7075 aluminum tube, widely used in aerospace, automotive, and marine industries, is known for its excellent strength-to-weight ratio and machinability. It excels in high-strength, lightweight structural parts, offering reliable support under extreme conditions, with great fatigue strength and wear resistance.

MASTAR 7075 aluminum round tube product catalog

MASTAR's 7075 aluminum round tubes come in various specifications, including cold-drawn seamless, high-strength extruded, large-diameter, structural, and anodized corrosion-resistant tubes, all with strict quality control for excellent performance and reliability.

7075 cold drawn seamless aluminum round tube OD: 0.2" - 11.81 " (5 - 300 mm)

7075 cold drawn seamless non-hydraulic aluminum round tube has extremely high strength and excellent mechanical properties. It is suitable for structural parts that require lightweight and high strength, especially in scenarios that require extremely high precision and durability.

7075 large diameter seamless aluminum round tube— recommended maximum 1320mm

It is suitable for large-scale structural parts and scenes that require a combination of large size and high strength, providing excellent strength and stability. It adopts a unique vertical extrusion patented technology, welcome to consult.

7075 extruded seamless aluminum round tube OD: 0.314"-16.54"(3-420mm)

7075 extruded seamless aluminum round tube, with its excellent fatigue resistance and high strength, is suitable for structural parts under dynamic loads or scenes with high strength requirements.

7075 extruded structure aluminum round tube Wall: 0.032"-0.55"(5-50mm)

7075 extruded structural aluminum round tube has excellent strength-to-weight ratio and deformation resistance. It is suitable for structural components that bear high loads and require lightweight, and meet the needs of complex designs and harsh conditions.

7075 aluminum alloy forged round tube OD: 7.87"-39.37"(200-1000mm)

7075 aluminum alloy forged round tube is a product known for its high strength and durability. Through the forging process, this round tube has reached extremely high levels of strength and fatigue resistance, making it an ideal material for demanding applications.

7075 anodized aluminum round tube

The surface of 7075 anodized aluminum round tube is anodized, which has excellent corrosion resistance and beautiful appearance. It is suitable for scenes with special requirements on appearance and durability, providing longer service life and decorative effect.

The preferred material in high-strength industry—7075 aluminum round tube

7075 aluminum has become the preferred material in high-strength industry due to its excellent strength and relative lightness. It performs well under huge stress and extreme conditions to ensure structural stability. Especially forged 7075 aluminum round tube, its strength is almost twice that of 6061-T6 aluminum, close to most titanium tube alloys, and it is the strongest aluminum product in the world.

7075 aluminum round tube and aerospace

7075 aluminum round tube and aerospace- Application: Hydraulic system pipelines, landing gear struts, wing reinforcement tubes

- High strength and lightweight properties enable it to withstand extreme stress, ensuring flight safety and structural stability.

7075 aluminum round tube and national defense industry

7075 aluminum round tube and national defense industry- Application: Tank barrel lining tube, armored vehicle transmission shaft tube, weapon system support tube

- Provide extremely high strength and durability to adapt to harsh combat environments.

7075 aluminum round tube and heavy machinery

7075 aluminum round tube and heavy machinery- Application: used for hydraulic cylinder tubes, support column tubes, rotating shaft tubes in excavators and cranes.

- Guaranteed long-term performance under heavy load and high stress conditions.

7075 aluminum round tube and automobile industry

7075 aluminum round tube and automobile industry- Applications: Drive shaft tubes, shock absorber housing tubes, frame support tubes for racing and high-performance vehicles.

- Reduce vehicle weight while enhancing impact resistance.

7075 aluminum round tube and outdoor products and sports equipment

7075 aluminum round tube and outdoor products and sports equipment- Application: frame main tube, support rod tube of mountaineering equipment, reinforcement bracket tube of skis.

- High strength and high wear resistance, improving the performance and durability of sports equipment.

5 key tips to ensure you choose the top-grade 7075 aluminum round tube

1.Material purity and composition: The alloy composition of the aluminum tube must meet the standards. Material purity directly affects product performance and service life.

| MASTAR 7075 aluminum tube chemical composition reference table | |

| Aluminum (Al) | 86.9 to 91.4 |

| Zinc (Zn) | 5.1 to 6.1 |

| Magnesium (Mg) | 2.1 to 2.9 |

| Copper (Cu) | 1.2 to 2.0 |

| Iron (Fe) | 0 to 0.5 |

| Chromium (Cr) | 0.18 to 0.28 |

| Silicon (Si) | 0 to 0.4 |

| Manganese (Mn) | 0 to 0.3 |

| Zirconium (Zr) | 0 to 0.25 |

| Titanium (Ti) | 0 to 0.2 |

| Residuals | 0 to 0.15 |

2.Mechanical properties, strength and thermal properties: can provide tensile, hardness, bending and other test results, and provide mechanical properties test certificates.

