The 7003 Aluminum Bar is a high-strength aluminum-zinc alloy bar with exceptional mechanical properties and corrosion resistance, making it suitable for use in automotive, aerospace, and structural applications.

As an Al-Zn-Mg-Zr series alloy, 7003 aluminum alloy excels in applications requiring structural components and lightweight solutions, particularly for manufacturing vehicle chassis, frames, and aircraft structures. When facing heavy loads and harsh environmental conditions, 7003 alloy provides an ideal solution for various industrial applications due to its high strength, good machinability, and superior corrosion resistance.

Click to view the 7003 Aluminum Bar product guide

Msatar offers a range of processed bars, including extruded bars and cast bar stock, with specific size ranges as follows:

- 7003 extrusion aluminum bar

- Temper: T5,T6

- DIA: 0.4"-16"(10-420mm)

- Spec: EN 755,EN 573

- 7003 aluminum cast billets bar

- Temper: F

- DIA: 4.8"-53"(124-1350mm)

- Material used for subsequent extrusion production

Popular products of 7003 aluminum bar

The 7003 Aluminum Bar offers a wide range of product categories to meet the diverse needs of different industries. Common product forms include:

7003 aluminum Round Bar

DIA: 5-420mm

Ideal for applications requiring high strength and lightweight characteristics, such as automotive frames and aerospace structural components.

7003 aluminum Square Bar

Size: 5-200mm

Commonly used in construction and industrial structures, providing enhanced strength and support.

7003 aluminum Round Bar

7003 aluminum Flat Bar

Provides good strength and flexibility, making it suitable for manufacturing aerospace components and heavy machinery structures.

7003 aluminum Hex Bar

Size: 5-200mm

Highly popular in the manufacturing of high-precision parts like bolts and fasteners, especially those needing corrosion resistance and high strength.

7003 T5 aluminum Bar

The material is artificially aged, offering moderate strength while being easier to machine and weld, suitable for scenarios requiring complex machining and welding.

7003 T6 aluminum Bar

The material undergoes solution heat treatment and artificial aging, resulting in significant improvements in strength and hardness, making it ideal for applications requiring extremely high strength and wear resistance.

In addition to 7003 aluminum bars, Mastar also supplies a wide range of aluminum bar alloys in various shapes such as round bars, square bars, flat bars, and hex bars. If you are looking for alternatives with similar machinability or mechanical strength, feel free to explore our whole aluminum bar product pages or contact us for assistance.Quick Quote

What can we provide as a high-quality aluminum bar supplier?

- High-Quality Products: We use high-quality aluminum bar billets and precise alloy and heat treatment processes to optimize the product's strength and ductility, ensuring uniform cooling and annealing. This guarantees high tensile strength and excellent performance of the products.

- Good Roughness Control: By utilizing a reverse extrusion process, we control the cooling rate and homogenization treatment, keeping the roughness usually at ≤0.5mm. This reduces quality defects and ensures fine material structure, enhancing product consistency.

- Delivery Time: With a stock of tens of thousands of tons, we can quickly match standard sizes from existing inventory, ensuring fast shipping. Our advanced equipment and professional team shorten delivery times and provide convenient logistics for on-time delivery.

- Price Advantage: We support both retail and bulk purchasing for metal distributors, offering discounts and rebate policies for B2B bulk purchases. Our pricing is transparent, ensuring a competitive edge for the same quality of aluminum bars.

- Comprehensive Quality Testing: We strictly adhere to multiple inspection procedures, including tensile strength, elongation, ultrasonic testing, and metallographic testing, ensuring that our aluminum bars meet AMS, EN, and NADCAP certification standards.

- Customer Service: We provide comprehensive after-sales service to address customer concerns. Our experienced technical team offers professional consultation and guidance, establishing a robust customer service system to ensure a high-quality service experience.

Features of the 7003 aluminum bar

High Strength: 7003 is considered a high-strength material in the aluminum alloy series, making it particularly suitable for heavy-load structural components.

High Ductility and Formability: 7003 exhibits excellent ductility, reducing the risk of cracking and damage during the machining process.

Excellent Corrosion Resistance: 7003 aluminum alloy demonstrates good corrosion resistance in humid and salt-spray environments, making it suitable for outdoor or marine applications.

Good Machinability: 7003 aluminum alloy can be precisely manufactured using various processes such as extrusion, cutting, and stamping, and is easy to weld.

Lightweight Design: The low-density characteristics of 7003 aluminum alloy provide a significant advantage in applications requiring weight reduction, such as in the automotive and aerospace industries.

Stability in High and Low Temperature Environments: 7003 aluminum alloy maintains its physical and mechanical properties across various temperature ranges, suitable for applications that require resistance to high or extreme low temperatures.

Best applications for 7003 aluminum bar

Automotive Industry

Automotive Industry- The 7003 aluminum alloy, with its perfect combination of strength and lightweight properties, is widely used in automotive chassis, body frames, and suspension systems. For example, roof supports, crash beams, and door frames effectively reduce vehicle weight while ensuring strength and safety.

