6082 aluminum is the strongest material in the 6000 series, often referred to as a "structural alloy." It contains magnesium, manganese, and silicon, which enhance its mechanical strength and corrosion resistance while maintaining good machinability and weldability. The T6 and T651 tempers exhibit excellent strength and machinability, making them ideal for processes like turning, milling, drilling, threading, and welding.

6082 aluminum is commonly made by extrusion and rolling, although it is generally not used for casting as a forged alloy. It cannot be work-hardened, but strength can be increased through heat treatment, though this lowers ductility. It is used in high-stress applications such as trusses, bridges, cranes, and other structural engineering projects.

As a professional aluminum supplier, Msatar offers custom production processes for 6082 aluminum bars according to customer requirements, including extruded bars, cold-worked bars, and forged aluminum bars. Specific size ranges are listed below:

- 6082 extrusion aluminum round bar

- Temper: O,T4, T5, T6,T66

- DIA: 0.4"-16"(10-420mm)

- Spec: BS HE30, EN 2326

- Extruded Rod Size Chart

- 6082 alum cold finished round bar

- Temper: O, T4, T6,T66

- DIA: 0.125"-8"(3-200mm)

- Spec: EN 754

- Cold Finished Rod Size Chart

- 6082 aluminum forged bar

- Temper: 7.8"-40"(200-1000mm)

- Manufactured through forging processes, it possesses exceptionally high strength, fatigue resistance, and heat resistance.

If you need further details on 6082 aluminum bars or custom requirements, feel free to contact our professional team, and we'll help you find the best solution. Quick Quote

Popular 6082 aluminum round bar products

6082 T6 aluminum round bar

The 6082-T6 aluminum bar undergoes solution heat treatment and artificial aging, resulting in high strength and excellent machinability. It is suitable for applications requiring strength and cutting performance. When machining, it is recommended to use chip breakers to improve chip formation. However, due to quenching limitations, some thin-walled profiles may not be available in the T6 condition.

6082 T651 aluminum round bar

The 6082-T651 aluminum bar undergoes solution heat treatment, stress relief, and artificial aging, providing high strength and excellent machining performance. Chip breakers can be used during machining to cut the metal chips into small segments, preventing tangling and improving efficiency. It is ideal for high-strength, precision-machined components, such as those in aerospace and high-stress applications.

6082 T6511 aluminum round barr

The 6082-T6511 aluminum bar undergoes solution heat treatment, stress relief, and artificial aging, offering high strength and excellent machinability. Compared to the T6 condition, the stress-relief process in T6511 improves material stability and machining consistency, reducing the risk of deformation. It is suitable for applications requiring high precision and strength, such as aerospace and structural components.

6082 O aluminum round bar

The 6082 O aluminum bar is in a fully annealed state, offering maximum ductility and excellent forming properties, making it ideal for applications that require complex bending and forming. However, due to its lower strength, the machinability of O-temper 6082 is poor, and it is not suitable for high-stress or high-strength requirements.

6082 T4 aluminum round bar

The 6082-T4 aluminum bar undergoes solution heat treatment and is naturally aged to a stable state, providing good formability, and making it suitable for bending and forming applications. In the T4 condition, it offers medium strength and high ductility and is commonly used for products that do not require cold working.

6082 aluminum round bar hot-selling size chart

| Description | Temper | Diameter mm | Lbs/Ft. | Kg/m |

| 1/8" 6082 aluminum round bar - Extrusion | T6,T651,T6511 | 3 | 0.013 | 0.019 |

| 3/16" 6082 aluminum round bar - Extrusion | T6,T651,T6511 | 4 | 0.023 | 0.034 |

| 1/4" 6082 aluminum round bar - Extrusion | T6,T651,T6511 | 5 | 0.036 | 0.053 |

| 5/16" 6082 aluminum round bar - Extrusion | T6,T651,T6511 | 6 | 0.051 | 0.076 |

| 3/8" 6082 aluminum round bar - Extrusion | T6,T651,T6511 | 8 | 0.091 | 0.136 |

| 1/2" 6082 aluminum round bar - Extrusion | T6,T651,T6511 | 10 | 0.142 | 0.212 |

| 5/8" 6082 aluminum round bar - Extrusion | T6,T651,T6511 | 12 | 0.205 | 0.305 |

| 3/4" 6082 aluminum round bar - Extrusion | T6,T651,T6511 | 16 | 0.365 | 0.543 |

