7005 aluminum alloy bar is a medium-high strength Al-Zn-Mg series aluminum alloy, combining excellent corrosion resistance and outstanding weldability. It can be further strengthened through heat treatment and offers superior fatigue resistance and lightweight advantages, making it popular in bicycle frames, sports equipment, rail transportation, and aerospace fields. Compared to other high-strength aluminum alloys, 7005 not only provides higher strength but also enhanced fatigue performance and workability, ideal for lightweight and durable industrial and structural applications.

Click to view the 7005 aluminum bar product guide

Msatar supplies various bar processing options, including extruded bars and cast billets, with the following specifications and size ranges:

- 7005 extrusion aluminum bar

- Tempers: O,T5,T6,T53

- DIA: 0.4"-16"(10-420mm)

- Spec: EN 755,EN 573

- 7005 aluminum cast billets bar

- Tempers: F

- DIA: 4.8"-53"(124-1350mm)

- Material used for subsequent extrusion production

Popular products of 7005 aluminum bar

7005 Aluminum Round Bar

- The 7005 aluminum round bar offers exceptional strength and fatigue resistance, making it widely used in high-load-bearing structures. Its excellent corrosion resistance and weldability make it suitable for outdoor and harsh environments.

Hot-Selling Sizes of 7005 Aluminum Round Bar

| Description | Diameter (in) | Diameter (mm) | Spec |

| 7005 Aluminum Round Bar | 0.75" | 19.05 | EN 755, ASTM B221 |

| 7005 Aluminum Round Bar | 1.0" | 25.4 | EN 755, ASTM B221 |

| 7005 Aluminum Round Bar | 1.25" | 31.75 | EN 755, ASTM B221 |

| 7005 Aluminum Round Bar | 1.5" | 38.1 | EN 755, ASTM B221 |

| 7005 Aluminum Round Bar | 1.75" | 44.45 | EN 755, ASTM B221 |

| 7005 Aluminum Round Bar | 2.0" | 50.8 | EN 755, ASTM B221 |

| 7005 Aluminum Round Bar | 2.25" | 57.15 | EN 755, ASTM B221 |

| 7005 Aluminum Round Bar | 2.5" | 63.5 | EN 755, ASTM B221 |

| 7005 Aluminum Round Bar | 2.75" | 69.85 | EN 755, ASTM B221 |

| 7005 Aluminum Round Bar | 3.0" | 76.2 | EN 755, ASTM B221 |

| 7005 Aluminum Round Bar | 3.5" | 88.9 | EN 755, ASTM B221 |

| 7005 Aluminum Round Bar | 4.0" | 101.6 | EN 755, ASTM B221 |

| 7005 Aluminum Round Bar | 5.0" | 127 | EN 755, ASTM B221 |

| 7005 Aluminum Round Bar | 6.0" | 152.4 | EN 755, ASTM B221 |

| 7005 Aluminum Round Bar | 7.0" | 177.8 | EN 755, ASTM B221 |

| 7005 Aluminum Round Bar | 8.0" | 203.2 | EN 755, ASTM B221 |

Click to see all

Click to see all 7005 Aluminum Flat Bar

- Size: 5-200mm

- Known for its high strength and lightweight properties, the 7005 aluminum flat bar is ideal for use in construction and machinery manufacturing where flat support and frame structures are needed. Its superior fatigue resistance and machinability make it a top choice for a wide range of industrial applications.

