4032 aluminum bar is an AL-Si alloy and is the highest strength alloy in the 4000 series. It can be heat-treated, has high heat resistance, and excellent wear resistance, making it commonly used for automotive pistons, bearings, and bushings. Due to its high silicon content, it has very low ductility, making this alloy difficult to extrude.

Stock of 4032 aluminum round bar

Mastar has 4032 aluminum round bars of different sizes in stock. We can provide customized cutting services. The same diameter can be cut. If it does not match your ideal size, please contact us in time..

| Product | Diameter(mm) | Diameter(inch) |

| 4032-T1 aluminum round bar | 20mm | 0.79" |

| 4032-T1 aluminum round bar | 30mm | 1.18" |

| 4032-T1 aluminum round bar | 40mm | 1.57" |

| 4032-T1 aluminum round bar | 50mm | 1.97" |

| 4032-T1 aluminum round bar | 80mm | 3.15" |

| 4032-T1 aluminum round bar | 90mm | 3.54" |

| 4032-T1 aluminum round bar | 100mm | 3.94" |

| 4032-T1 aluminum round bar | 110mm | 4.33" |

| 4032-T1 aluminum round bar | 120mm | 4.72" |

| 4032-T1 aluminum round bar | 130mm | 5.12" |

| 4032-T6 aluminum round bar | 20mm | 0.79" |

| 4032-T6 aluminum round bar | 30mm | 1.18" |

| 4032-T6 aluminum round bar | 40mm | 1.57" |

| 4032-T6 aluminum round bar | 50mm | 1.97" |

| 4032-T6 aluminum round bar | 80mm | 3.15" |

| 4032-T6 aluminum round bar | 90mm | 3.54" |

| 4032-T6 aluminum round bar | 100mm | 3.94" |

| 4032-T6 aluminum round bar | 110mm | 4.33" |

| 4032-T6 aluminum round bar | 120mm | 4.72" |

| 4032-T6 aluminum round bar | 130mm | 5.12" |

| 4032-T6 aluminum round bar | 150mm | 5.13" |

| 4032-T6 aluminum round bar | 160mm | 6.3" |

| 4032-T6 aluminum round bar | 178mm | 7.01" |

| 4032-T6 aluminum round bar | 201mm | 7.91" |

| 4032-T6 aluminum round bar | 215mm | 8.46" |

| 4032-T6 aluminum round bar | 227mm | 8.94" |

| 4032-T6 aluminum round bar | 252mm | 9.92" |

| 4032-T6 aluminum round bar | 278mm | 10.94" |

| 4032-T6 aluminum round bar | 314mm | 12.36" |

| 4032-T6 aluminum round bar | 350mm | 13.78" |

| 4032-T6 aluminum round bar | 372mm | 14.65" |

| 4032-T6 aluminum round bar | 425mm | 16.73" |

| 4032-T6 aluminum round bar | 435mm | 17.13" |

| 4032-T6 aluminum round bar | 518mm | 20.39" |

| 4032-T6 aluminum round bar | 607mm | 23.9" |

| 4032-T6 aluminum round bar | 682mm | 26.85" |

| 4032-T6 aluminum round bar | 750mm | 29.53" |

| 4032-T6 aluminum round bar | 930mm | 36.61" |

| 4032-T6 aluminum round bar | 1150mm | 45.28" |

Click to see all

Click to see all Popular sizes of 4032 aluminum round bars

Here is the size table of 4032 aluminum round bars favored by Mastar's customers. If any of these sizes match your needs, please contact us as soon as possible.

