5A02 aluminum bar stock size

| Alloy | Temper | Diameter (mm) | Length (mm) |

| 5A02 | H112 | 50 | 1000-6000 |

| 5A02 | H112 | 60 | 1000-6000 |

| 5A02 | H112 | 80 | 1000-6000 |

| 5A02 | H112 | 100 | 1000-6000 |

| 5A02 | H112 | 120 | 1000-6000 |

| 5A02 | H112 | 150 | 1000-6000 |

| 5A02 | H112 | 180 | 1000-6000 |

| 5A02 | H112 | 200 | 1000-6000 |

| 5A02 | H112 | 250 | 1000-6000 |

| 5A02 | H112 | 300 | 1000-6000 |

| 5A02 | H112 | 350 | 1000-6000 |

Product shapes & processing types of 5A02 aluminum bar

Mastar offers 5A02 aluminum bars in a variety of shapes and processing forms to suit different application needs. With excellent extrudability, weldability, and corrosion resistance, 5A02 is ideal for both structural and precision-machined components. Quick Quote

Available Shapes:

- Round Bar – Most commonly used form, suitable for shafts, pins, supports, and general structural parts.

- Square Bar – Ideal for frames, fixtures, and parts requiring flat edges and angular stability.

- Flat Bar – Suitable for brackets, stiffeners, and pressure-bearing components.

- Custom Extruded Profiles – Tailored cross-sectional shapes can be produced upon request for specialized uses.

Processing Methods:

- Extruded Bar – Excellent surface quality and dimensional consistency, ideal for long-length or complex shapes.

- Cold Drawn Bar – Enhanced surface finish and dimensional precision, often used in CNC machining and precision parts.

- Forged Bar – Suitable for high-strength and corrosion-resistant applications, especially in marine and pressure vessel environments.

- Heat Treatment Options – Available in O and H112 tempers, with the potential for aging hardening to improve strength when needed.

Looking for more shapes or alloy options? Explore our aluminum bar product catalog for a wide selection of extruded, drawn, and forged bars across various grades.

Characteristics of 5A02 aluminum bar

- High strength, its yield strength is about 250 MPa, tensile strength is about 320 MPa, and elongation is above 12%. This good mechanical property makes it perform well in many applications.

- It has good corrosion resistance, especially in seawater environment. Therefore, it is widely used in ships, marine facilities and other fields, and can meet applications with high corrosion resistance requirements.

- It has good weldability. When conventional welding methods are used, such as argon arc welding, arc welding, etc., the welded joint has high strength and the welding process is relatively simple.

- It has good machinability and is suitable for various common processing methods, such as milling, drilling, turning, stretching, etc. At the same time, 5A02 alloy is also suitable for extrusion processing, and complex shapes can be obtained.

- It can be heat treated, such as aging hardening, to further improve its strength and hardness.

These combined characteristics make 5A02 aluminum bar a reliable choice for both structural and precision applications.If you are considering aluminum bars with similar strength and corrosion resistance, you may also explore our 5083 aluminum bar for marine-grade performance and 6061 aluminum bar for versatile mechanical and machining applications.