Aerospace Industry

Aerospace Industry- The 7003 aluminum alloy boasts an excellent strength-to-weight ratio, making it widely used in aircraft wings, tail surfaces, and other critical structural components. This ensures structural strength while reducing overall weight, thereby improving fuel efficiency and flight performance.

Building and Industrial Structures

Building and Industrial Structures- Due to its outstanding corrosion resistance and weatherability, 7003 aluminum alloy is suitable for structural components exposed outdoors for extended periods. This alloy is commonly used in bridges, support beams, railings, and other load-bearing structures, particularly in corrosive environments such as marine, coastal, or acid rain areas.

Pressure Vessels and Marine Equipment

Pressure Vessels and Marine Equipment- 7003 aluminum is used in the manufacture of pressure vessels, gas storage tanks, and marine equipment due to its excellent corrosion resistance and high strength. In the marine industry, where materials are in prolonged contact with seawater, the corrosion resistance of 7003 alloy ensures equipment durability and reduces maintenance costs.

7003 aluminum bar procurement guide

1. comprehensive documentation

Msatar provides detailed quality testing reports, including raw material certificates, laboratory test reports, fumigation reports, specification guides, commercial invoices, and guarantees, ensuring transparency and traceability of each batch of products.

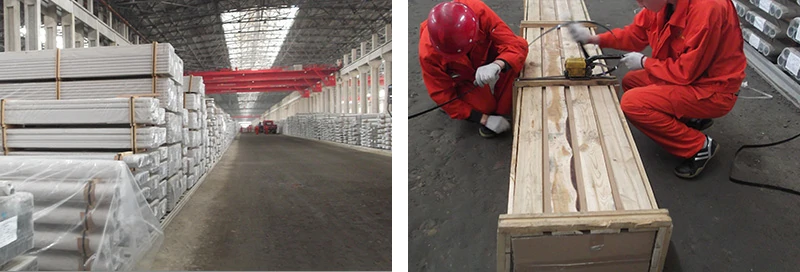

2. precision export packaging

In international shipping, the quality of packaging materials directly affects whether goods become rusty, corroded, scratched, deformed, or damaged during transit. Therefore, high-quality packaging materials are crucial. Msatar has years of experience in export packaging, providing safe and reliable solutions for thousands of companies. By using fumigated wooden boxes, wooden pallets, and other quality materials, our packaging damage rate is only one-third of the industry average.

3.professional loading solutions

Our experienced team offers flexible and diverse loading solutions, with options for 20-foot or 40-foot containers or bulk shipping. Regardless of the size or shape of your cargo, we can customize a precise loading plan, saving an average of 15% in container space, thereby reducing your logistics costs.

Knowledge center for 7003 aluminum bar

Standards and specifications of 7003 aluminum bar

- EN 573-3: 2009 Aluminium and aluminium alloys. Chemical composition and form of wrought products. Chemical composition and form of products

- EN 755-2: 2008 Aluminium and aluminium alloys. Extruded rod/bar, tube and profiles. Mechanical properties

Chemical composition of 7003 aluminum bar

| Element | Value |

| Si | 0.12 |

| Fe | 0.15 |

| Cu | 1.9-2.5 |

| Mn | 0.1 |

| Mg | 2.0-2.7 |

| Cr | 0.04 |

| Zn | 5.9-6.9 |

| Ti | 0.06 |

| Remarks | 0.08-0.15 Zr |

| Others (Each) | 0.05 |

| Others (Total) | 0.15 |

| Al | Rem |

The zinc and magnesium content in 7003 aluminum provides high strength and good corrosion resistance. The trace addition of zirconium enhances the material's crack resistance and heat treatment effectiveness.

Physical properties of 7003 aluminum bar

| Properties | Value |

| Density | 2.80 g/cm³ |

| Melting point | 510 – 630°C |

| Thermal conductivity | 160 W/m·K |

| Coefficient of thermal expansion | 23.7 µm/m·°C |

| Electrical conductivity | 36 % IACS |

Its physical characteristics give 7003 alloy significant advantages in aerospace and automotive structures, especially in high-temperature environments, where the material demonstrates excellent stability and resistance to deformation.

Mechanical properties of 7003 aluminum bar

| Properties | T5 | T6 |

| Tensile strength Rm/Mpa | 310 | 350 |

| Yield strength Rp0.2/Mpa | 260 | 290 |

| Elongation | 8-10 % | 8-10% |

| Hardness | - | 110 |

7003 aluminum alloy exhibits outstanding mechanical properties, particularly under high strength and high ductility requirements. With its high tensile strength and good ductility, it provides structural support under high load conditions in industries such as automotive and aerospace.

7003 vs 7075 aluminum alloy

7003 and 7075 aluminum alloys are frequently compared in many high-strength applications. The key differences are:

| Properties | 7003 | 7075 |

| Main elements | Zn, Mg, Zr | Zn, Mg, Cu |

| Tensile strength | 390-500MPa | 510-600MPa |

| Corrosion resistance | Good | Poor |

| Application scenarios | Automobile, aerospace, construction | Aerospace, aerospace, high load applications |

7003 alloy has better corrosion resistance than 7075, making it particularly suitable for applications in humid or corrosive environments.