| Product | Diameter(inch) | Length(feet) |

| 0.5" Dia 4032-T6 aluminum round bar | 0.5" | 12' |

| 0.625" Dia 4032-T6 aluminum round bar | 0.625" | 12' |

| 0.688" Dia 4032-T6 aluminum round bar | 0.688" | 12' |

| 0.75" Dia 4032-T6 aluminum round bar | 0.75" | 12' |

| 0.875" Dia 4032-T6 aluminum round bar | 0.875" | 12' |

| 1" Dia 4032-T6 aluminum round bar | 1" | 12' |

| 1.125" Dia 4032-T6 aluminum round bar | 1.125" | 12' |

| 1.25" Dia 4032-T6 aluminum round bar | 1.25" | 12' |

| 2" Dia 4032-T6 aluminum round bar | 2" | 12' |

| 2.5" Dia 4032-T6 aluminum round bar | 2.5" | 9' |

| 3.375" Dia 4032-T6 aluminum round bar | 3.375" | 40' |

| 4.5" Dia 4032-T6 aluminum round bar | 4.5" | 12' |

| 6" Dia 4032-T6 aluminum round bar | 6" | 24' |

| 0.5" Dia 4032-T651 aluminum round bar | 0.5" | 12' |

| 0.625" Dia 4032-T651 aluminum round bar | 0.625" | 12' |

| 0.688" Dia 4032-T651 aluminum round bar | 0.688" | 12' |

| 0.75" Dia 4032-T651 aluminum round bar | 0.75" | 12' |

| 0.875" Dia 4032-T651 aluminum round bar | 0.875" | 12' |

| 1" Dia 4032-T651 aluminum round bar | 1" | 12' |

| 1.125" Dia 4032-T651 aluminum round bar | 1.125" | 12' |

| 1.25" Dia 4032-T651 aluminum round bar | 1.25" | 12' |

| 2" Dia 4032-T651 aluminum round bar | 2" | 12' |

| 2.5" Dia 4032-T651 aluminum round bar | 2.5" | 9' |

| 3.375" Dia 4032-T651 aluminum round bar | 3.375" | 40' |

| 4.5" Dia 4032-T651 aluminum round bar | 4.5" | 12' |

| 6" Dia 4032-T651 aluminum round bar | 6" | 24' |

Click to see all

Click to see all Why choose Mastar's 4032 aluminum round bars?

- Mastar's aluminum round bars undergo optimized processing, resulting in a smooth surface and high dimensional accuracy, making them suitable for various machining methods such as turning, milling, and drilling, particularly in precision machining applications.

- The high surface quality and consistent dimensional tolerances of Mastar's aluminum round bars contribute to improved machining efficiency and reduced processing waste.

- Mastar's 4032 aluminum round bars exhibit excellent wear resistance and high-temperature performance, capable of stable operation in environments ranging from 200°C to 300°C.

- The microstructure of 4032 aluminum alloy bars shows no primary silicon, with eutectic silicon distributed as spots, measuring between 1.59-8.9 μm.

- The composition of 4032 aluminum bars contains 12.2% silicon, which provides good welding characteristics.

- Mastar's 4032 aluminum bars can be heat-treated to achieve yield strength levels comparable to 6061-T6.

- 4032 aluminum bars can be regarded as heat-treatable 4047 types or laser-weldable 6061 types.

- Mastar's 4032 aluminum round bars eliminate the need for hard coat anodizing in high-temperature forging applications..

