7A09 aluminum tube is a high-strength aluminum alloy belonging to the aluminum-zinc-magnesium-copper alloy series. This alloy is often used in the aerospace field and is favored for its excellent strength, wear resistance and corrosion resistance. 7A09 aluminum alloy not only has excellent mechanical properties at room temperature, but also can maintain high strength in low temperature environment.

7A09 aluminum tube popular types

7A09 aluminum round tube

7A09 aluminum round tube- OD: 35mm- 225mm

- Advantages: mature technology, low cost

- Application: mainly used in aerospace structural parts, automobile chassis, bicycle frames and other occasions requiring high strength-to-weight ratio.

7A09 rectangular tube

7A09 rectangular tube- OD: 20mm - 200mm

- Advantages: space saving, strong toughness

- Application: used for building structures, mechanical equipment frames and lightweight vehicle structures.

7A09 seamless aluminum tube

7A09 seamless aluminum tube- OD: 8mm - 600mm

- Advantages: smoothness, straightness, high precision, etc.

- Application: equipment with high precision requirements, such as aerospace hydraulic systems and precision mechanical parts.

7A09 large diameter aluminum tube

7A09 large diameter aluminum tube- OD: 600mm and above, customizable

- Advantages: better bearing capacity, larger internal space

- Application: large building support structures, high-pressure pipelines in the ocean and oil industries.

7A09 aluminum round tube stock size

Below are the hot-selling 7A09 aluminum tube sizes in Mastar's inventory. If there is no size that matches your needs, please contact us and we will provide you with a solution based on our huge inventory advantage.

| Product | Temper | OD(mm) | Wall(mm) | Length(mm) |

| 7A09 aluminum round tube | T6 | 115mm | 5mm | 6000mm |

| 7A09 aluminum round tube | T6 | 145mm | 10mm | 3200mm |

| 7A09 aluminum round tube | T6 | 145mm | 13mm | 4000mm |

| 7A09 aluminum round tube | T6 | 155mm | 12.5mm | 6000mm |

| 7A09 aluminum round tube | T6 | 167mm | 24mm | 2200mm |

| 7A09 aluminum round tube | T6 | 175mm | 40mm | 2300mm |

| 7A09 aluminum round tube | T6 | 175mm | 40mm | 2500mm |

| 7A09 aluminum round tube | T6 | 180mm | 20mm | 3500mm |

| 7A09 aluminum round tube | T6 | 210mm | 45mm | 6000mm |

| 7A09 aluminum round tube | T6 | 210mm | 45mm | 2300mm |

| 7A09 aluminum round tube | T6 | 215mm | 20mm | 2770mm |

| 7A09 aluminum round tube | T6 | 220mm | 25mm | 2500mm |

| 7A09 aluminum round tube | T6 | 220mm | 50mm | 3200mm |

| 7A09 aluminum round tube | T6 | 220mm | 50mm | 6000mm |

| 7A09 aluminum round tube | T6 | 222mm | 41mm | 2420mm |

| 7A09 aluminum round tube | T6 | 222mm | 42mm | 2420mm |

| 7A09 aluminum round tube | T6 | 224mm | 42mm | 2000mm |

| 7A09 aluminum round tube | T6 | 235mm | 30mm | 2850mm |

| 7A09 aluminum round tube | T6 | 35mm | 3mm | 6000mm |

| 7A09 aluminum round tube | T6 | 50mm | 15mm | 6000mm |

| 7A09 aluminum round tube | T6 | 64mm | 13mm | 2300mm |

| 7A09 aluminum round tube | T6 | 80mm | 7.5mm | 6000mm |

Characteristics of 7A09 aluminum tube

- Good plasticity after solid solution treatment, and significant strengthening effect of heat treatment

- High strength below 150℃, especially good low temperature strength

- Poor welding performance

- There is a tendency for stress corrosion cracking and aluminum cladding or other protective treatments are required.

- Double-stage aging can improve resistance to stress corrosion cracking

- The plasticity in the annealed and freshly quenched states is slightly lower than that of 2A12 and better than that of 7A04

- The static fatigue performance, notch sensitivity and stress corrosion performance of the plate are better than 7A04

Chemical composition of 7A09 aluminum tube

| Elements | Composition(%) |

| Si | 0 – 0.50 |

| Cu | 1.2 – 2.0 |

| Mg | 2.0 – 3.0 |

| Zn | 5.1 – 6.1 |

| Mn | 0 – 0.15 |

| Ti | 0 – 0.10 |

| Cr | 0.16 - 0.30 |

| Fe | 0 – 0.5 |

| Al | Remainder |

| Other(each) | ≤ 0.05 |

| Other(total) | ≤ 0.10 |

Mechanical properties of 7A09 aluminum tube

| Temper | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) |

| T6 | 530MPa | 400MPa | 6% |

Production process of 7A09 aluminum tube

The production of 7A09 aluminum tube includes the following main steps:

Melting and casting: The raw materials are melted and cast into billets.

