5754 aluminum performs well in marine and offshore environments due to its excellent corrosion resistance, especially in the atmosphere and seawater. It remains stable under a wide range of temperature conditions, exhibiting high strength and natural flexibility.

Although it is not possible to improve the performance through heat treatment, its good weldability and mechanical properties make it widely used in many fields. In addition, 5754 aluminum alloy is also very suitable for decorative anodizing because of its excellent anodizing properties.

MASTAR 5754 aluminum tube product introduction

Stock product types: 5754 cold drawn tube; 5754 extruded tube; 5754 round tube; 5754 square tube

Schedule: SCH20, SCH30, SCH40, STD, SCH80, XS, SCH60, SCH80, SCH120, SCH140, SCH160, XXS

Length: Can be cut to any length.

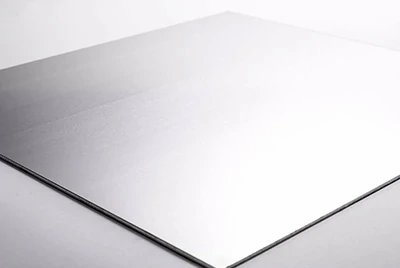

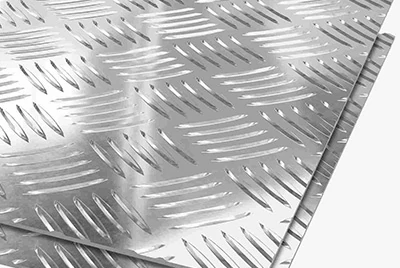

Surface treatment: anodizing, bright surface, black, polished ...

Aluminum tube ends: flat end, bevel end, threaded end

5754 Aluminum Equivalent Name

| 5754 Aluminum Equivalent Name | |||||

| UNS | EN | DIN | ISO | USA | WN |

| A95754 | EN AW-5754 | AlMg3 | AlMg3 | AA5754 | 3.3535 |

5754 cold drawn aluminum tube

- 5754 aluminum cold drawn tube is processed by cold working process, with high surface finish and excellent dimensional accuracy, while maintaining the good corrosion resistance and moderate strength of aluminum alloy. This kind of tube is suitable for fields with high requirements on appearance or precise matching, such as pipeline systems or precision mechanical parts in automobile manufacturing.

| 5754 Cold Drawn Tube Mechanical Properties Reference Table | ||||||||

| Temper | Dimensions | Yield strength | Tensile strength | Elongation | Hardness | |||

| D | S | T | Rp0,2 | Rm | A 50 | A | ||

| mm | mm | mm | [N/mm] | [N/mm] | [%] | [%] | HBW | |

| O/H111 | ≤80 | ≤60 | ≤20 | ≥80 | 180-250 | ≥14 | ≥16 | 45 |

| H14, H24, H34 | ≤25 | ≤5 | ≤10 | ≥180 | 240-290 | ≥3 | ≥4 | 75 |

| H18, H28, H38 | ≤10 | ≤3 | ≤3 | ≥240 | ≥280 | ≥2 | ≥3 | 88 |

5754 extruded aluminum tube

- 5754 aluminum extruded tube is formed by high temperature extrusion process, with good toughness and processability, and can produce large size and complex cross-section structural parts. Extruded tube is suitable for structures with high load requirements, such as ships, chemical equipment and building supports, giving full play to the corrosion resistance and wear resistance of 5754 aluminum alloy.

| 5754 Extruded Tube Mechanical Properties Reference Table | ||||||||

| Temper | Dimensions | Yield strength | Tensile strength | Elongation | Hardness | |||

| D | S | T | Rp0,2 | Rm | A 50 | A | ||

| mm | mm | mm | [N/mm] | [N/mm] | [%] | [%] | HBW | |

| F, H112 | ≤ 150 150 < D ≤ 250 | ≤ 150 150 < D ≤ 250 | ≤ 25 - | ≥ 80 ≥ 70 | ≥ 180 ≥ 180 | ≥ 12 - | ≥ 14 ≥ 13 | 47 |

| O, H111 | ≤150 | ≤150 | ≤25 | ≥80 | 180-250 | ≥15 | ≥17 | 45 |

5754 aluminum round tube

- Size range: 1-10 Wall thickness range: 0.125-0.75

- 5754 round pipe is particularly suitable for use in pipeline systems due to its corrosion resistance, especially in marine or chemical liquid transportation. Its round structure can evenly distribute internal pressure and reduce stress concentration.