| 7/8" 6082 aluminum round bar - Extrusion | T6,T651,T6511 | 22 | 0.69 | 1.026 |

| 1" 6082 aluminum round bar - Extrusion | T6,T651,T6511 | 25 | 0.891 | 1.325 |

| 1.1/8" 6082 aluminum round bar - Extrusion | T6,T651,T6511 | 28 | 1.117 | 1.663 |

| 1.1/4" 6082 aluminum round bar - Extrusion | T6,T651,T6511 | 32 | 1.459 | 2.171 |

| 1.3/8" 6082 aluminum round bar - Extrusion | T6,T651,T6511 | 35 | 1.746 | 2.598 |

| 1.1/2" 6082 aluminum round bar - Extrusion | T6,T651,T6511 | 38 | 2.058 | 3.062 |

| 1.5/8" 6082 aluminum round bar - Extrusion | T6,T651,T6511 | 41 | 2.395 | 3.565 |

| 1.3/4" 6082 aluminum round bar - Extrusion | T6,T651,T6511 | 45 | 2.886 | 4.294 |

| 1.7/8" 6082 aluminum round bar - Extrusion | T6,T651,T6511 | 48 | 3.283 | 4.886 |

| 2" 6082 aluminum round bar - Extrusion | T6,T651,T6511 | 50 | 3.562 | 5.301 |

| 2.1/8" 6082 aluminum round bar - Extrusion | T6,T651,T6511 | 54 | 4.155 | 6.184 |

| 2.1/4" 6082 aluminum round bar - Extrusion | T6,T651,T6511 | 58 | 4.794 | 7.134 |

| 2.1/2" 6082 aluminum round bar - Extrusion | T6,T651,T6511 | 64 | 5.837 | 8.686 |

| 2.3/4" 6082 aluminum round bar - Extrusion | T6,T651,T6511 | 70 | 6.982 | 10.391 |

| 3" 6082 aluminum round bar - Extrusion | T6,T651,T6511 | 76 | 8.231 | 12.248 |

| 3.1/4" 6082 aluminum round bar - Extrusion | T6,T651,T6511 | 82 | 9.581 | 14.259 |

| 3.1/2" 6082 aluminum round bar - Extrusion | T6,T651,T6511 | 90 | 11.542 | 17.177 |

| 4" 6082 aluminum round bar - Extrusion | T6,T651,T6511 | 100 | 14.25 | 21.206 |

| 4.1/2" 6082 aluminum round bar - Extrusion | T6,T651,T6511 | 115 | 18.845 | 28.045 |

| 5" 6082 aluminum round bar - Extrusion | T6,T651,T6511 | 130 | 24.082 | 35.838 |

| 5.1/2" 6082 aluminum round bar - Extrusion | T6,T651,T6511 | 140 | 27.929 | 41.563 |

| 6" 6082 aluminum round bar - Extrusion | T6,T651,T6511 | 150 | 32.062 | 47.713 |

| 6.1/2" 6082 aluminum round bar - Extrusion | T6,T651,T6511 | 165 | 38.795 | 57.733 |

| 7" 6082 aluminum round bar - Extrusion | T6,T651,T6511 | 180 | 46.169 | 68.707 |

| 7.1/2" 6082 aluminum round bar - Extrusion | T6,T651,T6511 | 190 | 51.441 | 76.553 |

| 8" 6082 aluminum round bar - Extrusion | T6,T651,T6511 | 200 | 56.998 | 84.823 |

| 9" 6082 aluminum round bar - Extrusion | T6,T651,T6511 | 230 | 75.38 | 112.178 |

| 10" 6082 aluminum round bar - Extrusion | T6,T651,T6511 | 250 | 89.06 | 132.536 |

| 12" 6082 aluminum round bar - Extrusion | T6,T651,T6511 | 300 | 128.246 | 190.852 |

| 14" 6082 aluminum round bar - Extrusion | T6,T651,T6511 | 350 | 174.557 | 259.77 |

| 16" 6082 aluminum round bar - Extrusion | T6,T651,T6511 | 400 | 227.993 | 339.292 |