| Temper | Ultimate Tensile Strength MPa | Yield Tensile Strength MPa | Fatigue Strength MPa | Elongation at Break % |

| 7075-T6 | 560 | 480 | 160 | 7.9 |

| 7075-T651 | 550 | 460 | 160 | 8.2 |

| 7075-T6511 | 510 | 580 | 180 | 5.6 |

| 7075-T73 | 500 | 410 | 160 | 7.1 |

| 7075-T7351 | 510 | 410 | 160 | 7.5 |

| 7075-T73511 | 510 | 420 | 170 | 8.0 |

| 7075-T76 | 560 | 480 | 190 | 7.9 |

| 7075-T7651 | 550 | 470 | 190 | 7.3 |

| 7075-T76511 | 560 | 500 | 190 | 6.7 |

| 7075-T62 | 560 | 460 | 170 | 7.2 |

| Note: The above values are for reference only. Please contact our salesperson for specific parameters. | ||||

3.Dimensional accuracy and tolerance control: Ensure that the key dimensional tolerances of the aluminum tube, such as outer diameter, wall thickness, and cutting, meet the standards.

The outer diameter and wall thickness can be produced according to different product standards, in accordance with the tolerance requirements of ASTM B221, EN 755-9, AMS-QQ-A-200/11, AMS-WWT-700/7, EN 754-1, ASTM B483, ASTM B241, ASTM B210 and other standards. The cutting tolerance can be referred to the table below, or according to customer requirements:

| 7075 Aluminum Round Tube Cutting Tolerance | |

| Length | Cutting Tolerance |

| By the lnch | Plus 1/8", Minus 0 |

| 12" | Plus or Minus 1/4" |

| 18" | Plus or Minus 1/4" |

| 24" | Plus or Minus 1/2" |

| 36" | Plus or Minus 1/2" |

| 48" | Plus or Minus 3/4" |

| 60" | Plus or Minus 3/4" |

| 72" | Plus or Minus 1" |

4.Surface finish and defect detection: Check the surface finish of the aluminum tube to avoid defects such as cracks, pores, and dents that affect the appearance and performance of the product.

5.Corrosion resistance and protective treatment: Aluminum tubes have good corrosion resistance, especially when used in harsh environments, and can be provided with surface treatment or special protection.

Why MASTAR is the preferred supplier of 7075 aluminum round tube

- Fast delivery: We have abundant inventory to ensure fast shipment of any product, saving time for your project.

- Customized service: MASTAR can provide customized service according to customer needs. You only need to inform the length, quantity, surface finish, cutting, bending, color coating, end use and other special requirements.

- Competitive price: our products are priced competitively and we offer reasonable discounts for large quantities, giving you better prices and quality service.

- After-sales support: we provide fast after-sales support to ensure that you get timely help and support when using our products.