Chemical composition of 5A02 aluminum bar

| Element | Composition % |

| Al | Remainder |

| Si | ≤0.40 |

| Fe | ≤0.40 |

| Cu | ≤0.10 |

| Mn | 0.15-0.40 |

| Mg | 2.0-2.8 |

| Ti | ≤0.15 |

| Other(each) | ≤0.05 |

| Other(total) | ≤0.15 |

Mechanical properties of 5A02 aluminum bar

| Alloy | Temper | Diameter/mm | Tensile strength RmMPa | Elongation % |

| 5A02 | O, H112 | 25.00-150.00 | ≤225 | 10 |

Application fields of 5A02 aluminum bar

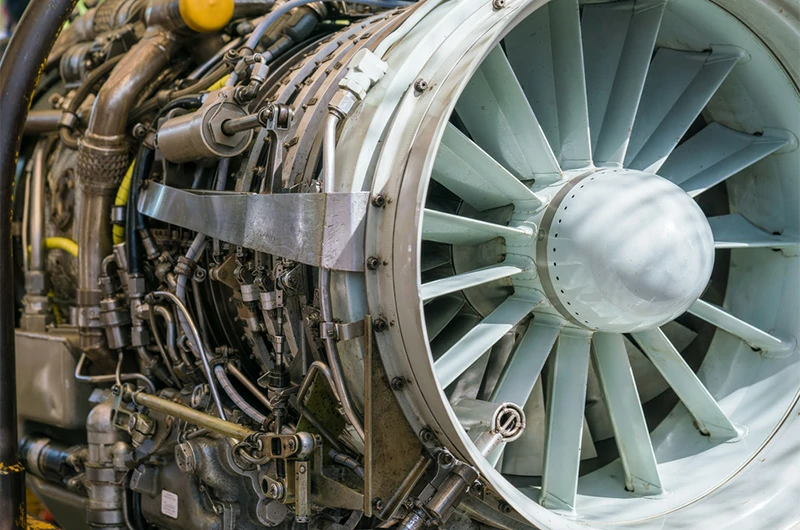

Aviation and aerospace: 5A02 aluminum alloy rods are used to manufacture aircraft structural parts because it can provide the necessary strength and corrosion resistance while ensuring lightweight.

Shipbuilding: In the shipbuilding industry, it is used to manufacture hulls, cabin linings, piping systems, etc. to resist seawater corrosion.

Pressure vessels: Due to its good corrosion resistance and weldability, 5A02 aluminum alloy rods are suitable for the manufacture of chemical equipment and pressure vessels.

Automotive industry: In the automotive manufacturing industry, it is used to manufacture automobile fuel tanks, fuel system components, radiators, etc.

Piping systems: In the oil and gas industry, it is used to manufacture pipes and fittings for conveying fluids.

Home appliances and refrigeration equipment: 5A02 aluminum alloy rods can also be used for internal structural parts of home appliances such as refrigerators and air conditioners, as well as parts of refrigeration equipment.

Construction industry: In construction, it is used to manufacture corrosion-resistant doors, windows, railings and decorative parts, etc.

Forging process of 5A02 aluminum bar

Raw material preparation: First, make sure that the raw material is a high-purity, defect-free 5A02 aluminum alloy ingot. These ingots may need to be preheated to make forging easier.

Heating: The aluminum alloy ingot is placed in a forging furnace for heating. The heating temperature is usually between 460℃ and 530℃, which can ensure that the alloy has good plasticity and reduce the difficulty of forging. Too high a temperature may cause excessive grain growth and affect the mechanical properties of the final product.

Forging process: The heated aluminum alloy ingot is forged on a forging machine. Forging can be done in a variety of ways, such as free forging, die forging or rotary forging, etc., and the appropriate forging method is selected according to the required shape and size. During the forging process, the appropriate forging speed and temperature should be maintained to prevent cracks and excessive deformation.

Intermediate annealing: During the forging process, intermediate annealing may be required to eliminate internal stress, restore the plasticity of the material, and facilitate subsequent forging operations. The annealing temperature is generally between 350℃ and 450℃, and it is slowly cooled after a period of heat preservation.

Final forging and forming: After the forging of the preliminary shape is completed, final forging is performed to obtain the desired final shape. This may include steps such as hammering, rolling or extrusion.

Cooling: After forging, the aluminum alloy should be cooled slowly to prevent stress and cracks caused by rapid cooling. Furnace cooling or air cooling can be used.

Post-processing: After forging, 5A02 aluminum alloy parts may need post-processing such as machining, grinding, and surface treatment to achieve the design requirements.

Mastar 5A02 aluminum bar purchasing guide

Before buying 5A02 Aluminum Rod from Mastar, please confirm the size and quantity you need. Then, contact our customer service team and we will provide you with the best quality products and the most competitive market prices.

