2014 is the second most popular of the 2000 series aluminum alloys, after 2024. It is commonly extruded and forged and is a strong alloy that is well suited for the aerospace industry.

MASTAR 2014 aluminum bar product introduction

Stock product types: 2014 cold worked bars; 2014 extruded bars; 2014 forged bars;

Equivalent product names: UNS A92014, ISO AICu4SiMg, Aluminium 2014, AA2014, AI2014

Round bar diameter range: 5-100mm (cold drawn bar); φ5-600mm (extruded bar); φ100-650mm (forged bar)

Length: Can be cut to any length.

Surface treatment: mill finish, anodized, bright, black, polished …

MASTAR 2014 aluminum cold drawn bar

- Temper: O, F, T4, T6, T351, T651

- Production executable standards:

- QQ-A-225/4 2014-T4 T6 Cold finished bar

- BS 2 L87 2014A-T6 Bar

- BS L102 2014A-T4 Bar

- BS L168 2014A-T6 Bar

| 2014 Aluminum Cold Drawn Bar Product Mechanical Properties Reference Table | |||||

| Temper | Diameter or thickness mm | Ultimate Tensile Strength R m /MPa | Yield Tensile Strength Rp0.2/MPa | Elongation at Break % | |

| A | A 50mm | ||||

| O | ≤100 | ≤240 | - | ≥10 | ≥12 |

| T4, T351 | ≤100 | ≥380 | ≥220 | ≥12 | ≥16 |

| T6, T651 | ≤100 | ≥450 | ≥380 | ≥ | ≥8 |

| F | ≤100 | - | - | - | - |

Drawn rods are manufactured by a cold drawing process. This process usually involves stretching the material through a die, reducing its diameter and increasing dimensional accuracy.

- High precision: drawn bars have tighter dimensional tolerances and surface finish for applications requiring higher precision.

- High strength and hardness: 2014 aluminum alloy itself has high strength. Through cold drawing, the strength and hardness of the drawn rod are further improved, making it suitable for applications that require extremely high strength and wear resistance.

- Excellent fatigue properties: the fatigue resistance of 2014 aluminum alloy is maintained or enhanced after drawing, making it perform well in high stress cycle environments.

- Lower ductility: the cold working process may reduce the ductility of 2014 aluminum alloy, but it still maintains its good mechanical properties.

MASTAR 2014 aluminum extruded bars

- Temper: T4, T6, T6511, T4511, T42

- Production executable standards:

- BS L168 2014A-T6 / T6511 Bar

- QQ-A-200/2 2014-T4 2014-T6

- EN 2100 2014A-T4511 Extruded bar

- EN 2324 2014A-T6

- EN 2384 2014A-T6511 Extruded bar

| 2014 Aluminum Alloy Extruded Rod Mechanical Properties Reference Table | |||||

| Temper | Diameter (square rod, Hexagonal rod finger incision Circle diameter) /mm | Ultimate Tensile Strength R m /MPa | Yield Tensile Strength Rp0.2/MPa | Elongation at Break % | |

| A(%) | A 50mm (%) | ||||

| T4 T4511 | ≤25 | 370 | 230 | 13 | 11 |

| >25-75 | 410 | 270 | 12 | - | |

| >75-150 | 390 | 250 | 10 | - | |

| >150-200 | 350 | 230 | 8 | - | |

| T6 T6511 | ≤25 | 415 | 370 | 6 | 5 |

| >25-75 | 465 | 415 | 7 | - | |

| >75-150 | 430 | 520 | 7 | - | |

| >150-200 | 420 | 350 | 6 | - | |

| >200-250 | 355 | 320 | 5 | - | |

Extruded rods are made through a high temperature extrusion process, maintaining the natural characteristics of 2014 aluminum alloy and are ideal for the production of large and complex cross-section structural parts.

- Uniform strength: 2014 aluminum alloy extruded rods maintain uniform high strength after processing, suitable for structural applications.

- Good processability and ductility: the extrusion process retains the good ductility and processability of 2014 aluminum alloy, making it suitable for applications that require further processing, forming or welding.

- Excellent heat treatment performance: the mechanical properties of extruded rods can be further improved after heat treatment, and they are widely used in occasions that require precision manufacturing and subsequent heat treatment.

