

- 3003 aluminum cold-finished bar

- Temper: H12, H14, H16, H18

- DIA: 0.125"-8" (3-200mm)

- Spec: AMS-QQ-A-225/2, ASTM B211

- 3003 aluminum cast billets bar

- Temper: F

- DIA: 4.8"-53" (124-1350mm)

- Material used for subsequent extrusion production

If you need more information about the 3003 aluminum rod bar or have customization needs, feel free to contact our professional team for the best solution.Quick Quote

Popular 3003 aluminum rod products

3003 O/F aluminum rod bar

The 3003 O aluminum rod is in its softest state, offering the highest ductility compared to other 3003 aluminum variants. It is especially suitable for applications requiring extensive forming, bending, or reshaping without cracking. The H111 aluminum rod undergoes light cold working, offering slightly higher strength than the O temper while maintaining good formability.

3003 F/H112 aluminum rod bar

The 3003 H112 aluminum rod is similar to the F temper but allows for limited strain hardening or heat treatment under specific conditions. It maintains good workability with moderate strength, making it suitable for applications requiring good formability and corrosion resistance, such as construction, pipelines, and storage tanks.

3003 H12 aluminum rod bar

The 3003 H12 aluminum rod undergoes moderate strain hardening, with its strength falling between the O temper (annealed) and fully hard (H18) states. It provides moderate strength and good formability, ideal for applications that require moderate strength and further processing, such as pipelines, chemical equipment, and storage tanks.

3003 H14/H16 aluminum rod bar

The 3003 H14/H16 aluminum rods undergo more significant strain hardening, with strength between the annealed (O temper) and fully hard (H18) states. They offer good corrosion resistance and higher strength while maintaining good formability, making them suitable for medium-strength applications like metal products, chemical equipment, and tank containers.

3003 H18 aluminum rod bar

The H18 temper represents the fully hard state of the 3003 aluminum rod, achieved through complete strain hardening for maximum strength. Due to its high strength and low ductility, the H18 aluminum rod is ideal for applications that do not require further processing, such as building materials, decorative parts, and environments requiring high corrosion resistance.

3003 H14 Aluminum wire rod

Size: 3-10mm

The 3003 H14 aluminum wire is strain-hardened, offering medium strength, good formability, and corrosion resistance. It is widely used in the automotive industry, fastener manufacturing, and electronic devices. It is particularly suitable for manufacturing automotive brake rivets.

3003 aluminum round bar

Diameter: 5-420mm

The round-section aluminum rod is the most commonly used shape. It can be extruded into microchannel aluminum tubes and custom decorative parts. It is typically used in heat exchangers, chemical equipment, and tank fittings.

3003 aluminum square bar

Size: 10x10mm to 200x200mm

The square-section aluminum bar offers good machinability and weldability. It is suitable for a wide range of industrial fields such as construction, chemical processing, food processing, and machinery manufacturing.

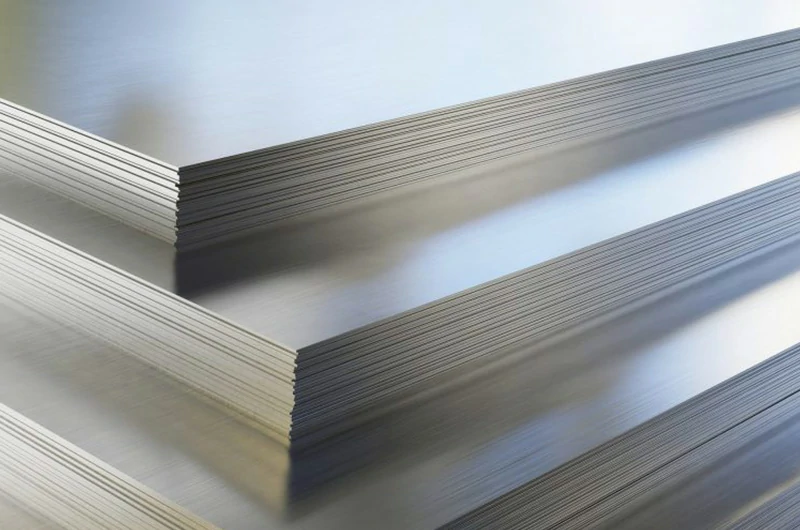

3003 Aluminum Flat Bar

Size: 10x12mm to 100x250mm

The rectangular-section aluminum bar provides moderate strength, good corrosion resistance, and easy workability. It is commonly used in industrial applications that require corrosion resistance, formability, and adequate strength, such as construction, food processing, chemical equipment, and storage systems.