| Description | Thickness/mm | Width/mm | Spec |

| 7005 aluminum flat bar | 5 | 10/20/30/40 | EN 755, ASTM B221 |

| 7005 aluminum flat bar | 10 | 20/30/40/50/60 | EN 755, ASTM B221 |

| 7005 aluminum flat bar | 15 | 20/30/40/50/60 | EN 755, ASTM B221 |

| 7005 aluminum flat bar | 20 | 30/40/50/60/70 | EN 755, ASTM B221 |

| 7005 aluminum flat bar | 30 | 40/50/60/70/80 | EN 755, ASTM B221 |

| 7005 aluminum flat bar | 40 | 50/60/70/80/90 | EN 755, ASTM B221 |

| 7005 aluminum flat bar | 50 | 60/70/80/90/100 | EN 755, ASTM B221 |

| 7005 aluminum flat bar | 60 | 70/80/90/100/110 | EN 755, ASTM B221 |

| 7005 aluminum flat bar | 70 | 80/90/100/110/120 | EN 755, ASTM B221 |

| 7005 aluminum flat bar | 80 | 90/100/110/120/130 | EN 755, ASTM B221 |

| 7005 aluminum flat bar | 90 | 100/110/120/130/140 | EN 755, ASTM B221 |

| 7005 aluminum flat bar | 100 | 110/120/130/140/150 | EN 755, ASTM B221 |

| 7005 aluminum flat bar | 110 | 120/130/140/150/160 | EN 755, ASTM B221 |

| 7005 aluminum flat bar | 120 | 130/140/150/160/170 | EN 755, ASTM B221 |

| 7005 aluminum flat bar | 130 | 140/150/160/170/180 | EN 755,ASTM B221 |

| 7005 aluminum flat bar | 140 | 150/160/170/180/190 | EN 755,ASTM B221 |

| 7005 aluminum flat bar | 150 | 160/170/180/190/200 | EN 755,ASTM B221 |

Click to see all

Click to see all In addition to 7005 aluminum bars, Mastar also supplies a wide range of aluminum bar alloys in various shapes such as round bars, square bars, flat bars, and hex bars. If you are looking for alternatives with similar machinability or mechanical strength, feel free to explore our whole aluminum bar product pages or contact us for assistance.Quick Quote

Hot selling temper of 7005 aluminum bar

7005 T5 Aluminum Bar

7005 T5 Aluminum Bar- The 7005 T5 aluminum bar undergoes artificial aging treatment, providing high strength and excellent dimensional stability. It is commonly used in structural components that require high strength and good machinability, such as in transportation equipment and sports gear.

7005 T53 Aluminum Bar

7005 T53 Aluminum Bar- The T53 temper is a specific heat-treated condition for 7005 aluminum, offering high fatigue strength (170 MPa) and a solid strength-to-weight ratio, with a tensile strength reaching up to 390 MPa. Although it has lower ductility, its strength and fatigue resistance make it ideal for applications with high stress and repetitive loads, such as sports equipment and structural components.

7005 T6 Aluminum Bar

7005 T6 Aluminum Bar- 7005 T6 aluminum is one of the most common heat-treated variations of this alloy. The "T6" temper is a hardening process that enhances mechanical properties for greater strength and durability, making it especially suitable for applications where improved strength is essential, such as bicycle frames and sports equipment made from 7005 aluminum alloy.

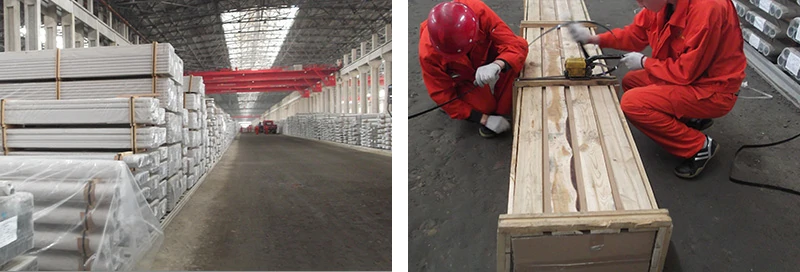

What we provide as a high-quality aluminum bar supplier

- Premium Products: Using high-quality aluminum billets and precise alloying and heat treatment processes, we optimize strength and ductility, ensuring uniform cooling and annealing. This guarantees high tensile strength and excellent performance.

- Grain Control: Produced through reverse extrusion, our aluminum bars have controlled cooling rates and homogenization treatment, maintaining grain size at ≤0.5mm to minimize quality defects, enhance material consistency, and refine microstructure.

