The 5A05 aluminum bar is a type of 5000 series aluminum alloy, primarily composed of magnesium as the alloying element. It offers excellent corrosion resistance, moderate strength, and good machinability, making it particularly suitable for marine and industrial applications.

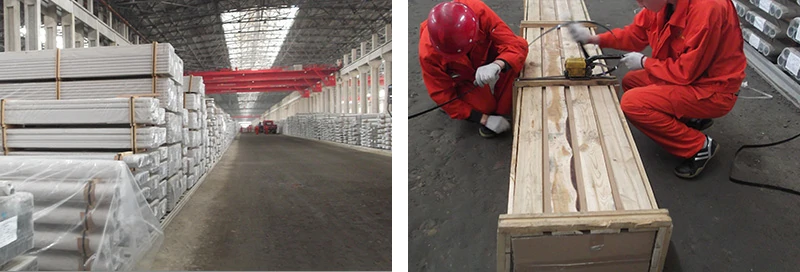

Mastar has a robust inventory system that can provide various sizes of 5A05 aluminum bars, along with cutting and customizable surface treatments to meet a wide range of customer needs.

5A05 aluminum round bar

- Temper: H112

- Popular size: OD:60mm, 100mm, 200mm, 220mm

- Corrosion-resistant and ideal for applications such as automobile parts and marine structures in wet and saltwater environments.

- Find more aluminum round bar products

Below are the hot-selling 5A05 aluminum bar sizes in Mastar's inventory. If there is no size that matches your needs, please contact us and we will provide you with a solution based on our huge inventory advantage.

| Product | Temper | OD(mm) | Length(mm) |

| 5A05 | H112 | 60mm | 6000mm |

| 5A05 | H112 | 70mm | 6000mm |

| 5A05 | H112 | 80mm | 6000mm |

| 5A05 | H112 | 90mm | 6000mm |

| 5A05 | H112 | 100mm | 6000mm |

| 5A05 | H112 | 110mm | 6000mm |

| 5A05 | H112 | 120mm | 4000mm |

| 5A05 | H112 | 130mm | 6000mm |

| 5A05 | H112 | 140mm | 5800mm |

| 5A05 | H112 | 150mm | 5900mm |

| 5A05 | H112 | 160mm | 6000mm |

| 5A05 | H112 | 180mm | 5900mm |

| 5A05 | H112 | 180mm | 6000mm |

| 5A05 | H112 | 190mm | 4000mm |

| 5A05 | H112 | 190mm | 5900mm |

| 5A05 | H112 | 190mm | 6000mm |

| 5A05 | H112 | 200mm | 4000mm |

| 5A05 | H112 | 200mm | 6000mm |

| 5A05 | H112 | 220mm | 6000mm |

Click to see all

Click to see all 5A05 aluminum square bar

- Temper: H112

- Popular size: Section length 5mm-150mm

- Corrosion-resistant with good bending strength, widely used in construction and structural supports.

- Find more aluminum square bar products

5A05 aluminum hexagonal bar

- Temper: H112

- Popular size: Section length 10mm-100mm

- Easy to process and fix with good anti-slip properties, suitable for fasteners, tools, mechanical parts, and building structures.

- Find more aluminum hex bar prodcuts

Chemical composition of 5A05 aluminum bar

| Elements | Composition(%) |

| Si | 0 – 0.5 |

| Cu | 0 – 0.1 |

| Mg | 4.8 – 5.5 |

| Zn | 0 - 0.20 |

| Mn | 0.30 – 0.60 |

| Fe | 0 – 0.5 |

| Al | Remainder |

| Other(each) | ≤ 0.05 |

| Other(total) | ≤ 0.10 |

Mechanical properties of 5A05 aluminum bar

| Temper | OD | Tensile strength | Elongation |

| O, H112 | ≤150mm | 265MPa | 15% |

Note: Square bars and hexagonal bars use the inscribed circle diameter.

Strength and hardness: The strength of 5A05 aluminum is comparable to 5A03, and it is suitable for applications that require medium strength. It has high strength and hardness, and can maintain stable performance in various working environments.

Plasticity: In the annealed state, 5A05 aluminum has high plasticity and is easy to process and form; while in semi-cold hardening, its plasticity is moderate and can still meet certain processing requirements.

Heat treatment: It is worth noting that 5A05 aluminum cannot be strengthened by heat treatment, which means that its strength cannot be further improved by heat treatment.

Processing properties of 5A05 aluminum bar

Processing performance: 5A05 aluminum has good processing performance and can be processed into parts and components of various shapes and sizes through various forming processes.