EN-AW 3003 aluminum rod stock chart

| Description | Alloy | Diameter (in) | Diameter (mm) | Weight (kg/m) |

| 3.149" 3003 H112 Aluminum Bar | 3003 | 3.149 | 80 | 13.72 |

| 3.937" 3003 H112 Aluminum Bar | 3003 | 3.937 | 100 | 21.44 |

| 4.331" 3003 H112 Aluminum Bar | 3003 | 4.331 | 110 | 25.94 |

| 4.724" 3003 H112 Aluminum Bar | 3003 | 4.724 | 120 | 30.88 |

| 5.118" 3003 H112 Aluminum Bar | 3003 | 5.118 | 130 | 36.24 |

| 5.512" 3003 H112 Aluminum Bar | 3003 | 5.512 | 140 | 42.03 |

| 5.906" 3003 H112 Aluminum Bar | 3003 | 5.906 | 150 | 48.24 |

| 9.449" 3003 H112 Aluminum Bar | 3003 | 9.449 | 240 | 123.5 |

| 11.024" 3003 H112 Aluminum Bar | 3003 | 11.024 | 280 | 168.1 |

| 11.811" 3003 H112 Aluminum Bar | 3003 | 11.811 | 300 | 192.97 |

Don't see the size you need in the stock chart above? If the diameter meets your project requirements, we can provide custom-cutting services. Alternatively, contact our sales manager for customization options. Quick Quote

What can we offer you as a high-quality aluminum rod supplier?

- Price Advantage: We support both retail and bulk purchases for metal distributors, offering discounts and rebate policies for B2B customers. Our pricing is transparent, ensuring a competitive advantage with equivalent-quality aluminum rods.

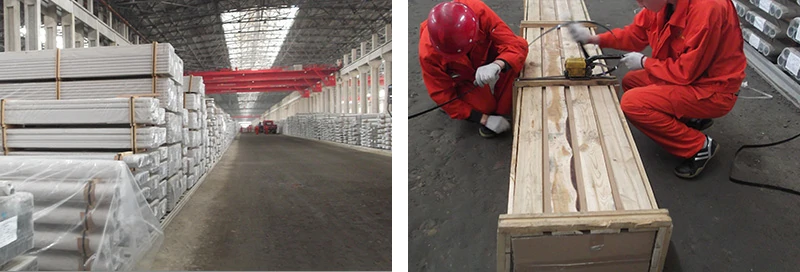

- Fast Delivery: With over 10,000 tons of stock, standard sizes can be matched with existing inventory, ensuring quick shipment. Our advanced equipment and expert team help reduce lead times and provide efficient logistics for on-time delivery.

- High-Quality Products: We use premium aluminum rod billets, employing precise alloying and heat treatment processes to optimize the product's strength and ductility. Our uniform cooling and annealing processes ensure high tensile strength and superior performance.

- Excellent Grain Control: Produced via reverse extrusion, we control the cooling rate and homogenization process. The grain ring is typically controlled to ≤0.5mm, reducing defects and improving material consistency.

- Comprehensive Quality Testing: We strictly implement multiple inspection processes, including tensile strength, elongation performance, ultrasonic testing, and metallographic inspection, ensuring that our aluminum rods meet AMS, EN, and NADCAP certification standards.

- Customer Service: We provide full after-sales support to resolve customer concerns. Our experienced technical team offers professional consultation and guidance, ensuring an excellent customer service experience.

Key characteristics of 3003 aluminum rod bar

- Moderate Strength: About 20% stronger than 1100 series aluminum, suitable for applications that do not require extremely high strength.

