3003 aluminum alloy is a medium strength alloy with manganese as the main alloying element. 3003 has excellent atmospheric corrosion resistance, excellent weldability and good pressing, drawing and roll forming properties. Typical applications include storage tanks, pipes, heat exchangers, air conditioning evaporators, motor vehicle radiators, refrigerator liners, pipes and tubes.

MASTAR 3003 aluminum tube product introduction

Stock product types: 3003 aluminum tube coil; 3003 aluminum cold drawn seamless tube; 3003 extruded tube; 3003 aluminum alloy telescopic tube; 3003 aluminum alloy bent tube;

Equivalent Product Names: EN-AW-AlCu4Mg1; BS-AU4G1; WNr-3.0517; UNS-A93003; ISO-AlCu4Mg; USA-AA3003; DIN-AlCuMg2

Size: Hot sale diameter up to 500mm; MASTAR aluminum tube maximum outer diameter up to 1300mm, please consult for details

Schedule: SCH20, SCH30, SCH40, STD, SCH80, XS, SCH60, SCH80, SCH120, SCH140, SCH160, XXS

Surface treatment: mill finish, anodized, bright, black, polished …

Aluminum tube ends: flat end, bevel end, threaded end

MASTAR 3003 aluminum tube supply temper

- 3003 O

- O temper is the annealing state of 3003 aluminum alloy, which has the best ductility and formability.

- 3003 H14

- H14 is a hardening temper of 3003 aluminum alloy, which is achieved by cold working to a semi-hard temper.

- 3003 H112

- H112 is achieved through slight cold working or heat treatment during the manufacturing process.

- 3003 O aluminum tube is particularly suitable for applications that require severe deformation, as well as complex bending and forming operations. This state of aluminum tube is most suitable for those occasions where strength is not required but excellent formability is required.

- 3003 H14 aluminum tube has higher strength than the annealed state (O temper) while still maintaining good formability, making it particularly suitable for application scenarios requiring higher strength.

- 3003 H112 aluminum tube has a slightly higher strength than the O temper, but lower than the H14 state, while maintaining good formability and ductility. This temper of aluminum tube is suitable for applications requiring moderate strength and good formability, and is often used in the manufacture of pipes, structural parts and general purposes.

MASTAR 3003 aluminum coil tube

- 3003 aluminum alloy coil tube is produced by continuous extrusion or drawing process, easy to bend and good ductility, suitable for complex pipeline layout, reducing connections to reduce the risk of leakage. It is widely used in HVAC systems, automotive heat exchange pipelines and aerospace fuel lines.

How to choose 3003 aluminum coil tube or 1000 series aluminum coil tube

- Application requirements: 3003 series aluminum coil tubes are suitable for applications that require good strength and processability, such as construction, automobiles, and air-conditioning systems; 1000 series aluminum coil tubes are suitable for applications that require high conductivity and corrosion resistance, such as electrical conductors and chemical equipment.

- Mechanical properties: 3003 aluminum coil tube has high strength and good formability, suitable for applications requiring bending and welding; 1000 series aluminum coil tube has lower strength, but excellent conductivity and corrosion resistance, suitable for light load applications.

- Processability: 3003 aluminum coil tube is easy to process and form, suitable for complex manufacturing processes; 1000 series aluminum coil tube although the processability is better, it is not as flexible as 3003 aluminum coil tube.

- Cost: 3003 series aluminum coil tube: usually has a higher cost and is suitable for projects with strict performance requirements; 1000 series aluminum coil tube has a relatively low cost and is suitable for large-scale use.

- Environmental factors: Consider the corrosiveness and temperature range of the use environment and choose the appropriate aluminum alloy type to ensure long-term stability.

Mastar 3003 aluminum coil tube application field

The 3003 aluminum alloy coil, known for its excellent formability and corrosion resistance, is widely used in applications such as air conditioning and automotive radiators.

We offer a variety of aluminum alloy tubes suitable for coil production and processing, which can be customized to your specifications. Click here to explore other aluminum coil tubes and more aluminum tube alloy options. With our extensive inventory and processing capabilities, we can meet the needs of your project.

