6026 aluminum alloy bars are eco-friendly aluminum alloys from Wuxi, featuring good machinability, outstanding hard anodizing capabilities, excellent weldability, and corrosion resistance. They are widely used in the manufacturing of automotive and electronic components.

6026 aluminum bars also exhibit superior cutting performance, making them particularly suitable for high-speed automatic lathe processing.

Specifications of 6026 aluminum bar

- EN 755

- EN 573

- EN 754

- ASTM B221

Product classification of 6026 aluminum bars

6026 extruded aluminum bars

- Manufactured using a high-temperature extrusion process, featuring good mechanical properties and corrosion resistance.

- Characteristics: Smooth surface, easy to machine.

- Applications: Suitable for structural components and load-bearing applications.

Mechanical properties table for 6026 extruded aluminum bars:

| Temper | Dimension (mm) | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Hardness (HB) |

| T6 | D ≤ 140 | Min. 370 | Min. 300 | 8 | 95 |

| T6 | 140 < D ≤ 200 | Min. 340 | Min. 250 | 8 | 90 |

| T6 | 200 < D ≤ 250 | Min. 300 | Min. 200 | 8 | 90 |

6026 cold drawn aluminum bars

- Processed through cold drawing, offering high dimensional accuracy and a smooth surface.

- Characteristics: Cold drawn aluminum bars typically exhibit better strength and hardness.

- Applications: Suitable for precision components and applications requiring high strength.

Mechanical properties table for 6026 cold drawn aluminum bars:

| Temper | Dimension (mm) | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Hardness (HB) |

| T6 | D ≤ 80 | Min. 370 | Min. 300 | 8 | 95 |

| T8 | D ≤ 80 | Min. 345 | Min. 315 | 4 | 95 |

| T9 | D ≤ 80 | Min. 360 | Min. 330 | 4 | 95 |

Stock size range of 6026 aluminum bars

6026 Aluminum Round Bars

6026 Aluminum Round Bars- Temper: T6, T8, T9

- Diameter: 6.0 mm - 200.0 mm

- Length: 1-6 m (can be cut)

6026 Aluminum Square Bars

6026 Aluminum Square Bars- Temper: T6, T8, T9

- Side Length: 6.0 mm - 200.0 mm

- Length: 1-6 m (can be cut)

6026 Aluminum Rectangular Bars

6026 Aluminum Rectangular Bars- Temper: T6, T8, T9

- Width x Height: 10 mm x 5 mm - 200 mm x 100 mm

- Length: 1-6 m (can be cut)

6026 Aluminum Hexagonal Bars

6026 Aluminum Hexagonal Bars- Temper: T6, T8, T9

- Side Length: 10 mm - 50 mm

- Length: 1-6 m (can be cut)

In addition to 6026 aluminum bars, Mastar also supplies a wide range of aluminum bar alloys in various shapes such as round bars, square bars, flat bars, and hex bars. If you are looking for alternatives with similar machinability or mechanical strength, feel free to explore our whole aluminum bar product pages or contact us for assistance.Quick Quote

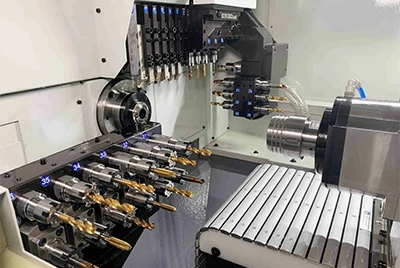

Machining characteristics of 6026 aluminum bars

Excellent Cutting Performance: 6026 aluminum alloy produces tightly curled chips during machining, reducing interference in the cutting process and enhancing work efficiency.

Rapid Metal Removal Rate: This material allows for efficient metal removal, significantly shortening processing time and lowering production costs.

Consistent Machining Quality: Optimized machinability ensures that each batch of products meets consistent quality standards.

High Adaptability: 6026 aluminum alloy is suitable for various machining processes, including turning, milling, and drilling, to meet diverse production needs.

With its outstanding machinability and production efficiency, 6026 aluminum bar is an ideal choice for precision-turned parts — alongside other free-machining aluminum alloys designed for CNC and high-speed machining.

Chemical composition of 6026 aluminum bars

One notable advantage of 6026 aluminum alloy is that it is free from tin (Sn), which means that machined components can maintain higher strength and toughness under high temperature and pressure conditions, reducing the risk of brittleness and cracking.

| Chemical Element | % Present |

| Manganese (Mn) | 0.20 - 1.00 |

| Iron (Fe) | 0.0 - 0.70 |

| Magnesium (Mg) | 0.60 - 1.20 |

| Silicon (Si) | 0.60 - 1.40 |

| Copper (Cu) | 0.20 - 0.50 |

| Lead (Pb) | 0.0 - 0.40 |

| Bismuth (Bi) | 0.50 - 1.50 |

| Zinc (Zn) | 0.0 - 0.30 |

| Tin (Sn) | 0.0 - 0.05 |

| Chromium (Cr) | 0.0 - 0.30 |

| Titanium (Ti) | 0.0 - 0.20 |

| Other (Each) | 0.05 max |

| Others (Total) | 0.15 max |

| Aluminium (Al) | Balance |

Physical properties of 6026 aluminum bar

| Physical Property | Value |

| Density | 2.72 g/cm³ |

| Thermal Expansion | 23.4 x10^-6 /K |

| Modulus of Elasticity | 69 GPa |

| Thermal Conductivity | 172 W/m.K |

| Electrical Resistivity | 0.039 x10^-6 Ω .m |

Equivalent specifications of 6026 aluminum bars

- A95754

- Al 3.1Mg Mn Cr

- Al Mg3

- AW-5754

Advantages of 6026 Aluminum Bars

- Excellent Corrosion Resistance: Ensures product reliability in harsh environments.

- Suitable for Anodizing: Can provide decorative and hard anodized finishes, enhancing appearance and durability.

- High Strength: The strength of 6026 aluminum bars is comparable to that of alloys 2011 and 2030.

- Good Weldability: Suitable for various welding applications.

- Ease of Cutting and Machinability: Particularly well-suited for high-speed automatic lathes and machining centers, improving production efficiency.

- Eco-Friendly Characteristics: Complies with EU environmental directives.

Applications of 6026 aluminum bars

6026 aluminum alloy can replace 6082 or 6081 alloys, particularly suitable for mass-produced finished components.

- Machined Parts: Especially well-suited for components processed on high-speed automatic lathes.

- Automotive Parts: Widely used in critical components such as braking systems.

- Electrical and Electronic Components: Meets the demands for high precision and corrosion resistance.

- Aerospace Applications: In high-strength and lightweight requirements within the aerospace sector.

- Building and Structural Applications: Can be used to manufacture building frames and support structures.

Quality inspection report — traceable

Our products undergo strict quality control, providing a complete set of quality inspection reports.

- Ultrasonic Testing: Ensures no internal defects.

- Chemical Composition Analysis: Complies with industry standards.

- Mechanical Performance Testing: Verifies product strength.

- Non-Destructive Testing: Comprehensive hazard assessment.

- Appearance Inspection: Striving for perfection.

Similar Products to 6026 Aluminum Bars

6026 aluminum alloy is an excellent alternative to 6061 and 6082 alloys, particularly suitable for mass machining on high-speed automatic lathes and machining centers.

The minimum tensile strength of 6026 bars is comparable to that of 2011 and 2030 alloys, ensuring strength and reliability.