Extrusion or seamless processing: The billets are made into aluminum tubes by extrusion or seamless processing.

Heat treatment: T6 and T651 states require solution heat treatment and aging treatment.

Surface treatment: Anodizing can be performed to enhance corrosion resistance.

Other knowledge about 7A09 aluminum tube

What is the difference between 7A09-T6 and 7A09-T651?

T6 is a solution heat treated state, while T651 includes stress relief after heat treatment.

Can 7A09 aluminum alloy be welded?

7A09 has poor weldability, so welding is usually avoided in critical applications.

Which industries can benefit most from 7A09 aluminum alloy?

Mainly including the aerospace, automotive industry and high-performance sports equipment industries.

How does 7A09 compare to 7075 aluminum alloy?

Both have high strength properties, but 7A09 is more favored in terms of low temperature performance.

Why choose Mastar?

- Customized service: Provide a variety of specifications and surface treatments to meet the personalized needs of customers.

- Complete certification: All products are certified by ISO, CE and other international standards to ensure reliable product quality.

- Fast delivery: Sufficient inventory, short delivery time, to meet the needs of urgent orders.

- Quick response: Respond to customer demands and quotations quickly, and give customers the most competitive prices

- Price update: According to the international aluminum price, update the price for customers in real time to let customers know the latest price.

- Free samples: All samples can be provided free of charge, and customers can place orders after passing the test.

Mastar 7A09 aluminum tube purchasing guide

Before buying 7A09 Aluminum Tube from Mastar, please confirm the size and quantity you need. Then, contact our customer service team and we will provide you with the best quality products and the most competitive market prices.

7A09 aluminum tube price

7A09 aluminum tube price: (LME ingot price + processing fee) × weight + packaging fee + transportation fee

Please contact Mastar for price and processing fee per ton of various specifications of aluminum tubes. The processing fee of 7A09 aluminum tubes of different sizes may vary greatly, and we will provide you with the best quotation.

7A09-T6 aluminum tube is the most common ordering temper.

7A09 aluminum tube appearance quality

The appearance quality requirements of 7A09 aluminum tubes are very strict, especially in aviation and high-stress applications, ensuring the surface quality is directly related to its performance and safety. The following are the appearance quality standards and requirements of 7A09 aluminum tubes:

Surface finish: The surface of 7A09 aluminum tubes should be smooth, without obvious mechanical damage, cracks, burrs or pits. The inner and outer surfaces of seamless aluminum tubes should be clean and uniform, especially when used in the aviation field, requiring a high finish to ensure aerodynamic performance and corrosion resistance

No welding marks: Due to the production process requirements of seamless aluminum tubes, no welding marks is a major feature. 7A09 aluminum tubes are produced by extrusion or perforation processes, which ensures the integrity of the material and reduces structural defects caused by welding

Anti-oxidation and anti-corrosion treatment: In order to ensure long-term exposure to harsh environments without corrosion, 7A09 aluminum tubes are usually anodized, which not only improves the oxidation resistance of the tube, but also enhances the surface hardness and wear resistance. In addition, this treatment can give the tube a beautiful appearance and increase its service life

Color consistency: The surface color of 7A09 aluminum tubes should be uniform and consistent, and there should be no obvious color difference. The anodized 7A09 aluminum tube has a more uniform color and avoids quality problems caused by uneven surface during the use of aluminum.

Defect control: Common appearance defects such as scratches, indentations, oxidation spots, peeling, etc. must be strictly controlled during the production process of 7A09 aluminum tubes. Especially when used in aviation, aerospace and high-performance products, any surface defects may affect its strength and service life, so strict quality inspection procedures are usually required, including visual inspection and non-destructive testing.

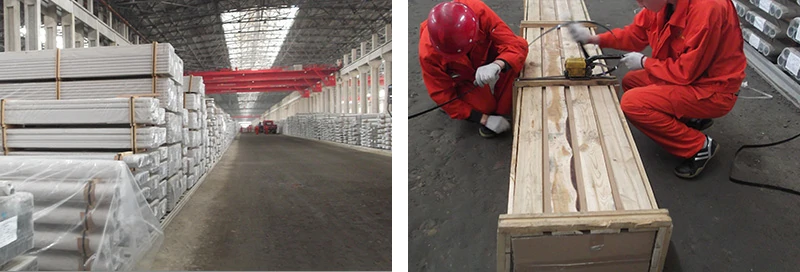

7A09 aluminum tube packaging

Plastic or kraft paper packaging with moisture-proof desiccant inside.

Mounted on wooden pallets, reinforced with steel straps, and provided with fumigation certificate.

Complies with GB/T3199 standard requirements.

Packaging can be customized according to other customer requirements.