Click to see all

Click to see all Mastar EN AW-6082 aluminum round bar size chart

6082 extruded aluminum round bar

| 1/2" 6063 Aluminum EXT Bar | 1-5/8" 6063 Aluminum EXT Bar | 3-1/2" 6063 Aluminum EXT Bar |

| 9/16" 6063 Aluminum EXT Bar | 1-3/4" 6063 Aluminum EXT Bar | 3-5/8" 6063 Aluminum EXT Bar |

| 5/8" 6063 Aluminum EXT Bar | 1-7/8" 6063 Aluminum EXT Bar | 3-3/4" 6063 Aluminum EXT Bar |

| 11/16" 6063 Aluminum EXT Bar | 2" 6063 Aluminum EXT Bar | 4" 6063 Aluminum EXT Bar |

| 3/4" 6063 Aluminum EXT Bar | 2-1/8" 6063 Aluminum EXT Bar | 4-1/2" 6063 Aluminum EXT Bar |

| 13/16" 6063 Aluminum EXT Bar | 2-1/4" 6063 Aluminum EXT Bar | 5" 6063 Aluminum EXT Bar |

| 7/8" 6063 Aluminum EXT Bar | 2-3/8" 6063 Aluminum EXT Bar | 6" 6063 Aluminum EXT Bar |

| 15/16" 6063 Aluminum EXT Bar | 2-1/2" 6063 Aluminum EXT Bar | 7" 6063 Aluminum EXT Bar |

| 1" 6063 Aluminum EXT Bar | 2-5/8" 6063 Aluminum EXT Bar | 8" 6063 Aluminum EXT Bar |

| 1-1/8" 6063 Aluminum EXT Bar | 2-3/4" 6063 Aluminum EXT Bar | 10" 6063 Aluminum EXT Bar |

| 1-1/4" 6063 Aluminum EXT Bar | 3" 6063 Aluminum EXT Bar | 12" 6063 Aluminum EXT Bar |

| 1-5/16" 6063 Aluminum EXT Bar | 3-1/4" 6063 Aluminum EXT Bar | 14" 6063 Aluminum EXT Bar |

| 1-1/2" 6063 Aluminum EXT Bar | 3-3/8" 6063 Aluminum EXT Bar | 16" 6063 Aluminum EXT Bar |

6082 aluminum cold finish round bar

| 1/2" 6063 Aluminum CF Rod | 1-1/2" 6063 Aluminum CF Rod | 3-1/4" 6063 Aluminum CF Rod |

| 9/16" 6063 Aluminum CF Rod | 1-5/8" 6063 Aluminum CF Rod | 3-3/8" 6063 Aluminum CF Rod |

| 5/8" 6063 Aluminum CF Rod | 1-3/4" 6063 Aluminum CF Rod | 3-1/2" 6063 Aluminum CF Rod |

| 11/16" 6063 Aluminum CF Rod | 1-7/8" 6063 Aluminum CF Rod | 3-5/8" 6063 Aluminum CF Rod |

| 3/4" 6063 Aluminum CF Rod | 2" 6063 Aluminum CF Rod | 3-3/4" 6063 Aluminum CF Rod |

| 13/16" 6063 Aluminum CF Rod | 2-1/8" 6063 Aluminum CF Rod | 4" 6063 Aluminum CF Rod |

| 7/8" 6063 Aluminum CF Rod | 2-1/4" 6063 Aluminum CF Rod | 4-1/2" 6063 Aluminum CF Rod |

| 15/16" 6063 Aluminum CF Rod | 2-3/8" 6063 Aluminum CF Rod | 5" 6063 Aluminum CF Rod |

| 1" 6063 Aluminum CF Rod | 2-1/2" 6063 Aluminum CF Rod | 5-1/2" 6063 Aluminum CF Rod |

| 1-1/8" 6063 Aluminum CF Rod | 2-5/8" 6063 Aluminum CF Rod | 6" 6063 Aluminum CF Rod |

| 1-1/4" 6063 Aluminum CF Rod | 2-3/4" 6063 Aluminum CF Rod | 7" 6063 Aluminum CF Rod |

| 1-5/16" 6063 Aluminum CF Rod | 3" 6063 Aluminum CF Rod | 8" 6063 Aluminum CF Rod |

In addition to standard round bars, Mastar also supplies 6082 aluminum in various other shapes such as square bars, flat bars, and hexagonal bars. If you require different profiles or customized specifications, feel free to contact our team or [explore more 6082 aluminum products] to find the right solution for your project.Quick Quote

As a high-quality aluminum bar supplier, what can we offer you?

- Price Advantage: We support both retail and bulk purchases for metal distributors, offering discounts and rebate policies for B2B customers. Our pricing is transparent, ensuring a competitive advantage with equivalent-quality aluminum bars.

- Fast Delivery: With thousands of tons of stock available, standard sizes can be matched directly from our existing inventory, ensuring rapid shipment. Our advanced equipment and professional team help shorten delivery times and provide convenient logistics, ensuring on-time delivery.