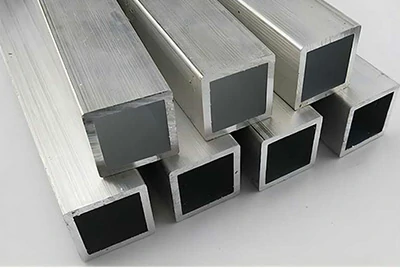

MASTAR other hot selling 7075 aluminum tube products

MASTAR 7075 aluminum round tube stock size metric

| Alloy Temper | OD/mm | Wall thickness/mm | ID/mm | Length |

| 7075-T6 seamless tube | 18 | 6 | 6 | 4.02 meter |

| 7075-T6 seamless tube | 19 | 4 | 11 | 4.02 meter |

| 7075-T6 seamless tube | 30 | 10 | 10 | 4.02 meter |

| 7075-T6 seamless tube | 35 | 5 | 25 | 4.02 meter |

| 7075-T6 seamless tube | 40 | 5 | 30 | 4.02 meter |

| 7075-T6 seamless tube | 45 | 5 | 35 | 4.02 meter |

| 7075-T6 seamless tube | 50 | 5 | 40 | 4.02 meter |

| 7075-T6 seamless tube | 50 | 15 | 20 | 4.26 meter |

| 7075-T6 seamless tube | 55 | 5 | 45 | 4.02 meter |

| 7075-T6 seamless tube | 60 | 5 | 50 | 4.02 meter |

| 7075-T6 seamless tube | 60 | 10 | 40 | 4.02 meter |

| 7075-T6 seamless tube | 60 | 20 | 20 | 5.02 meter |

| 7075-T6 seamless tube | 65 | 5 | 55 | 4.02 meter |

| 7075-T6 seamless tube | 65 | 10 | 45 | 4.02 meter |

| 7075-T6 seamless tube | 65 | 15 | 35 | 5.02 meter |

| 7075-T6 seamless tube | 70 | 5 | 60 | 4.02 meter |

| 7075-T6 seamless tube | 70 | 15 | 40 | 4.21 meter |

| 7075-T6 seamless tube | 75 | 15 | 45 | 4.02 meter |

| 7075-T6 seamless tube | 85 | 10 | 65 | 4.02 meter |

| 7075-T6 seamless tube | 85 | 15 | 55 | 4.02 meter |

| 7075-T6 seamless tube | 90 | 5 | 80 | 4.02 meter |

| 7075-T6 seamless tube | 90 | 10 | 70 | 4.02 meter |

| 7075-T6 seamless tube | 90 | 15 | 60 | 4.02 meter |

| 7075-T6 seamless tube | 90 | 30 | 30 | 3 meter |

| 7075-T6 seamless tube | 95 | 5 | 85 | 4.02meter |

| 7075-T6 seamless tube | 100 | 5 | 90 | 3 meter |

| 7075-T6 seamless tube | 100 | 15 | 70 | 4.10 meter |

| 7075-T6 seamless tube | 100 | 20 | 60 | 4.02 meter |

| 7075-T6 seamless tube | 100 | 30 | 40 | 4.02 meter |

| 7075-T6 seamless tube | 105 | 20 | 65 | 4.02 meter |

| 7075-T6 seamless tube | 110 | 10 | 90 | 4.02 meter |

| 7075-T6 seamless tube | 110 | 15 | 80 | 4.08 meter |

| 7075-T6 seamless tube | 110 | 25 | 60 | 4.02 meter |

| 7075-T6 seamless tube | 115 | 15 | 85 | 4.02 meter |

| 7075-T6 seamless tube | 115 | 20 | 75 | 4.02 meter |

| 7075-T6 seamless tube | 120 | 10 | 100 | 4.30 meter |

| 7075-T6 seamless tube | 120 | 20 | 80 | 4.02 meter |

| 7075-T6 seamless tube | 120 | 30 | 60 | 4.02 meter |

| 7075-T6 seamless tube | 125 | 10 | 105 | 4.07 meter |

| 7075-T6 seamless tube | 125 | 15 | 95 | 4.02 meter |

| 7075-T6 seamless tube | 125 | 20 | 85 | 4.02 meter |

| 7075-T6 seamless tube | 130 | 15 | 100 | 4.02 meter |

| 7075-T6 seamless tube | 130 | 25 | 80 | 4.02 meter |

| 7075-T6 seamless tube | 130 | 30 | 70 | 4.05 meter |

| 7075-T6 seamless tube | 135 | 10 | 115 | 4.02 meter |

| 7075-T6 seamless tube | 135 | 15 | 105 | 4.03 meter |

| 7075-T6 seamless tube | 135 | 20 | 95 | 4.18 meter |

| 7075-T6 seamless tube | 140 | 15 | 110 | 4.02 meter |

| 7075-T6 seamless tube | 140 | 20 | 100 | 4.27 meter |

| 7075-T6 seamless tube | 140 | 30 | 80 | 4.17 meter |

| 7075-T6 seamless tube | 140 | 40 | 60 | 4.23 meter |

| 7075-T6 seamless tube | 150 | 10 | 130 | 4.31 meter |

| 7075-T6 seamless tube | 150 | 15 | 120 | 4.02 meter |

| 7075-T6 seamless tube | 150 | 20 | 110 | 4.02 meter |

| 7075-T6 seamless tube | 150 | 25 | 100 | 4.02 meter |

| 7075-T6 seamless tube | 150 | 30 | 90 | 4.02 meter |