- Timely Delivery: With a 10,000-ton inventory, standard sizes are ready for immediate dispatch. Advanced equipment and a skilled team ensure fast production cycles and reliable logistics for on-time delivery.

- Competitive Pricing: We support both retail and bulk procurement for metal distributors, offering discounts and rebate policies for B2B customers. Transparent pricing ensures our aluminum bar quality comes at a price advantage.

- Comprehensive Quality Testing: We implement strict multi-step testing, including tensile strength, elongation, ultrasonic testing, and metallographic inspection, ensuring that our aluminum bars meet AMS, EN, and NADCAP standards.

- Customer Service: We provide complete after-sales support, addressing customer concerns with an experienced technical team offering professional advice and guidance, and an established customer service system to guarantee an exceptional service experience.

Features of 7005 aluminum bar

- Exceptional Weldability: The 7005 aluminum alloy resists cracking during welding and retains high strength after welding, ideal for structural components requiring robust connections.

- Medium-High Strength: With a tensile strength of up to 350 MPa, 7005 aluminum alloy combines strength and workability, making it suitable for high-strength applications.

- Fatigue Resistance: The 7005 alloy offers excellent fatigue performance, maintaining structural stability under repeated loading without fatigue failure.

- Corrosion Resistance: Known for outstanding corrosion resistance, it withstands humidity and salt, extending the material's service life.

- Stress Corrosion Cracking Resistance: This alloy maintains stability even under high stress and harsh conditions, resisting stress corrosion cracking effectively.

- Good Machinability: 7005 aluminum is easy to process through extrusion, welding, cutting, and more, showcasing adaptable machining capabilities.

Best applications for 7005 aluminum bar

Bicycle Manufacturing

Bicycle Manufacturing- Due to its high strength, corrosion resistance, and lightweight properties, 7005 aluminum alloy is the preferred choice for high-end bicycle brands like Motobecane and Kinesis. Frames and beams made from 7005 aluminum provide excellent impact resistance, delivering a superior riding experience on rough terrain.

Outdoor Sports Equipment

Outdoor Sports Equipment- In outdoor sports, 7005 aluminum alloy stands out for its strength-to-weight ratio and weldability. Beyond bike frames, it is used for aluminum tent poles, tennis rackets, softball bats, golf clubs, and trekking poles.

Transportation

Transportation- With its strength, lightweight nature, and corrosion resistance, 7005 aluminum is widely applied in transportation for trusses, rods, support structures, automotive crash beams, truck reinforcements, trailers, containers, and rapid transit vehicles. This improves vehicle stability, transport efficiency, and fuel economy.

Railway Transportation

Railway Transportation- 7005 aluminum's excellent weldability, fatigue resistance, and corrosion resistance make it ideal for railway applications. It's commonly used in high-speed train body structures, pillow beams, and other high-stress components.

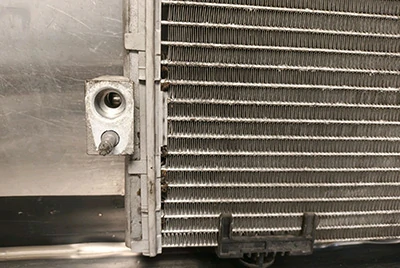

Large Heat Sinks

Large Heat Sinks- 7005 aluminum is well-suited for medium-strength, high-toughness large heat sinks and heat exchanger components, particularly where post-weld heat treatment is not possible. Its natural strength and corrosion resistance make it ideal for high-temperature, high-stress parts, ensuring heat dissipation efficiency and durability.

Military Equipment

Military Equipment- In the military sector, 7005 aluminum alloy is extensively used, especially in rocket launch tubes and missile tail fins. Its high strength, corrosion resistance, and resistance to stress corrosion cracking make it the ideal material for these demanding applications.