- High-Quality Products: We use high-quality aluminum bar billets and employ precise alloying and heat treatment processes to optimize product strength and ductility. Our uniform cooling and annealing processes ensure high tensile strength and superior performance.

- Excellent Grain Control: Produced via reverse extrusion, we control the cooling rate and homogenization process. Grain ring size is typically controlled to ≤0.5mm, reducing defects and improving material consistency, enhancing product uniformity.

- Comprehensive Quality Testing: We strictly implement multiple inspection processes, including tensile strength, elongation performance, ultrasonic testing, metallographic inspection, etc., ensuring that the aluminum bars meet AMS, EN, NADCAP, and other certification standards.

- Customer Service: We provide comprehensive after-sales service to address any customer concerns. Our experienced technical team offers professional consulting and guidance, establishing a robust customer service system to ensure a premium service experience.

Chemical composition of 6082 aluminum round bar

| Element | EN AW-6082 |

| Si | 0.7-1.3 |

| Fe | 0.5 |

| Cu | 0.1 |

| Mn | 0.4-1.0 |

| Mg | 0.6-1.2 |

| Cr | 0.25 |

| Zn | 0.2 |

| Ti | 0.1 |

| Others (Each) | 0.05 |

| Others (Total) | 0.15 |

| Al | Rem |

Physical properties of 6082 aluminum round bar

| Physical Property | Value |

| Density | 2.70 g/cm³ |

| Melting Point | 555℃ |

| Thermal Expansion | 24x10^-6 /K |

| Modulus of Elasticity | 70GPa |

| Thermal Conductivity | 180 W/m.K |

| Electrical Resistivity | 0.038 x10^-6Ω.m |

Mechanical properties of 6082 aluminum round bar

6082 extruded aluminum round bar

| Mechanical Properties | O/H111 | T4 | T6(OD<20mm) | T6(20>OD≤150mm) | T6(150>OD≤200mm) | T6(150>OD≤200mm) |

| Tensile strength Rm/Mpa | 160 | 205 | 295 | 310 | 280 | 270 |

| Yield strength Rp0.2/Mpa | 110 | 110 | 250 | 260 | 240 | 200 |

| Elongation | 12-14% | 12-14% | 6-8% | 8% | 6% | 6% |

| Hardness | 35 | 70 | 95 | 95 | 95 | 95 |

6082 aluminum cold finish round bar

| Mechanical Properties | O/H111 | T4 | T6 |

| Tensile strength Rm/Mpa | 160 | 205 | 310 |

| Yield strength Rp0.2/Mpa | 110 | 110 | 255 |

| Elongation | 13-15% | 12-14% | 9-10% |

| Hardness | 35 | 70 | 95 |

Best application areas for 6082 aluminum round bar

6082 Aluminum Round Bar for Bridges

6082 Aluminum Round Bar for Bridges- The 6082 aluminum round bar is widely used in bridge engineering, especially for main beams, support structures, bridge decks, and connectors, due to its high strength, excellent corrosion resistance, and outstanding structural stability.

6082 Aluminum Round Bar for Cranes

6082 Aluminum Round Bar for Cranes- With its high strength, superior mechanical performance, and excellent fatigue resistance, the 6082 aluminum round bar ensures stability in high-load crane operations. It is commonly used to manufacture key crane components such as booms, support structures, and connectors.

6082 Aluminum Round Bar for High-Stress Components

6082 Aluminum Round Bar for High-Stress Components- The 6082 aluminum round bar is extensively used in high-stress components like bridge supports, crane arms, and heavy-duty frames due to its high strength and excellent corrosion resistance. Its outstanding mechanical properties ensure structural stability under heavy loads and extreme conditions.

6082 Aluminum Round Bar for Ore Buckets

6082 Aluminum Round Bar for Ore Buckets- Due to its medium strength and excellent corrosion resistance, the 6082 aluminum round bar is ideal for manufacturing ore buckets. Its good machinability and structural stability allow it to withstand the heavy loads and high-wear environments of ore handling, ensuring long-term reliable operation.

6082 aluminum bar purchasing guide

1. Comprehensive Documentation

Mastar provides detailed quality test reports, including raw material certificates, lab test reports, fumigation reports, specification guides, commercial invoices, and warranties, ensuring transparency and traceability for every batch of products.