MASTAR 3003 aluminum alloy drawn seamless tube

- The drawn seamless pipe is manufactured through a drawing process, which makes its surface smooth, without welds, and has higher strength and precision. With the excellent corrosion resistance of 3003 alloy, this pipe is widely used in occasions with high requirements for sealing and structural strength, such as automotive oil pipes, hydraulic systems, air conditioning pipes and other fields.

| 3003 aluminum alloy drawn seamless pipe product mechanical properties reference table | ||||||

| Temper | Wall thickness mm | Ultimate Tensile Strength R m /MPa | Yield Tensile Strength Rp0.2/MPa | Elongation at Break % | ||

| Full Section Specimen | Other Specimens | |||||

| A 50mm | A 50mm | A | ||||

| O | All | 95-130 | 35 | - | 20 | 25 |

| H14 | All | 130-165 | 110 | - | 4 | 6 |

3003 drawn seamless pipe application areas

- Hydraulic system: suitable for hydraulic pipes and components due to its high strength and good sealing performance.

- Aerospace Components: Used in demanding aerospace applications, subject to high pressures and temperature changes.

- High-pressure piping: A piping system suitable for transporting high-pressure gases and liquids.

- Medical equipment: commonly used in the manufacture of high-precision medical instruments and equipment.

The 3003 aluminum alloy seamless pipe offers excellent corrosion resistance and good mechanical properties, making it widely used in high-demand fields such as hydraulic systems, medical equipment, and high-pressure pipelines. If your project requires other aluminum alloy seamless pipes, we provide a one-stop shopping experience. Explore more seamless pipe products, learn more about Mastar aluminum alloy seamless pipes, and discover additional aluminum tube alloy options.

MASTAR 3003 aluminum telescopic tube

- The size of 3003 aluminum telescopic tube is carefully designed, each tube can be inserted into a larger size, has excellent corrosion resistance and ductility, and can be freely extended to meet different needs. Its light weight, easy processing and anti-oxidation characteristics make it widely used in portable devices, telescopic poles, outdoor equipment and industrial fields.

The 3003 aluminum alloy telescopic tube is suitable for high-durability applications such as portable devices and outdoor equipment. Explore more applications and discover other aluminum alloy telescopic tubes that suit your project by visiting the aluminum alloy telescopic tube page or exploring more aluminum tube alloy options.

MASTAR 3003 aluminum alloy extruded tube

- Temper: O, H112

- Product Type: Extruded Seamless Pipe, Extruded Structural Pipe3003 aluminum alloy extruded tube is formed by extrusion process, with good strength and machinability. Extruded tube is suitable for applications requiring light weight and corrosion resistance, such as HVAC systems, construction and general industrial applications.

| 3003 aluminum alloy extruded tube mechanical properties reference table | |||||

| Temper | Wall thickness mm | Ultimate Tensile Strength R m /MPa | Yield Tensile Strength Rp0.2/MPa | Elongation at Break % | |

| A 50mm (%) | A(%) | ||||

| O | All | 95-130 | - | 25 | 22 |

| H112 | All | ≥95 | - | 25 | 22 |

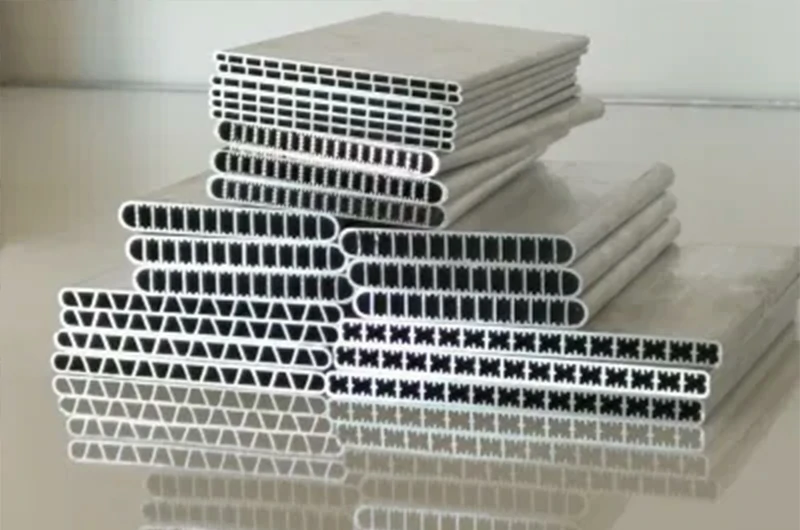

3003 aluminum tube can be extruded into:

3003 aluminum round tube, 3003 aluminum oval tube, 3003 aluminum square tube, 3003 aluminum rectangular tube, 3003 aluminum hexagonal tube, 3003 aluminum octagonal tube

3003 extruded tube application areas:

- Construction: Widely used in building structures and decorations due to its good machinability and corrosion resistance.

