3A21 is a typical Al-Mn series rust-resistant aluminum alloy, featuring high plasticity, good corrosion resistance, and moderate strength. Since it cannot be strengthened by heat treatment, its mechanical properties are relatively low, but its strength can be enhanced through cold working.

In the annealed state, this alloy exhibits extremely high plasticity, while in a cold-worked hardened state, plasticity is somewhat reduced. The 3A21 aluminum bar is commonly used in products such as rivets, liquid containers, oil tank ducts, heat exchangers, and structural components, where high ductility and good corrosion resistance are essential.

Click to view the 3A21 Aluminum Bar Product Guide.

Popular Products of 3A21 Aluminum Bar

3A21 Aluminum Round Bar

Diameter: 10-200mm

3A21 aluminum round bar is widely used in machinery, automotive, and equipment manufacturing for its good machinability, corrosion resistance, and consistent ductility — ideal for tough, non-heat-treated components.

Find more round bar products in Mastar

Key Features:

- High corrosion resistance, making it ideal for marine and outdoor applications.

- Excellent formability and weldability, suitable for custom processing.

- Commonly used in parts that require strength without sacrificing flexibility, such as pipes and automotive components.

3A21 Aluminum Square Bar

Side Length: 10mm - 150mm

The 3A21 aluminum square bar is an ideal choice for applications requiring sturdy support in construction. It offers good machinability and high plasticity, often used in structural projects requiring precise dimensions, such as support columns and beams.

Find more square bar products in Mastar

Key Features:

- Strong corrosion resistance ensures durability even in high-humidity environments.

- Suitable for frame structures in construction, requiring high rigidity and stability.

- Easily machinable to custom specifications, reducing labor costs and material waste.

3A21 Aluminum Flat Bar

Thickness: 5-100mm

The 3A21 aluminum flat bar is widely used in framing, support, and bracket systems. Due to its non-heat-treatable strengthening feature, it maintains high flexibility during cold working, making it easy to form.

Find more flat bar products in Mastar

Key Features:

- Good fatigue strength, ideal for dynamic load applications like platforms or frames.

- Common in the railway and shipping industries for its balance between strength and weight.

- The flat bar design provides excellent coverage, allowing wider structures to be created with less material.

3A21 Aluminum Hex Bar

Across Flats Dimension: 10-80mm; Thickness: 5-100mm

The 3A21 aluminum hex bar is commonly used in heavy machinery structures for fasteners like bolts and nuts. The hexagonal shape provides enhanced gripping and fastening capabilities.

Find more hex bar products in Mastar

Key Features:

- Hexagonal geometry for easier gripping during assembly.

- Excellent machinability and weldability, facilitating precise part manufacturing.

- Widely used in high-stress fastening applications requiring both strength and corrosion resistance.

3A21 Extrusion Aluminum Bar

Diameter: 10-420mm

The 3A21 extruded aluminum bar is suitable for complex profiles requiring custom shapes. Through extrusion, 3A21 can be formed into various shapes, making it highly adaptable in industrial sectors requiring custom components.

Click to discover extrusion process

Key Features:

- Suitable for custom industrial components with specific mechanical requirements.

- High resistance to stress corrosion and cracking.

- Used in fields like aerospace, where precision-engineered components are essential.

3A21 Cold Finished Aluminum Bar

Diameter: 10-200mm

The 3A21 cold finished aluminum bar is processed through cold drawing, providing high precision in diameter and surface finish, making it ideal for applications requiring strict material tolerance and surface quality. It is commonly used in the manufacture of high-precision components, such as machined parts and structural components.

Key Features:

- Cold drawing process offers precise dimensional control, suitable for high-precision requirements.

- Excellent surface finish from the cold drawing process, reducing the need for further finishing.

- Ideal for producing high-quality parts with strict dimensional and surface requirements, such as mechanical components and aerospace structural parts.

Cold heading of 3A21 aluminum wire rod

3A21 aluminum wire rod for cold heading is suited for applications that require good cold heading properties, playing an important role in the production of fasteners and rivets. With its high plasticity and good corrosion resistance, this aluminum wire rod is ideal for forming high-strength parts through cold heading.

Key Features:

- High plasticity allows the formation of complex-shaped fasteners and rivets through cold heading.

- Excellent corrosion resistance ensures long-term durability of finished products in various environments.

- Suitable for high-efficiency production with outstanding machinability in the cold heading process, reducing processing time and costs.

3A21 Cast Aluminum Bar

The 3A21 cast aluminum bar is designed for applications requiring specific shapes, with the casting process allowing the creation of complex geometries. It is suitable for applications needing customized fits.

Key Features:

- Ideal for complex parts requiring specific shapes.

- Provides excellent thermal stability and dimensional stability.

- Commonly used in engine parts and other precision machinery where accuracy is essential.

What We Can Offer as a High-Quality Aluminum Bar Supplier

- Premium Products: Using high-quality aluminum billets, we employ precise alloying and heat treatment processes to optimize product strength and ductility, ensuring uniform cooling and annealing. This guarantees high tensile strength and superior performance.