MASTAR 2014 aluminum forged rod

- Temper: T4, T6

- Production executable standards:

- BS 2 L77: 2014A Forging stock

- BS L103: 2014A-T4 Forging Stock

- AMS 4133: 2014-T6 Forging

- AMS 4134: 2014-T6 Die Forging

- Excellent strength and hardness: through the forging process, the 2014 aluminum alloy is plastically deformed at high temperature, which further improves the internal structural compactness of the material, thus giving the forged rod higher strength and hardness, which is particularly suitable for high stress and high load applications.

- High precision shape: the forging process allows 2014 aluminum alloy to be formed into a variety of complex shapes while maintaining excellent dimensional accuracy and surface finish. This makes forged bars excellent in making precision parts.

- Enhanced structural integrity: the forging process compresses the material, tightening the grain structure, reducing defects, and improving fatigue and impact resistance, ensuring long-term durability in high-stress environments.

MASTAR 2014 aluminum bar supply product shape

- 2014 Aluminum Round Bar

Diameter 5-600mm

- 2014 Aluminum Flat Bar

Thickness: 2-200mm

- 2014 Aluminum Square Bar

Distance between edges: 5-200mm

- 2014 Aluminum Rectangular Bar

Thickness: 2-200mm

- 2014 Aluminum Hexagonal Rod

Distance between edges: 5-200mm

- Other custom shaped aluminum bars

Customizable size

In addition to 2014 aluminum bars, Mastar also supplies a wide range of aluminum bar alloys in various shapes such as round bars, square bars, flat bars, and hex bars. If you are looking for alternatives with similar machinability or mechanical strength, feel free to explore our whole aluminum bar product pages or contact us for assistance.Quick Quote

2014 aluminum rod chemical composition reference table

| Element | Chemical component % |

| Aluminum (Al) | 90.4 to 95 |

| Copper (Cu) | 3.9 to 5.0 |

| Silicon (Si) | 0.5 to 1.2 |

| Manganese (Mn) | 0.4 to 1.2 |

| Magnesium (Mg) | 0.2 to 0.8 |

| Iron (Fe) | 0 to 0.7 |

| Zinc (Zn) | 0 to 0.25 |

| Zirconium (Zr) | 0 to 0.2 |

| Titanium (Ti) | 0 to 0.15 |

| Chromium (Cr) | 0 to 0.1 |

| Residuals | 0 to 0.15 |

MASTAR 2014 aluminum rod performance advantages

Excellent machinability: 2014 aluminum alloy performs well in the machining process, especially in the annealed state, and is easy to cut. This makes it widely used in the aerospace industry and can meet the machining needs of precision parts.

Resistance to pitting and stress cracking corrosion: 2014 aluminum alloy has good resistance to pitting and stress cracking corrosion, especially in chloride and sulfide environments, which enables it to maintain crack-free characteristics even in harsh chemical environments.

Heat-treatable strengthening: through heat treatment process, 2014 aluminum alloy can further improve its mechanical properties, making it perform better in various applications.

High temperature resistance: 2014 aluminum alloy can still maintain strength and durability in high temperature environment without obvious deformation. This makes it very reliable in high temperature applications, such as multi-stage rocket first stage fuel tanks and spacecraft components.

Good weldability: although 2014 aluminum alloy has poor arc welding and gas welding performance, it performs well in contact welding, spot welding and seam welding, suitable for applications with crack-free materials and can maintain structural integrity.

MASTAR 2014 aluminum bar cooperation areas

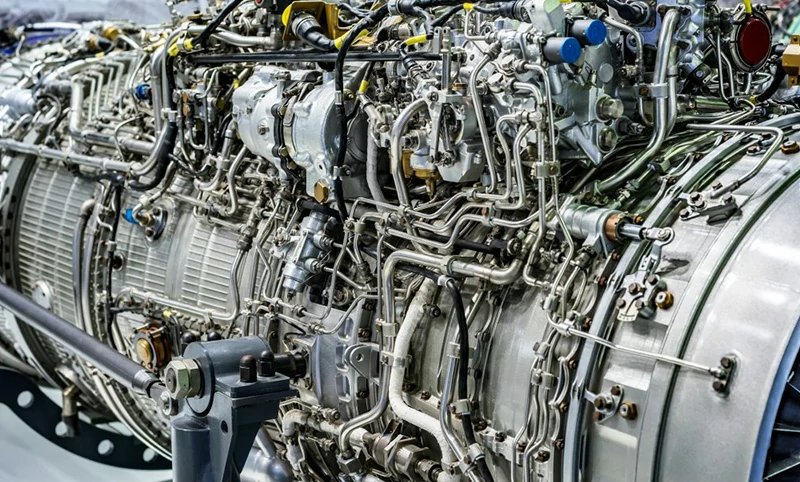

Aerospace structural components: used in aircraft frames and engine components, capable of withstanding high temperatures and loads.