7005 aluminum bar procurement guide

1.Comprehensive documentation

Msatar can provide detailed quality testing reports, including raw material certificates, laboratory test reports, fumigation reports, specification guides, commercial invoices, and guarantees, ensuring the quality transparency and traceability of each batch of products.

2.Fine export packaging

In international shipping, the quality of packaging directly affects whether goods can rust, corrode, scratch, deform, or suffer other damages during transport. Therefore, high-quality packaging materials are crucial. Msatar has years of export packaging experience, providing safe and reliable packaging solutions for thousands of businesses. By using fumigated wooden boxes, wooden pallets, and other high-quality packaging materials, our packaging damage rate is only one-third of the industry average.

3.Professional loading solutions

Our experienced order-following team can provide flexible and diverse loading solutions, including options for 20/40-foot containers or bulk ships. Regardless of your cargo specifications and shapes, we can customize a refined loading plan that saves an average of 15% container space, effectively reducing your logistics costs.

4. Alternative alloy options for flexible sourcing

Depending on your specific application and processing requirements, Mastar also offers a range of related aluminum bar alloys that serve as alternatives or complements to 7005. These include high-strength options like 7003 and 7021 for structural components, as well as 6061 and 6082 for better weldability and general-purpose machining. By consulting with our technical team, you can select the most suitable alloy to optimize your material performance and cost efficiency.

Knowledge center for 7005 aluminum bar

Specification of 7005 aluminum bar

- EN 573-3: 2009 Aluminium and aluminium alloys. Chemical composition and form of wrought products. Chemical composition and form of products

- EN 755-2: 2008 Aluminium and aluminium alloys. Extruded rod/bar, tube and profiles. Mechanical properties

- ASTM B221: Aluminum and Aluminum-Alloy Extruded Bars, Rods, Wire, Profiles, and Tubes

Chemical composition of 7005 aluminum bar

| Element | Value |

| Si | 0.35 |

| Fe | 0.40 |

| Cu | 0.10 |

| Mn | 0.2-0.7 |

| Mg | 1.0-1.8 |

| Cr | 0.06-0.20 |

| Zn | 4.0-5.0 |

| Ti | 0.01-0.06 |

| Remarks | 0.08-0.20 Zr |

| Others (Each) | 0.05 |

| Others (Total) | 0.15 |

| Al | Rem |

The zinc and magnesium content in 7005 aluminum alloy gives it high strength, suitable for structural applications that need to withstand high loads while maintaining good welding performance.

Physical properties of 7005 aluminum bar

| Properties | value |

| Density | 2.78 g/cm³ |

| Melting point | 610 - 640°C |

| Thermal conductivity | 160 W/m·K |

| Coefficient of thermal expansion | 23.1 µm/m·°C |

| Electrical conductivity | 33 % IACS |

7005 aluminum alloy has a low density and is not easy to rust, making it particularly suitable for industries with high requirements on weight and corrosion resistance, such as bicycle frames and shipbuilding.

Mechanical properties of 7005 aluminum bar

| Properties | value |

| Tensile strength Rm/Mpa | 340-350 |

| Yield strength Rp0.2/Mpa | 270-290 |

| Elongation | 8-10% |

| Hardness | 110 |

The strength of 7005 aluminum alloy makes it an ideal structural material, particularly suitable for components that need to withstand impact and fatigue loads, such as bicycle frames, transportation equipment and building structures.

7005 vs. 7075 aluminum comparison

| Properties | 7005 | 7075 |

| Main alloying elements | Zinc (Zn), Magnesium (Mg) | Zinc (Zn), Magnesium (Mg), Copper (Cu) |

| Tensile strength | 290-350 MPa | 510-600 MPa |

| Weldability | Excellent | Poor |

| Processability | Good | Difficult |

| Corrosion resistance | Excellent | Poor |

| Density | 2.78 g/cm³ | 2.81 g/cm³ |

| Hardness | 94 | 150 |

- Strength/Weldability: 7075 aluminum is stronger but has lower weldability, prone to cracking. 7005 aluminum offers excellent weldability while maintaining high strength, ideal for applications requiring strong welded connections like bicycle frames.