- Excellent Grain Control: Produced through reverse extrusion processes, we control cooling rates and homogenization treatment. The coarse grain ring is typically controlled within ≤0.5mm, reducing quality defects, ensuring fine material structure, and enhancing product consistency.

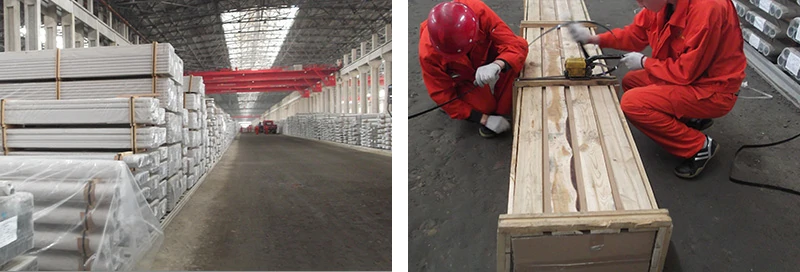

- Timely Delivery: With tens of thousands of tons in inventory, standard sizes can be directly matched to stock, ensuring rapid shipment. Advanced equipment and a professional team shorten delivery time, providing efficient logistics for on-time delivery.

- Competitive Pricing: Supporting both retail and bulk purchasing for metal distributors, we offer discounts and rebate policies for B2B clients. Pricing is transparent, and we ensure a price advantage for bars of the same quality.

- Comprehensive Quality Inspection: We strictly implement multiple inspection procedures, including tensile strength, elongation performance, ultrasonic testing, and metallographic testing to ensure that aluminum bars meet AMS, EN, NADCAP, and other certification standards.

- Customer Service: We provide comprehensive after-sales service to address customer concerns. Our experienced technical team offers professional consultation and guidance, establishing a robust customer service system to ensure a quality service experience.

Features of 3A21 Aluminum Bar

- Rust-Resistant Aluminum: The high manganese content in this alloy enhances its resistance to corrosion, particularly in marine and acidic environments.

- High Plasticity: Due to its non-heat-treatable strengthening, this alloy can be easily shaped, stretched, or bent without compromising its strength. It has extremely high plasticity in the annealed state, while plasticity decreases in the cold-work hardened state.

- Excellent Weldability: 3A21 aluminum can be used for gas welding, arc welding, and spot welding, with post-weld corrosion resistance comparable to that of the base metal, making it highly suitable for welded assemblies.

- Good Machinability: This alloy exhibits good machinability in both cold and hot states, with a broad hot deformation temperature range (320~470°C) and low sensitivity of deformation resistance to temperature and speed.

- Environmentally Friendly Material: As a fully recyclable material, 3A21 aligns with sustainable production practices, contributing to environmental protection and waste reduction.

Optimal Application Fields for 3A21 Aluminum Bar

Due to its high ductility and excellent resistance to environmental corrosion, 3A21 aluminum bar finds wide application across various industries.

- Rivets and Fasteners: The high plasticity of this material makes it ideal for forming rivets, which require on-site shaping and must retain high ductility in use.

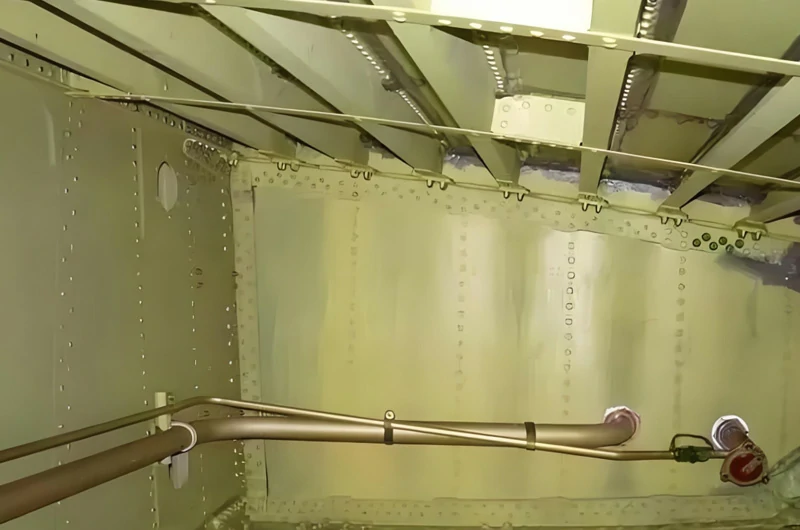

- Aerospace and Aviation: Its high corrosion resistance and easy machinability make it suitable for critical components like aircraft fuel tanks, oil conduits, and reflectors.