5A02 aluminum bar price

5A02 aluminum bar price: (LME ingot price + processing fee) × weight + packaging fee + transportation fee

Please contact Mastar to inquire about the price and the processing fee per ton of aluminum bars of various specifications. The processing fee of 5A02 aluminum bars of different sizes may vary greatly, and we will provide you with the best quotation.

5A02 aluminum bar quality and appearance

Surface quality: The surface of 5A02 aluminum bars should be smooth and flawless, and there should be no obvious cracks, pores, inclusions or other defects that affect use. High-quality 5A02 aluminum bars are usually surface treated to increase corrosion resistance and aesthetics.

Mechanical properties: The strength and ductility of the alloy should meet the requirements of the specific application. Quality-controlled 5A02 aluminum bars usually meet industrial standards in terms of tensile strength, yield strength and elongation, ensuring their stable performance under stress.

Consistent color: 5A02 aluminum bars generally have a silvery-white metallic luster, uniform color, and no obvious color difference on the surface. 5A02 aluminum bars that have been anodized or polished will have a brighter appearance and are suitable for decorative applications.

Surface treatment: In order to improve corrosion resistance and aesthetics, 5A02 aluminum bars can be anodized, electroplated or sprayed. These surface treatments not only improve durability, but also improve the performance of aluminum bars in specific environments.

Detection methods

Chemical composition analysis: Use a spectrometer (such as a direct reading spectrometer) or chemical analysis method to test the chemical composition of the 5A02 aluminum bar to ensure that it meets the standard requirements of the alloy.

Mechanical property testing: Perform a tensile test to test the mechanical properties of the 5A02 aluminum bar, such as yield strength, tensile strength and elongation. The testing equipment is usually a universal testing machine.

Nondestructive testing: Use ultrasonic flaw detection to detect whether there are cracks, pores and other defects inside the 5A02 aluminum bar to ensure the internal quality of the product.

Dimension detection: Use tools such as calipers and micrometers to measure the diameter, length and surface flatness of the aluminum bar to ensure that it meets the specification requirements.

Surface quality inspection: Observe the surface of the aluminum bar by visual inspection or microscope to check whether there are scratches, oxide scale, inclusions and other defects to ensure that the surface quality meets the standard.

Hardness test: Use a hardness tester to measure the hardness value of the 5A02 aluminum bar to understand whether its hardness performance meets the use requirements.

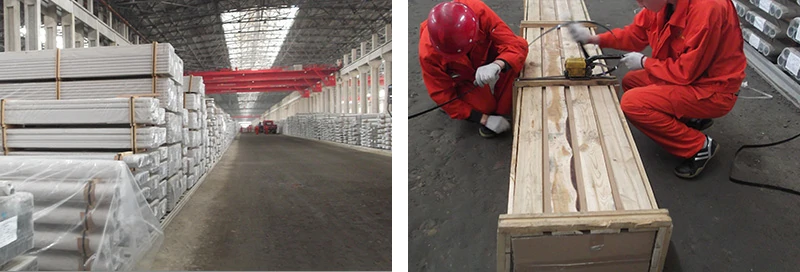

5A02 aluminum bar packaging

- Plastic or kraft paper packaging with moisture-proof desiccant inside.

- Mounted on wooden pallets, reinforced with steel straps, and provided with fumigation certificate.

- Complies with GB/T3199 standard requirements.

- Packaging can be customized according to other customer requirements.

Comparison of 5A02, 5A05, and 5A06 aluminum bars

5A02, 5A05, and 5A06 are all aluminum-magnesium alloys from the 5xxx series, known for their excellent corrosion resistance, good weldability, and moderate to high strength. However, they differ slightly in mechanical performance and typical applications:

- 5A02 aluminum bar features moderate strength with excellent corrosion resistance, making it suitable for marine components, pressure vessels, and general structural use where light weight and durability are required.

- 5A05 aluminum bar offers slightly higher strength and is commonly used in larger welded structures such as railway vehicles, storage tanks, and ship hull components.

- 5A06 aluminum bar delivers the highest strength among the three, along with good toughness and processability. It is ideal for demanding aerospace, military, and structural applications that require both strength and corrosion protection.