7075 alloy offers higher strength but is less corrosion-resistant than 7003, thus it is often used in high-stress but relatively dry environments.

7003 vs 6061 aluminum alloy

There are also differences in processability and applications between 7003 and 6061 aluminum alloys:

| Properties | 7003 | 6061 |

| Main elements | Zn, Mg, Zr | Mg, Si |

| Tensile strength | 390-500MPa | 240-310MPa |

| Weldability | Good | Very good |

| Processability | Good | Very good |

| Application scenarios | Automobile, aerospace, construction | Architecture, structure, general industry |

6061 alloy is better suited for general industrial applications due to its excellent welding and machining properties, making it ideal for mass production.

7003 alloy, with its higher strength, performs better in high-load structures, particularly in automotive and aerospace sectors.

7003 vs 7005 aluminum alloy

7003 and 7005 aluminum alloys are both high-strength materials in the 7xxx series, but they differ in weldability, post-weld strength, and application focus:

| Properties | 7003 | 7005 |

| Main elements | Zn, Mg, Zr | Zn, Mg, Mn, Cu |

| Tensile strength | 390–500MPa | 410–530MPa |

| Weldability | Good | Excellent |

| Post-weld strength | Moderate | Higher (T5/T6 options) |

| Application scenarios | Rail transit, bicycle, structural frames | Bicycle, tent poles, train structures |

7005 alloy provides higher strength and better post-weld performance, making it ideal for welded lightweight structures like bicycle frames and railway profiles.

7003 alloy offers a good balance of strength and corrosion resistance, often used in structural components that require simple processing and high fatigue resistance.

Why is 7003 aluminum alloy ideal for the automotive manufacturing industry?

7003 aluminum alloy plays a crucial role in the automotive manufacturing industry because it combines lightweight, high strength, and corrosion resistance, meeting modern vehicles' high standards for safety, fuel efficiency, and environmental sustainability. Key reasons for its suitability include:

1. Perfect Combination of High Strength and Lightweight Design

7003 aluminum alloy is a high-strength aluminum alloy with tensile and yield strengths significantly higher than common automotive structural materials. This makes it suitable for manufacturing vehicle frames, chassis, door beams, and roof support structures that endure substantial impacts and loads. Additionally, the alloy's low density (about one-third that of steel) significantly reduces vehicle weight, helping manufacturers enhance fuel efficiency and reduce carbon emissions without compromising safety.

2. Excellent Corrosion Resistance

Vehicles often operate in harsh environments, such as humid climates and salt-laden roads. 7003 aluminum alloy exhibits outstanding corrosion resistance, effectively extending the service life of automotive components and reducing maintenance costs, especially in coastal or rainy regions.

3. Good Workability and Weldability

7003 aluminum alloy has good machining properties in both T5 and T6 conditions, accommodating complex forming processes such as extrusion, cutting, and stamping. Its weldability is also excellent, particularly in the T5 condition, where high-quality welds can be achieved with minimal cracking during welding. This is crucial for manufacturing structural components of vehicles, ensuring the strength and reliability of critical parts.

4. Enhanced Safety Performance

The high strength and ductility of 7003 aluminum alloy provide excellent energy absorption capabilities during collisions. When used in vehicle body structures, it can better absorb and distribute impact forces, reducing injuries to occupants. This high safety characteristic meets the stringent safety requirements in modern automotive manufacturing and is a significant reason for its widespread application in crash beams and frame components.

5. Adaptation to the Development Needs of New Energy and Electric Vehicles

With the rapid development of electric and new energy vehicles, lightweight body structures have become increasingly important. 7003 aluminum alloy not only helps reduce vehicle weight, extending the range of electric vehicles but also enhances the structural strength of components like battery supports, ensuring battery safety.

Other Recommended Aluminum Alloys for Automotive Manufacturing

While 7003 aluminum alloy offers an excellent balance of strength, weight, and corrosion resistance for automotive structural parts, Mastar also supplies a variety of other aluminum alloys tailored to different performance and processing needs in the automotive industry:

6061 aluminum alloy – Known for its outstanding weldability and general structural strength, 6061 is widely used in vehicle chassis components, brackets, and suspension parts that require both formability and durability.

6082 aluminum alloy – A high-strength alloy with excellent corrosion resistance, often used in commercial vehicle frames and trailer structures where both toughness and long service life are required.

6016 aluminum alloy – Frequently used in automotive body panels and inner car door parts due to its excellent surface quality and formability, especially after paint baking.

7021 aluminum alloy – Offers high strength and dimensional stability, making it suitable for forged suspension arms, wheel carriers, and other safety-critical forged parts.

5754 aluminum alloy – Provides excellent corrosion resistance and moderate strength, ideal for interior parts, fuel tanks, and car body panels exposed to corrosive environments.

Mastar's comprehensive range of automotive-grade aluminum alloys ensures optimal material selection for every component—whether it's for EV battery enclosures, structural reinforcements, or lightweight body panels.