- HVAC systems: Pipes used for air conditioning and refrigeration equipment that meet the strength requirements of daily use.

- Furniture: Suitable for making furniture and household items, such as frames for tables and chairs.

- General industrial equipment: mostly used to manufacture equipment and components that do not withstand high loads and are suitable for mass production.

3003 aluminum tube bends

- 3003 aluminum alloy is composed of aluminum and manganese, with excellent machinability and weldability, making it an ideal choice for bending applications. It is widely used in automotive ducts, air conditioning condensers, construction and marine equipment, and is suitable for complex curved duct designs. We work with OEMs in various industries to produce custom components that meet MIL-I-45208A standards.

The 3003 aluminum alloy bent pipe offers excellent machinability and corrosion resistance, making it suitable for a variety of complex bending designs. Whether for industrial equipment or construction applications, we provide customized bent pipe solutions.

If your project requires more types of aluminum alloy bent pipes, please check the Mastar aluminum bent pipe product details.

For more information on bending technologies and other related services, visit the aluminum pipe bending services page to get customized bending solutions.

3003 aluminum tube chemical composition

| MASTAR 3003 Aluminum Tube Chemical Composition Reference Table | |

| Aluminum (Al) | 96.8 to 99 |

| Manganese (Mn) | 1.0 to 1.5 |

| Iron (Fe) | 0 to 0.7 |

| Silicon (Si) | 0 to 0.6 |

| Copper (Cu) | 0.050 to 0.2 |

| Zinc (Zn) | 0 to 0.1 |

| Residuals | 0 to 0.15 |

Mastar 3003 aluminum tube stock dimensions

| OD | ID | Wall Thick. |

| 5/64" | 0.050" | 0.014 " ( -0.002" to 0.002" Tolerance) |

| 7/64" | 0.081" | 0.014 " ( -0.002" to 0.002" Tolerance) |

| 9/64" | 0.113" | 0.014 " ( -0.002" to 0.002" Tolerance) |

| 11/64" | 0.144" | 0.014 " ( -0.002" to 0.002" Tolerance) |

| 13/64" | 0.175" | 0.014 " ( -0.002" to 0.002" Tolerance) |

| 15/64" | 0.207" | 0.014 " ( -0.002" to 0.002" Tolerance) |

| 1/4" | 0.218" | 0.016" (-0.002" to 0.002" Tolerance) |

| 9/32" | 0.249" | 0.016" (-0.002" to 0.002" Tolerance) |

| 5/16" | 0.280" | 0.016" (-0.002" to 0.002" Tolerance) |

| 11/32" | 0.312" | 0.016" (-0.002" to 0.002" Tolerance) |

| 3/8" | 0.343" | 0.016" (-0.002" to 0.002" Tolerance) |

| 13/32" | 0.374" | 0.016" (-0.002" to 0.002" Tolerance) |

| 7/16" | 0.405" | 0.016" (-0.002" to 0.002" Tolerance) |

| 15/32" | 0.436" | 0.016" (-0.002" to 0.002" Tolerance) |

| 1/2" | 0.468" | 0.016" (-0.002" to 0.002" Tolerance) |

| 17/32" | 0.499" | 0.016" (-0.002" to 0.002" Tolerance) |

| 9/16" | 0.530" | 0.016" (-0.002" to 0.002" Tolerance) |

| 5/8" | 0.593" | 0.016" (-0.002" to 0.002" Tolerance) |

Application field of Mastar 3003 aluminum tube pipe

3003 aluminum tube for Heat Exchange Systems

3003 aluminum tube for Heat Exchange Systems- The 3003 aluminum tube, known for its excellent thermal conductivity and corrosion resistance, is widely used in various heat exchange systems, including automotive cooling systems, HVAC air conditioning systems, refrigeration equipment, etc. It serves as cooling pipes or evaporator pipes in these systems, ensuring efficient operation and long-lasting durability.

Mastar offers a range of complementary products for heat exchange systems, such as coil tubes, finned tubes, microchannel tubes, and more, ensuring a complete solution for your project. From design to implementation, we meet diverse needs and help you achieve an efficient one-stop solution.