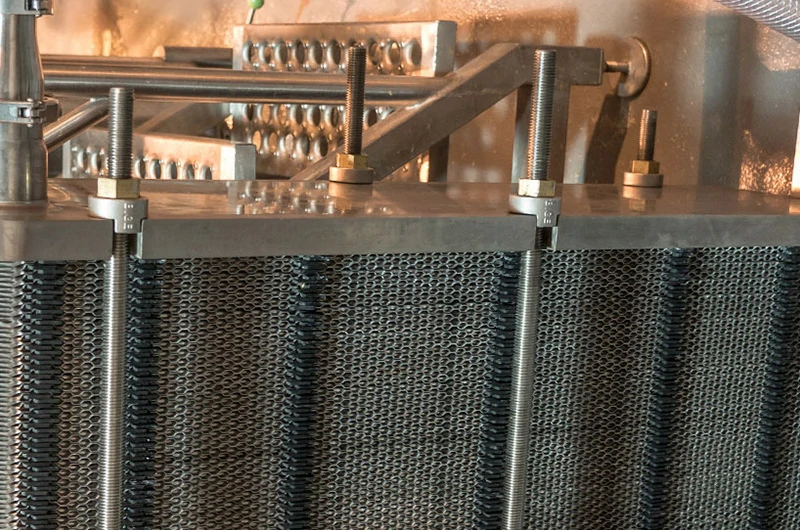

- Heat Exchangers: With good thermal conductivity and corrosion resistance, 3A21 aluminum is widely used in the manufacturing of heat exchangers and radiators. Its excellent machinability and weldability facilitate the production of complex heat exchange components.

- Fuel Tanks/Liquid Containers: Due to its excellent corrosion resistance and high plasticity, 3A21 aluminum bar is extensively used in applications such as fuel tanks, gasoline or lubricant conduits, various liquid containers, and other parts operating under low loads.

- Kitchen and Chemical Equipment: Owing to its excellent corrosion resistance, 3A21 aluminum is used in the processing and storage equipment for food and chemical products, as well as in liquid transport tanks.

3A21 aluminum bar procurement guide

1. Specifications and Dimensions

Choose the appropriate type and size of aluminum bar according to specific application requirements to ensure it meets design specifications and usage scenarios.

2. Quality Standards and Documentation Support

Ensure that the aluminum alloy bars purchased comply with international quality standards, such as ASTM B221, to guarantee that the material's mechanical properties and corrosion resistance meet project requirements. Msatar can provide detailed quality inspection reports, including raw material certificates, laboratory test reports, fumigation reports, specification guides, commercial invoices, and guarantees, ensuring transparency and traceability for each batch of products.

3. Inventory and Delivery Time

Check the supplier's inventory and delivery cycle to ensure materials arrive on time without impacting project schedules.

4. Export Packaging

In international shipping, packaging quality directly affects whether goods will suffer rust, corrosion, scratches, deformation, or other damages during transit. Msatar has extensive experience in export packaging, providing safe and reliable packaging solutions to thousands of companies. Using fumigated wooden boxes, wooden pallets, and other high-quality packaging materials, our packaging damage rate is only one-third of the industry average.

5. Loading Solutions

Our experienced order-following team can offer flexible loading solutions, including options for 20/40-foot containers or bulk shipments. Regardless of your cargo's specifications or shapes, we can customize a refined loading plan that saves an average of 15% in container space, effectively reducing your logistics costs.

Product Guide of 3A21 aluminum bar

Chemical composition of 3A21 aluminum bar

| Element | 3A21 |

| Si | 0.60 |

| Fe | 0.70 |

| Cu | 0.20 |

| Mn | 1.0-1.6 |

| Mg | 0.05 |

| Cr | - |

| Ni | - |

| Zn | 0.10 |

| Ti | 0.10 |

| Zr | - |

| Others (Each) | 0.05 |

| Others (Total) | 0.15 |

| Al | Rem |

Physical properties of 3A21 aluminum bar

| Properties | Value |

| Density | 2.70 g/cm³ |

| Melting point | 605°C |

| Thermal conductivity | 188 W/m·K |

| Coefficient of thermal expansion | 24µm/m·°C |

Mechanical properties of 3A21 extrusion aluminum bar

| Properties | O/H112 |

| Tensile strength Rm/MPa | 120-160 |

| Yield strength Rp0.2/MPa | 85 |

| Elongation | 20% |

What is the Difference Between 3003 and 3A21 Aluminum Alloys?

Answer: Both 3003 and 3A21 are aluminum-manganese series alloys, but 3A21 offers relatively higher plasticity and corrosion resistance, making it especially suitable for applications requiring high formability and rust resistance. Although 3003 has slightly higher strength, both alloys have good machinability in practice. However, 3A21 is more suitable for environments needing cold forming and corrosion resistance.

In addition to 3003 and 3A21, several other aluminum bar alloys with similar performance characteristics are also available. You can explore the options below for more material choices.

Why is 3A21 Considered a Typical Rust-Resistant Aluminum?

Answer: The 3A21 aluminum alloy contains a high amount of manganese, granting it excellent corrosion resistance, particularly in marine and acidic environments. Therefore, 3A21 is widely used in applications requiring high corrosion resistance, such as liquid containers, marine equipment, and outdoor facilities, earning it the designation of a typical rust-resistant aluminum.

Why is 3A21 Suitable for Fuel Tanks or Fuel Lines?

Answer: 3A21 aluminum alloy has good corrosion resistance and high plasticity, making it ideal for use in fuel tanks and fuel conduits. It can withstand the corrosive effects of fuels and lubricants while maintaining high ductility during forming to accommodate complex structural requirements. Additionally, its good weldability ensures airtightness and structural integrity for fuel tanks and conduits.