Specifications of 5049 aluminum tube

- EN 755

- EN 754

- EN 573

- EN 1592

- EN 12392

- IATF16949

Popular 5049 aluminum tube products

5049 Extruded Aluminum Tube

5049 Extruded Aluminum Tube- 5049 extruded aluminum tube offers excellent strength and corrosion resistance, widely used in structural components.

5049 Drawn Aluminum Tube

5049 Drawn Aluminum Tube- 5049 drawn aluminum tube has high precision, suitable for manufacturing precision parts.

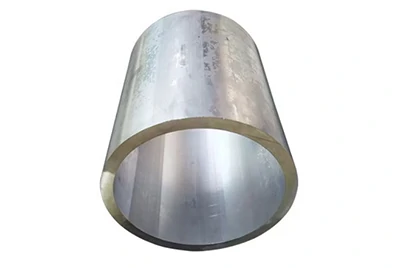

5049 Forged Tube

5049 Forged Tube- 5049 forged tube has high strength, ideal for high-load industrial environments.

5049 Seamless Tube

5049 Seamless Tube- 5049 seamless tube features seamless connections and strong corrosion resistance.

- Click to find more seamless tube products in MASTAR

Mastar offers 5049 aluminum tubes through multiple processing methods, including extrusion, drawing, forging, and seamless forming — each tailored for different mechanical and structural needs. You can also click to explore our full range of aluminum tube products, understand their performance advantages, and view related alloy products that match your application requirements.

Popular shapes of 5049 aluminum tube

We offer 5049 aluminum tubes in various tempers, such as O, H112, F, T4, and T6. Sizes are flexible and can be customized according to customer requirements.

5049 Round Tube

5049 Round Tube- Diameter: 3mm - 220mm

- Wall Thickness: According to customer requirements

- Length: 1 - 6m

5049 Square Tube

5049 Square Tube- Side Length: 20mm - 100mm

- Wall Thickness: According to customer requirements

- Length: 1 - 6m

5049 Rectangular Tube

5049 Rectangular Tube- Width: 20mm - 100mm

- Height: 20mm - 80mm

- Wall Thickness: According to customer requirements

- Length: 1 - 6m

5049 aluminum tubes are available in round, square, and rectangular shapes. We also stock custom cross-sectional aluminum tubes in other high-performance alloys, enabling flexible solutions for structural and design requirements.

Chemical elements of 5049 aluminum tube (EN 573-3)

| Chemical Element | % Present |

| Si | 0.40 max |

| Fe | 0.50 max |

| Cu | 0.10 max |

| Mn | 0.50 - 1.1 |

| Mg | 1.6 - 2.5 |

| Cr | 0.30 max |

| Zn | 0.20 max |

| Ti | 0.10 max |

| Other (Each) | 0.05 max |

| Others (Total) | 0.15 max |

| Aluminium (Al) | Remainder |

Physical properties of 5049 aluminum tube

| Physical Property | Value |

| Density | 2.70 g/cm³ |

| Melting Point | 650 °C |

| Thermal Expansion | 24 x10^-6 /K |

| Modulus of Elasticity | 69 GPa |

| Shear Modulus | 26 GPa |

| Thermal Conductivity | 140 W/m.K |

| Electrical Resistivity | 35 % IACS |

Mechanical properties of 5049 extruded aluminum tube (EN 755)

| Temper | Wall thickness (mm) | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Hardness (HB) |

| F, H112 | All | Min. 180 | Min. 80 | 15 | 50 |

Mechanical properties of 5049 drawn aluminum tube (EN 754)

| Temper | Wall thickness (mm) | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Hardness (HB) |

| O, H111 | ≤ 20 | Min. 180 Max. 250 | Min. 80 | 17 | 50 |

| H11 | ≤ 17 | Min. 195 Max. 260 | Min. 100 | 13 | 58 |

| H12 | ≤ 15 | Min. 210 Max. 270 | Min. 120 | 10 | 65 |

| H13 | ≤ 12 | Min. 225 Max. 280 | Min. 140 | 7 | 70 |

| H14 | ≤ 10 | Min. 240 Max. 290 | Min. 160 | 4 | 75 |

| H15 | ≤ 7 | Min. 250 Max. 300 | Min. 180 | 3 | 80 |

| H16 | ≤ 5 | Min. 260 Max. 310 | Min. 200 | 3 | 83 |

| H17 | ≤ 4 | Min. 270 Max. 320 | Min. 220 | 2 | 85 |

| H17 | ≤ 3 | Min. 280 | Min. 240 | 2 | - |

5049 aluminum tube features a strong balance of corrosion resistance, strength, and weldability — making it ideal for structural and marine-grade applications. If you're seeking aluminum alloys with comparable performance, you may also explore 5083 aluminum tubes for superior marine corrosion resistance, or 5754 aluminum tubes for enhanced pressure resistance and weldability in storage tanks and transport equipment. For similar mechanical strength in aerospace and automotive fields, 6061 aluminum tubes are also widely used. Mastar stocks a full range of these performance-grade alloys to support your material selection needs.