Military equipment: used in missiles, military vehicles and other parts to ensure the stability and reliability of equipment under extreme conditions.

High-performance automobiles: used to manufacture suspension systems and car bodies, with lightweight and high-strength characteristics.

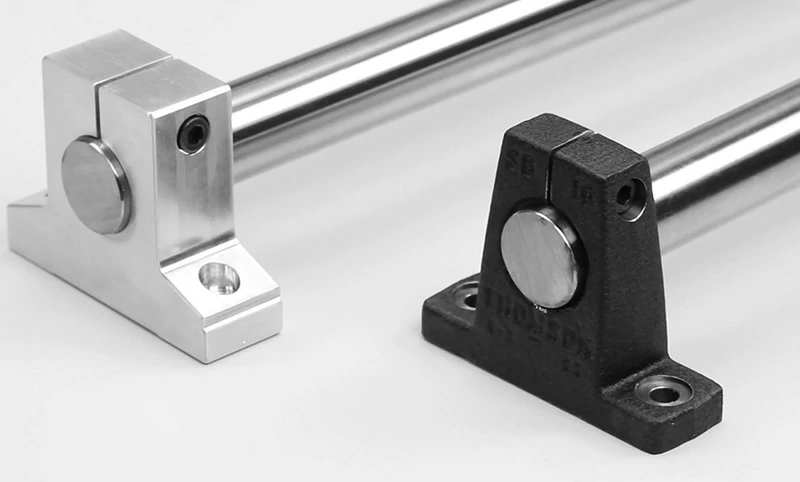

Industrial machinery: used for shafts, gears and other parts, providing high strength and wear resistance, extending service life and improving production efficiency.

Building structures: used for bridge and frame supports to provide necessary strength and stability.

2014 aluminum rod buying guide

1.How to calculate the weight of aluminum bars when purchasing them in 2014

When purchasing aluminum bars on MASTAR, you can click [Calculator Service] to easily calculate the weight of 2014 aluminum bars.

2.What is the tolerance of 2014 aluminum bars?

The following are the various tolerances for the different forms of 2014 aluminum alloy; they are:

- Round pull rods – tolerance range is between 0.3 and 2.5 mm.

- Square pull rods - tolerance values range from 0.3 to 1.7 mm.

- Flat steel – Tolerance values range from 0.35 to 1.4 mm.

- Cold rolled sheet - tolerance values range from 0.03 to 0.22 mm.

3.2014 aluminum bar price

2014 aluminum bar price = (LME ingot price + processing fee) × weight + packaging fee + transportation fee

Please contact the sales staff to inquire about the price and processing fee per ton of various specifications of aluminum bars. The processing fee of 2014 aluminum bars of different sizes may vary greatly. We will provide you with the best quotation.

A92014-T4 Aluminum Bar, AA2014-T6 Aluminum Bar and EN AW-2014-T651 Aluminum Bar are the most commonly ordered products.

4.How to choose 2014 aluminum rod supplier/stockist?

When choosing a 2014 aluminum rod supplier, several factors must be considered to ensure you receive high-quality material and reliable service.

- Customized service: MASTAR can provide customized service according to customer needs. You only need to inform the length, quantity, surface finish, cutting, bending, color coating, end use and other special requirements.

- Competitive price: our products are priced competitively and we offer reasonable discounts for large quantities, giving you better prices and quality service.

- After-sales support: we provide fast after-sales support to ensure that you get timely help and support when using our products.

- Fast delivery: we have abundant inventory to ensure fast shipment of any product, saving time for your project.

| MASTAR 2014 aluminum rod partial stock hot selling products | |

| ASME SB 211 Aluminum 2014 T6 Flat Bar | Aluminum 2014 T6 Forged Rods |

| DIN 3.1255 / 3.1254 Aluminum 2014 Square Bar | ASTM/ASME B211 Aluminum 2014 T6 Hollow Bar |