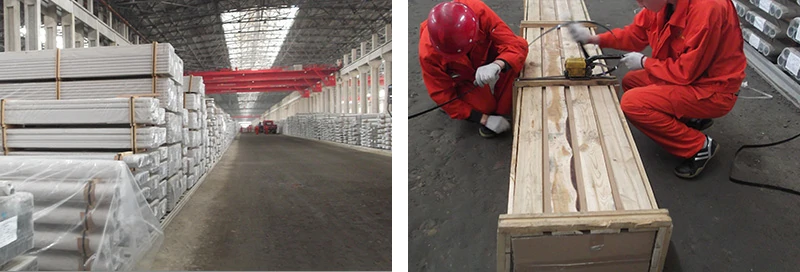

2. Fine Export Packaging

In international freight, the quality of the packaging materials is critical in preventing rust, corrosion, scratches, deformation, and other damages during transportation. Mastar has years of experience in export packaging, offering safe and reliable packaging solutions for thousands of enterprises. Using fumigated wooden boxes, pallets, and other high-quality materials, our packaging damage rate is only one-third of the industry average.

3. Professional Container Loading Solutions

Our experienced follow-up team provides flexible loading options, including 20/40-foot containers or bulk carriers. No matter the size or shape of your goods, we can customize a loading solution, typically saving 15% of container space, and reducing logistics costs.

6082 aluminum knowledge center

6082 aluminum alloy equivalent grades

| UNS | EN | DIN | ISO | BS (OLD) | USA | WNR |

| A96082 | EN AW-6082 | AlMgSi1 | Al Si1MgMn | HE30 | AA6082 | 3.2315 |

6082 aluminum round bar standards

- BS HE30 6082 Extrusions

- BS L111 Alloy 6082-T6 Bars and Sections

- EN 755 - Aluminum and Aluminum Alloys - Extruded Rod/Bar, Tube and Profiles

- EN 754 - Aluminum and Aluminum Alloys - Cold Drawn Rod/Bar, Tube and Profiles

- ASTM B221 - Aluminum and Aluminum-Alloy Extruded Bars, Rods, Wire, Profiles, and Tubes

- BS EN 2326 -Aerospace series -Aluminium alloy AL-P6082-T6. Extruded bars and sections a or D ≤ 200 mm

- BS EN 2636 - Aerospace series -Aluminium alloy AL-P6082-T6. Extruded bars and sections a or D ≤ 200 mm (with peripheral coarse grain control)

- DIN EN 4273 - Aerospace series - Aluminium alloy AL-P6082-T6511 - Extruded bars and sections a or D 200 mm

- DIN EN 4274 - Aerospace series - Aluminium alloy AL-P6082-T6511 - Extruded bars and sections a or D 200 mm (with peripheral coarse grain control)

How to Control the Grain Ring in 6082 Aluminum Round Bar?

According to BS EN 2636 and DIN EN 4274 aerospace standards, strict control over the grain ring is required for 6082 aluminum alloy round bars with a diameter not exceeding 200 mm to ensure excellent performance and reliability in high-stress environments. Mastar's methods for controlling the grain ring include:

1. Reverse Extrusion Process

Through advanced reverse extrusion, Mastar achieves a more uniform material structure, strictly controlling the grain ring to ≤0.5 mm. This improves the toughness and consistency of the bars, effectively reducing fractures and defects.

2. Precise Homogenization Treatment

Mastar employs precise homogenization processes to refine the grain structure and reduce component segregation, controlling grain ring formation at the source and ensuring premium product performance.

3. Strict Temperature and Cooling Control

We rigorously control the processing temperature and cooling rate to prevent excessive grain growth during processing. Through such fine control, our 6082 aluminum round bars maintain a refined grain structure.

Welding Performance of 6082 Aluminum Alloy

6082 aluminum has excellent weldability, though the overall strength in the heat-affected zone may slightly decrease. For welding within the same alloy, 4043 aluminum welding wire is recommended. When welding 6082 to 7005 aluminum, 5356 aluminum welding wire should be used.

Extrusion Performance of 6082 Aluminum Round Bar

Using 6063 aluminum alloy as a reference, with an extrusion index of 100, 6082 aluminum's extrusion index is typically 55 due to its magnesium and manganese content. This makes it more challenging to produce thin-walled and complex shapes. Additionally, the extrusion surface finish of 6082 is not as smooth as other alloys in the 6000 series. Therefore, 6082 aluminum is more suitable for thick-walled load-bearing structural components, providing superior structural stability in high-stress applications.

Click to collapse

Click to collapse