- Machinability: 7075 aluminum has higher hardness, making it challenging to machine, whereas 7005 aluminum offers better machinability for complex profile designs.

- Corrosion Resistance: 7005 aluminum is more corrosion-resistant, suitable for outdoor and humid environments, while 7075 performs poorly in corrosive settings.

- Cost: With lower zinc content, 7005 aluminum is more affordable, providing a cost advantage over 7075.

In summary, 7075 aluminum excels in extreme high-stress environments with its superior strength and hardness but lacks in weldability and corrosion resistance. 7005 aluminum is favored for lightweight applications with its weldability, corrosion resistance, and cost-efficiency, particularly in bicycle frames and building structures.

7005 vs. 6061 aluminum comparison

| Properties | 7005 | 6061 |

| Main alloying elements | Zinc (Zn), Magnesium (Mg) | Magnesium (Mg), Silicon (Si) |

| Tensile strength | 290-350 MPa | 240-310 MPa |

| Weldability | Good | Excellent |

| Processability | Difficult | Excellent |

| Corrosion resistance | Excellent | Fine |

- Strength: 7005 aluminum has greater strength, ideal for applications requiring high load-bearing, such as bicycle frames and heavy transport equipment. 6061 aluminum provides adequate strength for many industrial uses.

- Weldability & Machinability: With magnesium and silicon content, 6061 aluminum offers superior weldability and machinability. Although 7005 aluminum requires post-weld heat treatment for strength recovery, it welds better than 7075.

- Lightweight Design: 7005 aluminum's high strength allows for thinner tubing, making it excellent for weight-sensitive designs like bike frames. While heavier, 6061 aluminum has a good strength-to-weight ratio for general industrial use.

- Cost: 7005 aluminum has higher production costs due to zinc content and processing complexity, whereas 6061 aluminum is cost-effective for high-volume industrial production.

In conclusion, 7005 aluminum outperforms in strength and lightweight design but has higher processing costs, suitable for high-strength, high-load applications. 6061 aluminum offers versatility with excellent machinability and lower costs, commonly used in construction and industrial equipment.

Why 7005 aluminum alloy is ideal for bicycle frames

7005 aluminum alloy is perfect for bicycle frames due to its high strength and lightweight properties, allowing for thinner tubing designs and reduced frame weight—essential for speed and endurance cycling. Additionally, 7005 aluminum is highly corrosion-resistant, ideal for use in wet and muddy environments with lower maintenance. Its weldability provides design flexibility, accommodating complex structures and custom designs.

Mastar also supplies 7005 aluminum tubes in various sizes and tempers, making it easy to meet the structural and aesthetic needs of custom frame manufacturing.

Why 7005 aluminum bar is suitable for rail transportation

In rail transportation, 7005 aluminum alloy is ideal for high-speed train bodies, particularly where high strength, durability, and weldability are essential.

1.Outstanding Weldability: With excellent weldability, 7005 aluminum meets the demanding welding needs of complex train body structures. It resists cracking and maintains high weld seam strength, ensuring structural integrity and safety during high-speed operations.

2.Lightweight Design: The low density (2.78 g/cm³) of 7005 aluminum supports lightweight rail designs, improving energy efficiency and reducing fuel or power consumption. Compared to traditional steel, it reduces the overall weight while maintaining the required strength.

3.Fatigue Resistance: High-speed trains face constant load changes, and 7005 aluminum's fatigue strength (150 MPa) maintains stability under sustained pressure and vibration. This durability extends the lifespan of critical components like the body frame and bolster beam, enhancing operational safety.

4.Corrosion Resistance: Operating in diverse climates and saline environments, 7005 aluminum provides excellent corrosion resistance, reducing oxidation and aging. This durability lowers maintenance needs and supports reliable train performance throughout its service life.

Click to collapse

Click to collapse