Welding performance: In the annealed state, 5A05 aluminum has good welding performance and supports a variety of welding methods such as hydrogen atom welding, spot welding, gas welding, and argon arc welding.

Cutting performance: In the annealed state, the cutting performance of 5A05 aluminum is low, but it improves when semi-cold hardening. In addition, when manufacturing parts such as rivets, anodizing treatment is required to increase their surface hardness.

Heat treatment specification of 5A05 aluminum bar

- Homogenization annealing: heating at 460-475℃; keeping warm for 12-14h; air cooling.

- Rapid annealing: heating at 310-350℃; keeping warm for 30-120min; air or water cooling.

- High temperature annealing: heating at 310-335℃; when the finished product thickness is ≥6mm or <6mm, the keeping warm time is 30-180min or 30-120min; air cooling.

- Low temperature annealing: heating at 250-300℃ or 150-180℃; keeping warm for 1-2h or 2-3h air cooling.

Why choose Mastar?

- Customized service: Provide a variety of specifications and surface treatments to meet customers' personalized needs.

- Complete certification: All products are certified by ISO, CE and other international standards to ensure reliable product quality.

- Fast delivery: Sufficient inventory, short delivery time, to meet urgent order needs.

- Quick response: Respond to customer demands and quotations quickly, and give customers the most competitive prices

- Price update: According to the international aluminum price, update the price for customers in real time to let customers know the latest price.

- Free samples: All samples can be provided free of charge, and customers can place orders after passing the test.

Mastar 5A05 aluminum bar purchasing guide

Before purchasing 5A05 aluminum bars from Mastar, please confirm the sizes and quantities you need. Then, contact our customer service team, and we will provide you with the highest quality products at the most competitive market prices..

5A05 aluminum bar price

5A05 aluminum bar price: (LME ingot price + processing fee) × weight + packaging fee + shipping fee.

Please contact Mastar for pricing and the processing fee per ton for various specifications of aluminum bars. The processing fees for different sizes of 5A05 aluminum bars may vary significantly, and we will provide you with the best quotation.

5A05-H112 aluminum bar is the most commonly ordered condition.

5A05 aluminum bar appearance quality

- The surface of 5A05 round bars, square bars, and hex bars must be free from cracks, bubbles, and corrosion spots.

- The thickness of 5A05 round bars, square bars, and hex bars must not exceed the allowable deviation range.

- The surface of 5A05 round bars, square bars, or hex bars must not have deep scratches, wear, dents, or straightening marks that exceed the deviation range.

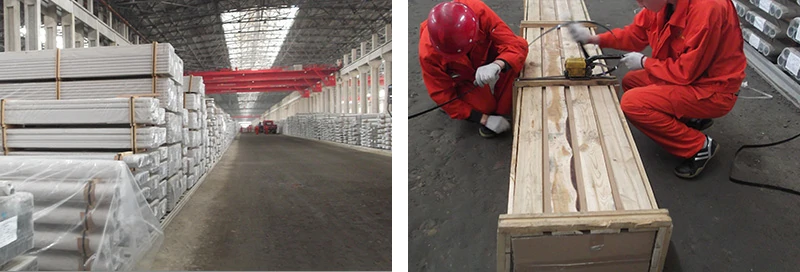

5A05 aluminum bar packaging

- Plastic or kraft paper packaging, including moisture-absorbing desiccants.

- Mounted on wooden pallets, secured with steel straps, and provided with a fumigation certificate.

- Complies with GB/T 3199 standards.

- Packaging can be customized according to other customer requirements.

5A02 aluminum bar packaging

- Plastic or kraft paper packaging with moisture-proof desiccant inside.

- Mounted on wooden pallets, reinforced with steel straps, and provided with fumigation certificate.

- Complies with GB/T3199 standard requirements.

- Packaging can be customized according to other customer requirements.

Comparison of 5A02, 5A05, and 5A06 aluminum bars

5A02, 5A05, and 5A06 are all aluminum-magnesium alloys from the 5xxx series, known for their excellent corrosion resistance, good weldability, and moderate to high strength. However, they differ slightly in mechanical performance and typical applications:

- 5A02 aluminum bar features moderate strength with excellent corrosion resistance, making it suitable for marine components, pressure vessels, and general structural use where light weight and durability are required.

- 5A05 aluminum bar offers slightly higher strength and is commonly used in larger welded structures such as railway vehicles, storage tanks, and ship hull components.

- 5A06 aluminum bar delivers the highest strength among the three, along with good toughness and processability. It is ideal for demanding aerospace, military, and structural applications that require both strength and corrosion protection.

Click to collapse

Click to collapse