Advantages of 5049 aluminum tube

- Strong Corrosion Resistance: Especially suitable for use in marine and chemical environments.

- High Strength: Excellent mechanical properties, ideal for high-load applications.

- Good Weldability: Easy to weld, suitable for various manufacturing processes.

- Easy Machinability: Can be cold-formed and precisely processed to meet different needs.

- Lightweight: Lighter than steel, helping to reduce the overall weight of structures.

- Good Abrasive Resistance: Suitable for high-wear environments.

Applications of 5049 aluminum tube

5049 aluminum tubes are widely used in hull structures, decks, and marine piping systems due to their excellent corrosion resistance and weldability in saltwater environments.

We also provide 5083 marine-grade aluminum tubes and 5456 aluminum tubes optimized for shipbuilding applications, allowing you to build a complete corrosion-resistant marine solution.

5049 tubes are used in vehicle body structures, coolant systems, and structural reinforcement parts for their lightweight and high strength.

If you're looking for alternatives with excellent formability and welding performance, consider our 5A06 automotive aluminum tubes or 6061 structural tubing — both readily available for fast integration into automotive systems.

In aerospace, 5049 aluminum is suitable for lightweight support structures and equipment frames where moderate strength and corrosion resistance are required.

For critical load-bearing aerospace components, we also offer 2024 high-strength aerospace tubes and 7075 precision tubes, enabling you to build a full-spectrum structural solution.

5049 aluminum tubes provide excellent strength and surface durability in construction and infrastructure, especially where long service life and corrosion resistance are essential.

You can also explore 6063 anodized architectural tubes and 6082 structural aluminum tubes for curtain wall frames, supports, and façade systems — all customizable for your construction projects.

5049 tubes are ideal for high-load machine structures, frames, and piping in corrosive or abrasive environments, thanks to their balanced mechanical properties.

We also supply 2A12 high-strength tubes and 6061 heat-treated structural tubes for demanding industrial use — contact us to customize your system design.

- Power & Communication: Used in towers and electrical facilities.

- Sports Equipment: Used in frames and furniture.

Anodizing of 5049 aluminum tube

5049 aluminum tube can undergo anodizing treatment to enhance surface corrosion resistance and hardness, improve appearance, and provide a wider range of color options.

This process is suitable for industries that require both aesthetics and durability, such as construction and automotive.

To learn more about surface finishing techniques and their industrial benefits, please refer to our detailed guide on aluminum surface treatment.

Welding of 5049 aluminum tube

5049 aluminum tube has excellent weldability and is commonly welded using TIG (Tungsten Inert Gas) or MIG (Metal Inert Gas) welding techniques.

After welding, the strength remains high, making it suitable for structural components and industrial applications.

If you're exploring optimal welding techniques for aluminum tubes, feel free to visit our article on aluminum tube welding methods for more technical insights and project recommendations.

Supplier of 5049 aluminum tube - our advantageous services

Custom Services: We provide custom options based on customer requirements, such as different sizes, surface treatments, and processing methods.

Fast Delivery: We maintain sufficient stock of standard sizes and specifications to ensure prompt shipping.

Competitive Prices: We offer competitive pricing and provide discounts for bulk orders.

After-Sales Support: Comprehensive after-sales service to ensure customers experience no issues during use.

Comprehensive quality inspection reports for 5049 aluminum tube

- Ultrasonic Testing: Ensures no internal defects.

- Chemical Composition Analysis: Complies with industry standards.

- Mechanical Performance Testing: Verifies the strength of the product.

- Non-Destructive Testing: Comprehensive inspection for potential issues.

- Appearance Inspection: Ensures superior quality.

- Traceability Records: Full traceability throughout the process.

Packaging and shipping of 5049 aluminum tube

We provide professional packaging and shipping services for 5049 aluminum tube, ensuring safe and intact delivery.

We use high-quality packaging materials, such as fumigated wooden boxes and pallets, to effectively prevent moisture, corrosion, or damage during transportation.

Based on customer requirements, we offer flexible shipping methods, including sea freight, air freight, and land transport.

We also provide customized container loading plans based on the size and weight of the goods, maximizing space utilization and reducing logistics costs.

Whether it's a small or large order, we ensure timely delivery to meet your project needs.

Related products of 5049 aluminum tube