- Marine equipment pipeline

- Hydraulic system

- Automobile oil pipe

- Air conditioning pipeline

5754 aluminum square tube

- Size range: 1-8 Wall thickness range: 0.125-0.5

- 5754 exhibits higher mechanical properties among non-heat-treatable alloys, with better bending and torsion resistance, making it suitable for use as load-bearing structures or frames. Its shape performs well in situations where stability and durability are required, such as building frames, railings and equipment brackets, and can provide higher structural strength.

- Building Frame

- Railing structure

- Transport equipment frame

- Industrial Equipment Brackets

Mastar's versatile manufacturing capabilities & shape customization

- MASTAR offers both cold drawn and extruded 5754 aluminum tubes, supporting flexible customization in wall thickness—from thin-wall to thick-wall—as well as length, end type, and tolerance control.

- We supply a wide range of shapes such as round, square, rectangular, flat, hex, corrugated, and coil tubes, meeting structural, flow, or decorative needs.

- To support piping systems, we also offer pipe bends, reducers, and tee fittings, ensuring reliable connections.

- Surface finishes include anodized tubes in silver, black, or custom colors. For ventilation or screening, perforated tubes are also available.

With diverse shapes and processes in one place, MASTAR is your reliable aluminum tube supplier for both standard and custom applications.

5754 aluminum tube chemical composition

| 5754 ( AlCu4MgSi, A95754 ) aluminum tube chemical composition reference table | |

| Aluminum (Al) | 94.2 to 97.4 |

| Magnesium (Mg) | 2.6 to 3.6 |

| Manganese (Mn) | 0 to 0.5 |

| Silicon (Si) | 0 to 0.4 |

| Iron (Fe) | 0 to 0.4 |

| Chromium (Cr) | 0 to 0.3 |

| Zinc (Zn) | 0 to 0.2 |

| Titanium (Ti) | 0 to 0.15 |

| Copper (Cu) | 0 to 0.1 |

| Residuals | 0 to 0.15 |

MASTAR marine grade 5754 aluminum tube corrosion resistance and weldability

One of the main features of 5754 aluminum alloy is its excellent corrosion resistance, especially in atmospheric and marine environments, and can effectively resist seawater corrosion. Another notable feature is its good weldability, which is compatible with a variety of processes and is suitable for applications requiring high-strength welding performance, such as marine engineering and automotive manufacturing.

- 5754 aluminum tube is known for its excellent corrosion resistance , especially in environments containing chlorides and salt water. 5754 aluminum rod can not only resist the erosion of seawater, but also maintain its mechanical properties and structural integrity for a long time in high humidity, salt spray and other harsh environmental conditions, ensuring the long-term reliability of the application.

- 5754 aluminum alloy has good welding properties and is very suitable for welding by conventional processes (MIG and TIG). AlMg3 [Al 5754] or AlMg5Mn [Al 5556A/Al 5556B] are recommended as welding filler metals. In the annealed condition, some difficulties may occur during machining (such as strip or thread chips). Machinability increases with increasing strain hardening.

MASTAR 5754 other hot products & related alloy recommendations

For similar requirements in marine, automotive, or architectural applications, you may also consider:

5052 aluminum: offering better formability and machinability for structural and piping systems

5083 aluminum: with higher strength and corrosion resistance, ideal for shipbuilding and pressure vessels

5154 aluminum: balancing weldability and seawater resistance, well-suited for offshore and marine projects

Why MASTAR is the preferred supplier of 5754 aluminum tube

- Fast Delivery: We have abundant inventory to ensure fast shipment of any product, saving time for your project.

- Customized service: MASTAR can provide customized service according to customer needs. You only need to inform the length, quantity, surface finish, cutting, bending, color coating, welding, end use and other special requirements.

- Competitive Price: Our products are priced competitively and we offer reasonable discounts for large quantities, giving you better prices and quality service.

- After-sales support: We provide fast after-sales support to ensure that you get timely help and support when using our products.