- Excellent Corrosion Resistance: Provides good resistance to atmospheric and chemical corrosion, making it ideal for use in outdoor and corrosive environments.

- Outstanding Workability: Easy to machine, weld, and braze, making it suitable for producing various metal products and structural components.

- Good Weldability: Compatible with various welding methods such as MIG and TIG, offering reliable weldability without requiring special treatment.

- High Thermal Conductivity: Capable of effectively dissipating heat, making it ideal for applications such as heat exchangers and electronic devices.

With these well-balanced properties, 3003 aluminum is available not only as rod and bar, but also in tube, coil, and sheet forms — providing flexible solutions for a wide range of fabrication and project needs.

Best application areas for 3003 aluminum rod bar

3003 Aluminum Rod Bar for Heat Exchangers

3003 Aluminum Rod Bar for Heat Exchangers- With a thermal conductivity of 180 W/m-K, it quickly transfers heat, improving heat transfer efficiency, and making it ideal for heat exchanger applications such as automotive radiators, air conditioning systems, air conditioner heat exchangers, and industrial heat exchangers.

3003 Aluminum Rod Bar for Aerospace

3003 Aluminum Rod Bar for Aerospace- Due to its good formability, excellent corrosion resistance, and high thermal conductivity, it is suitable for aircraft and spacecraft heat exchange systems, cooling pipes, liquid storage tanks, fuel pipes, gas processing equipment, and other non-load-bearing components.

3003 Aluminum Rod Bar for Chemical Equipment

3003 Aluminum Rod Bar for Chemical Equipment- Known as rust-proof aluminum, 3003 aluminum is ideal for chemical equipment such as chemical storage tanks, pipelines, and reaction vessels. It resists chemical corrosion and offers good weldability and workability, making it easy to manufacture complex equipment that meets the chemical industry's demands.

3003 Aluminum Rod Bar for Storage Tanks

3003 Aluminum Rod Bar for Storage Tanks- Widely used in applications requiring safe storage and high-strength sealing, such as food processing tanks, chemical tanks, and liquid storage tanks. The addition of manganese helps maintain stability and resist corrosion when in contact with liquid chemicals.

3003 aluminum rod procurement guide

1. Complete Documentation Reports

Mastar provides detailed quality test reports, including raw material certificates, lab test reports, fumigation reports, specification guides, commercial invoices, and warranty certificates, ensuring complete transparency and traceability for every batch of products.

2. Fine Export Packaging

In international shipping, goods must pass through various channels before reaching their final destination. The quality of packaging materials directly determines whether the goods will rust, corrode, scratch, deform, or suffer other damage during transportation, making high-quality packaging materials crucial.

With years of export packaging experience, Mastar offers thousands of companies safe and reliable packaging solutions. By using fumigated wooden crates, wooden pallets, and other premium materials, our packaging damage rate is only one-third of the industry average.

3. Professional Container Loading Solutions

Our experienced tracking team offers flexible container loading solutions, including 20/40-foot containers or bulk carriers. Regardless of the size or shape of your goods, we can customize a detailed loading solution, typically saving 15% of container space, thus reducing logistics costs.

3003 aluminum rod product guide

3003 aluminum alloy equivalent grades

| UNS | EN | DIN | ISO | USA | WNR | OLD |

| A93003 | EN AW-3003 | AlCuMg2 | AlCu4Mg | AA3003 | 3.0517 | AU4G1 |

Why is the 3003 aluminum rod bar highly corrosion-resistant?

The primary alloying element in 3003 aluminum alloy is manganese, which enhances the aluminum's corrosion resistance, especially in atmospheric and chemical environments. This is one of the key reasons 3003 aluminum is ideal for outdoor and chemical equipment applications.

| Element | EN AW-3003 |

| Si | 0.60 |

| Fe | 0.70 |

| Cu | 0.05-0.20 |

| Mn | 1.0-1.5 |

| Mg | - |

| Cr | - |

| Zn | 0.10 |

| Ti | - |

| Others (Each) | 0.05 |

| Others (Total) | 0.15 |

| Al | Rem |

Why does 3003 aluminum rod bar have excellent thermal conductivity?