| 2014 Aluminum T6 Black Bars | Aluminum 2014 T6 Cold Drawn Bar |

| Aluminium 2014 T6 Polish Bar | 2014 Aluminum T6 Round Rod |

| 2014A Aluminum T6 Hex Bar | Aluminum 2014 T6 Bright Rod |

| Aluminum 2014 T6 Welding Rods | Aluminum 2014 T6 Threaded Rods |

| Aluminum 2014 T6 Round Bars | AMS 4121 AA2014-T651 Forged Bars |

| UNS A92014 Aluminum 2014 Rods | AA2014-T651 Cold Finish Round Bar |

| ASTM B 211 Aluminum 2014 T6 Bars | Aluminum 2014 T6 Hexagonal Rods |

| Aluminium 2014 T6 Bright Bar | B211 2014 Aluminum Rectangular Bar |

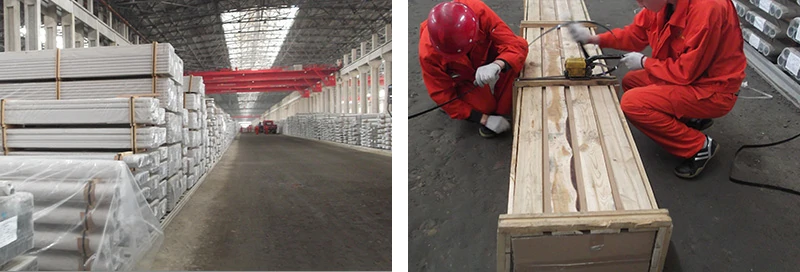

- Plastic or kraft paper packaging with moisture-proof desiccant inside.

- Mounted on wooden pallets, reinforced with steel straps and supplied with fumigation certificate.

- Meets GB/T3199 standard requirements.

- Packaging can be customized according to other customer requirements.

6.MASTAR 2014 aluminum rod product quality assurance

- There shall be no cracks, bubbles or corrosion spots on the surface of round bars, square bars and hexagonal bars.

- The surface of round bars, square bars or hexagonal bars shall not have deep scratches, wear, dents or straightening marks exceeding the tolerance range.

- Documents we provide include - Certificate of Origin, Invoice and PL certified by Chamber of Commerce, Test Certificate in accordance with EN10204 3.1 and other test reports (as per customer's request).

- Full traceability of 2014 aluminium bars and strips– the bars will be fully marked and the details can be linked to the test certificates.

MASTAR 2014 aluminum rod stock size reference table

Below are some of the stock sizes of MASTAR's 2014 aluminum bars. If you can't find the product that suits your needs, you can click Quick Quote to communicate with our sales staff about the specific product. All lengths can be cut.

| Diameter (inch) | Diameter (Metric) | Weight (KG/ Metre ) | Availability |

| 3/8" | (9.53mm) | 0.202 | Available |

| 1./2" | (12.7 mm) | 0.355 | Available |

| 5/8" | (15.88 mm) | 0.561 | Available |

| 3/4" | (19.05 mm) | 0.807 | Available |

| 7/8" | (22.23 mm) | 1.097 | Available |

| 1" | (25.4 mm) | 1.419 | Available |

| 1.1/8" | (28.58 mm) | 1.816 | Available |

| 1.1/4" | (31.75 mm) | 2.241 | Available |

| 1.3/8" | (34.93 mm) | 2.690 | Available |

| 1.1/2" | (38.1 mm) | 3.226 | Available |

| 1.5/8" | (41.28 mm) | 3.747 | Available |

| 1.3/4" | (44.45 mm) | 4.360 | Available |

| 2" | (50.8 mm) | 5.675 | Available |

| 2.1/4" | (57.15 mm) | 7.190 | Available |

| 2.1/2" | (63.5 mm) | 8.867 | Available |

| 2.3/4" | (69.85 mm) | 10.730 | Available |

| 3" | (76.2 mm) | 12.769 | Available |

| 3.1/4" | (82.5 mm) | 14.986 | Available |

| 3.1/2" | (88.9 mm) | 17.380 | Available |

| 3.3/4" | (95.25 mm) | 20.165 | Available |

| 4" | (101.6 mm) | 22.700 | Available |

| 4.1/4" | (107.95 mm) | 25.627 | Available |

| 4.1/2" | (114.3 mm) | 28.730 | Available |

| 5" | (127 mm) | 35.469 | Available |

| 5.1/4" | (133.35 mm) | 39.105 | Available |

| 5.1/2" | (139.7 mm) | 42.994 | Available |

| 6" | (152.4 mm) | 51.076 | Available |

| 6.1/2" | (165.1 mm) | 59.943 | Available |

| 7" | (177.8 mm) | 69.650 | Available |

| 8" | (203.2 mm) | 90.802 | Available |

| 9" | (228.6 mm) | 115.120 | Available |

| 10" | (254 mm) | 140.065 | Available |