Popular applications of Mastar's 4032 aluminum round bars

- Laser-welded caps

- Recording equipment

- Copier parts

- Brake master cylinders

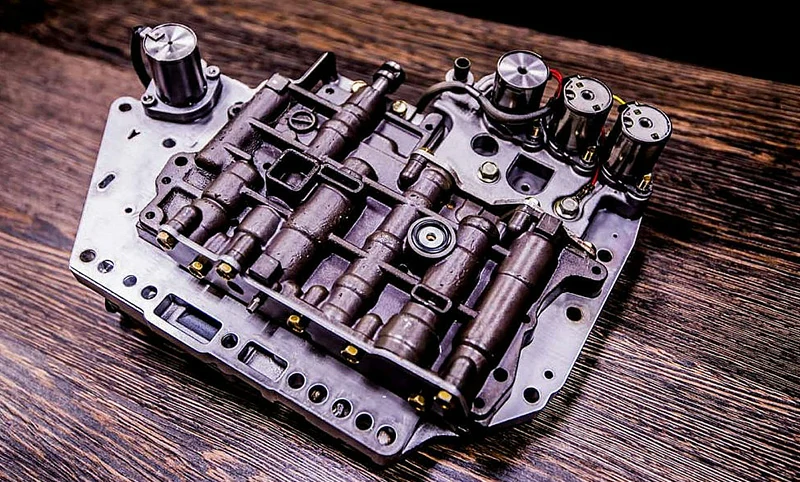

- Transmission valves

- Bushings for rack and pinion steering systems

- Bearings

- Hydraulic applications

- Forged pistons

Performance of 4032 aluminum round bars

| Temper | Hardness, Brinell | Tensile Strength, Ultimate | Tensile Strength, Yield | Elongation | CTE, linear |

| T6 | 120HB | 379MPa | 317MPa | 9% | 21.0 µm/m-℃ |

| T651 | 120HB | 359MPa | 331MPa | 4% | 19.4µm/m-℃ |

Related products of 4032 aluminum bars

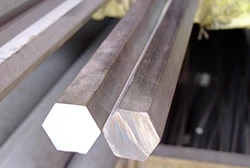

In addition to round bars, Mastar provides 4032 aluminum bars in various shapes such as square, flat, hex and othe procesion ground bars to meet different application requirements. Below is a showcase of other 4032 aluminum bar products — feel free to contact us for custom specifications.Quick Quote

- 4032 aluminum casting bars

- 4032 aluminum square bars

- 4032 aluminum hex bars

Production process of 4032 aluminum round bars

Casting: First, aluminum ingots are mixed and melted with alloying elements like silicon and magnesium in specific proportions to form the 4032 alloy. The molten alloy is then cast into aluminum billets using processes such as semi-continuous casting.

Extrusion: The cast aluminum billets are preheated, typically around 400°C, and then extruded into round bars using an extrusion press. During this process, the billet is forced into a die to form the round shape.

Heat treatment: The extruded aluminum round bars undergo heat treatment to enhance their strength and hardness. 4032 aluminum is usually subjected to solution treatment and aging (such as T6 treatment) to achieve optimal mechanical properties and deformation resistance.

Stretching and straightening: To ensure good dimensional accuracy and surface quality, the heat-treated round bars are stretched and straightened. This step eliminates internal stresses and ensures the straightness of the bars.

Surface treatment: Depending on requirements, 4032 aluminum round bars can undergo surface treatments like anodizing, polishing, or sandblasting to improve corrosion resistance and appearance.

Quality inspection and packaging: After production, the aluminum round bars are subject to quality inspection, including checks on dimensional accuracy, surface quality, and mechanical properties. Qualified products are then packaged and prepared for shipping or delivery.

Display of finished 4032 aluminum pistons

Advantages of 4032 aluminum pistons

4032 forged pistons are made from a high-silicon material, which minimizes thermal expansion, allowing for a tighter fit between the piston and bore. This closer clearance results in smoother overall engine operation.

4032 is a very stable alloy that resists distortions such as ring integrity. The strength and stability of this alloy also contribute to a longer lifespan.

Disadvantages of 4032 aluminum pistons

4032 aluminum alloy has poor ductility; therefore, if you plan to build a supercharged HEMI stroker engine, we do not recommend using this type of piston.

4032 aluminum pistons vs. 2618 aluminum pistons

2618 and 4032 are two of the most commonly used piston materials, and there are many differences between them.

- High silicon content (12%), low copper content

- Lower expansion, allowing tighter cold clearances

- Better wear resistance, longer engine life

- Better sealing, less leakage

- Slightly lighter, helps improve engine performance

- Street performance and some racing applications, where wear resistance, low noise and low expansion are important

- Low silicon content, high copper content

- Better ductility, improved crack resistance

- Better high temperature strength, suitable for high load, high stress applications

- Slightly heavier

- Greater linear expansion rate, requiring larger piston clearance

- Racing applications, requiring high strength and high temperature resistance, such as superchargers, turbochargers or NOx

Click to collapse

Click to collapse