The thermal conductivity of 3003 aluminum rods is 180 W/m-K, allowing them to quickly transfer heat. Its relatively high specific heat capacity helps absorb and dissipate heat, maintaining temperature stability. The moderate thermal expansion coefficient reduces deformation or cracking, making it particularly suitable for heat exchangers.

| Thermal Properties | Value |

| Latent Heat of Fusion | 400 J/g |

| Maximum Temperature: Mechanical | 180 °C |

| Specific Heat Capacity | 900 J/kg-K |

| Thermal Conductivity | 180 W/m-K |

| Thermal Expansion | 23 µm/m-K |

Physical properties of 3003 aluminum rod bar

| Physical Property | Value |

| Density | 2.73g/cm³ |

| Melting Point | 640-650 °C |

| Thermal Expansion | 23 µm/m-K |

| Modulus of Elasticity | 70 GPa |

| Thermal Conductivity | 180 W/m.K |

| Electrical Conductivity | 44% IACS |

How does the mechanical strength of 3003 aluminum rod bar change?

As a typical cold-worked aluminum rod, the mechanical strength of 3003 aluminum varies depending on the degree of cold working.

| Mechanical Properties | F/H112 | O/H111 | H14 | H16 | H18 |

| Tensile strength Rm/Mpa | 95 | 95-135 | 130-165 | 160-195 | 180 |

| Yield strength Rp0.2/Mpa | 35 | 35 | 110 | 130 | 145 |

| Elongation | 20-25% | 20-25% | 4-6% | 3-4% | 2-3% |

| Hardness | 30 | 30 | 40 | 47 | 55 |

3003 aluminum rod bar standards

- AMS-QQ-A-225/2 - Aluminum Alloy 3003, Bar, Rod, and Wire; Cold Finished

- EN 755 - Aluminum and Aluminum Alloys - Extruded Rod/Bar, Tube and Profiles

- EN 754 - Aluminum and Aluminum Alloys - Cold Drawn Rod/Bar, Tube and Profiles

- ASTM B221 - Aluminum and Aluminum-Alloy Extruded Bars, Rods, Wire, Profiles, and Tubes

- ASTM B211 - Aluminum and Aluminum-Alloy Rolled or Cold Finished Bar, Rod

3003 polished aluminum rod vs. 3003 cold-worked aluminum rod

Polishing and cold-working are two different processes that impact the surface finish and performance of aluminum rods. The differences are as follows:

| Features | 3003 polished aluminum rod | 3003 cold finished aluminum rod |

| Organization structure | Basically unchanged | Internal grain structure is denser |

| Strength | Basically unchanged | Greatly enhanced |

| Plasticity | Basically unchanged | Greatly reduced |

| Corrosion resistance | Slightly reduced | Basically unchanged |

| Surface | Smooth surface, mirror effect | With a certain degree of roughness |

| Application | Decorative materials, exterior parts | Mechanical parts, structural parts |

1100 aluminum rod vs. 3003 aluminum rod

Both 1100 aluminum rods and 3003 aluminum rods are non-heat-treatable alloys with relatively low strength. The main differences are:

- Alloy Composition: 1100 aluminum contains 99% aluminum, offering excellent corrosion resistance and workability, but it has lower strength. 3003 aluminum, on the other hand, contains a small amount of manganese (around 1.2%), making it stronger than 1100 aluminum and significantly enhancing its corrosion resistance.

- Strength: 1100 aluminum has lower strength, making it suitable for applications requiring extreme ductility and formability. 3003 aluminum is approximately 20% stronger than 1100 aluminum, making it suitable for applications requiring moderate strength and easy formability.

- Formability and Weldability: 1100 aluminum has excellent formability, making it easy to weld and process. While 3003 aluminum is slightly less formable, it offers good weldability and workability, making it ideal for processing complex shapes.

While 3003 aluminum rod stands out for its balance of strength and corrosion resistance, there are also several related alloys commonly used in similar applications. Options like 3105, 3004, and 5052 provide additional choices for customers seeking slightly different performance characteristics across various product forms.