3003 aluminum tube for Pipeline Transportation Applications

3003 aluminum tube for Pipeline Transportation Applications- The 3003 aluminum tube is widely used in pipeline systems for chemical transportation, oil conveyance, and water treatment industries due to its outstanding corrosion resistance and durability. It ensures the long-term stability of pipeline systems and prevents corrosion from affecting the transported fluids.

3003 aluminum tube for Automotive Industry

3003 aluminum tube for Automotive Industry- The 3003 aluminum tube also plays a key role in the automotive industry, particularly in cooling and fuel pipe systems. Its lightweight nature and corrosion resistance make it an ideal choice for automotive cooling and heat dissipation pipes, helping improve fuel efficiency and extend component lifespan.

3003 aluminum tube for Aerospace Industry

3003 aluminum tube for Aerospace Industry- The corrosion resistance and machinability of 3003 aluminum tubes make them widely used in the aerospace industry. They are mainly employed in aircraft hydraulic systems, fuel lines, and air conditioning lines, capable of withstanding high pressure and extreme environments.

3003 aluminum tube for Marine Engineering

3003 aluminum tube for Marine Engineering- Due to the excellent corrosion resistance of 3003 aluminum tubes in seawater environments, it is widely used in marine engineering, especially in shipbuilding, seawater filtration systems, and cooling systems. Its anti-corrosion properties ensure long-term, stable use in harsh marine environments.

Why MASTAR is the preferred supplier of 3003 aluminum tube

- Fast Delivery: We have abundant inventory to ensure fast shipment of any product, saving time for your project.

- Customized service: MASTAR can provide customized service according to customer needs. You only need to inform the length, quantity, surface finish, cutting, bending, color coating, end use and other special requirements.

- Competitive Price: Our products are priced competitively and we offer reasonable discounts for large quantities, giving you better prices and quality service.

- After-sales support: We provide fast after-sales support to ensure that you get timely help and support when using our products.

3003 aluminum tube related knowledge base and buying guide

3003 aluminum tube and 6061 aluminum tube

Both 3003 aluminum and 6061 aluminum are suitable for general manufacturing purposes, and the differences in alloy properties include:

- 3003 aluminum has better formability than 6061 aluminum

- 3003 aluminum has better weldability than 6061 aluminum

- 3003 aluminum has good corrosion resistance, while 6061 aluminum has excellent corrosion resistance

- 3003 is not heat treatable, while 6061 aluminum is heat treatable

3003 aluminum tube and 6063 aluminum tube

While both 3003 aluminum and 6063 aluminum have moderate strength, the differences between them include:

- 3003 aluminum has medium strength, while 6063 aluminum has medium to high strength

- 3003 aluminum cannot be heat treated. 6063 aluminum can be heat treated

- 3003 aluminum has better machinability than 6063 aluminum

- 3003 aluminum has better weldability than 6063 aluminum

Annealing treatment of 3003 aluminum tube

Annealing is a heat treatment process that increases the ductility and formability of aluminum tubes. For 3003 aluminum tubes, the annealing treatment is usually carried out at a temperature range of 375°C to 425°C, and the duration depends on the thickness of the material and the required properties.

Bending of 3003 aluminum tube

3003 aluminum tube is easy to bend due to its good formability. Here are some suggestions for bending processing:

Use an appropriate bend radius, usually not less than 3 times the outside diameter of the tube.

For complex bends, consider using filler material to prevent wrinkling of the tube wall.

Annealing can be performed before bending to improve the plasticity of the material.

Welding 3003 aluminum tube

3003 aluminum alloy has good weldability. Commonly used welding methods include:

- TIG (Tungsten Inert Gas) welding

- MIG (Metal Inert Gas) welding

- Resistance welding

When welding, it is recommended to use 4043 or 5356 aluminum welding wire and ensure that the welding area is clean and free of contamination.

3003 aluminum tube buying guide

When choosing the right 3003 aluminum tube, consider the following factors:

- Application Environment: Consider the environment to which the product will be exposed to determine the required corrosion resistance.

- Strength requirements: Select the appropriate hardness grade (such as O or H14) based on your application.

- Dimensions: Determine required outside diameter, wall thickness and length.

- Surface treatment: Consider whether additional surface treatments such as anodizing or coating are required.

- Quantity: Order in bulk to enjoy better prices.