| 7075-T6 seamless tube | 150 | 40 | 70 | 4.02 meter |

| 7075-T6 seamless tube | 160 | 15 | 130 | 4.02 meter |

| 7075-T6 seamless tube | 160 | 20 | 120 | 4.02 meter |

| 7075-T6 seamless tube | 160 | 25 | 110 | 4.02 meter |

| 7075-T6 seamless tube | 160 | 30 | 100 | 4.22 meter |

| 7075-T6 seamless tube | 160 | 40 | 80 | 4.04 meter |

| 7075-T6 seamless tube | 160 | 50 | 60 | 4.02 meter |

| 7075-T6 seamless tube | 170 | 10 | 150 | 4.02 meter |

| 7075-T6 seamless tube | 170 | 15 | 140 | 4.02 meter |

| 7075-T6 seamless tube | 170 | 20 | 130 | 4.02 meter |

| 7075-T6 seamless tube | 170 | 25 | 120 | 4.02 meter |

| 7075-T6 seamless tube | 170 | 40 | 90 | 4.19 meter |

| 7075-T6 seamless tube | 170 | 50 | 70 | 4.06 meter |

| 7075-T6 seamless tube | 180 | 10 | 160 | 3.5-4 meter |

| 7075-T6 seamless tube | 180 | 15 | 150 | 3.3-4 meter |

| 7075-T6 seamless tube | 180 | 20 | 140 | 3.7 meter |

| 7075-T6 seamless tube | 180 | 30 | 120 | 4 meter |

| 7075-T6 seamless tube | 180 | 40 | 100 | 4.20 meter |

| 7075-T6 seamless tube | 180 | 50 | 80 | 3-4 meter |

| 7075-T6 seamless tube | 190 | 10 | 170 | 3.41-4meter |

| 7075-T6 seamless tube | 190 | 15 | 160 | 3-4meter |

| 7075-T6 seamless tube | 190 | 20 | 150 | 3 meter |

| 7075-T6 seamless tube | 190 | 30 | 130 | 4 meter |

| 7075-T6 seamless tube | 190 | 40 | 110 | 3-3.9 meter |

| 7075-T6 seamless tube | 200 | 10 | 180 | 3.8-4 meter |

| 7075-T6 seamless tube | 200 | 15 | 170 | 3.2-4 meter |

| 7075-T6 seamless tube | 200 | 20 | 160 | 3.59-3.71 meter |

| 7075-T6 seamless tube | 200 | 25 | 150 | 3.7-4 meter |

| 7075-T6 seamless tube | 200 | 30 | 140 | 3.11-4 meter |

| 7075-T6 seamless tube | 200 | 40 | 120 | 3.72 meter |

| 7075-T6 seamless tube | 200 | 50 | 100 | 4.24 meter |

| 7075-T6 seamless tube | 210 | 20 | 170 | 3.1-4 meter |

| 7075-T6 seamless tube | 210 | 30 | 150 | 3.01-3.07 meter |

| 7075-T6 seamless tube | 210 | 40 | 130 | 3.41-3.64 meter |

| 7075-T6 seamless tube | 210 | 50 | 110 | 2-2.88 meter |

| 7075-T6 seamless tube | 220 | 30 | 160 | 3.4-4 meter |

| 7075-T6 seamless tube | 220 | 40 | 140 | 3-3.64 meter |

| 7075-T6 seamless tube | 220 | 50 | 120 | 2.22-2.6 meter |

| 7075-T6 seamless tube | 230 | 20 | 190 | 3.5 meter |

| 7075-T6 seamless tube | 230 | 30 | 170 | 3.01-3.7 meter |

| 7075-T6 seamless tube | 230 | 40 | 150 | 2.6 meter |

| 7075-T6 seamless tube | 230 | 50 | 130 | 2-2.62 meter |

| 7075-T6 seamless tube | 240 | 20 | 200 | 4 meter |

| 7075-T6 seamless tube | 240 | 30 | 180 | 3.01-3.6 meter |

| 7075-T6 seamless tube | 240 | 40 | 160 | 2-2.6 meter |

| 7075-T6 seamless tube | 240 | 50 | 140 | 2-2.54 meter |

| 7075-T6 seamless tube | 250 | 20 | 210 | 3-4 meter |

| 7075-T6 seamless tube | 250 | 30 | 190 | 3.2-3.6 meter |

| 7075-T6 seamless tube | 250 | 40 | 170 | 2.41-2.54 meter |

| 7075-T6 seamless tube | 250 | 50 | 150 | 2 meter |

| 7075-T6 seamless tube | 260 | 30 | 200 | 2.4-2.62 meter |

| 7075-T6 seamless tube | 260 | 40 | 180 | 2.6 meter |

| 7075-T6 seamless tube | 260 | 50 | 160 | 1.8 meter |

Click to see all

Click to see all MASTAR 7075 aluminum round tube hot sale size INCH

| Description | OD/in | WA/in | |

| 7075-T6 Tube AMS-WW-T-700/7 3/8 OD X 0.049"WA | 0.375 | 3/8 | 0.038 |

| 7075-T6 Tube AMS-WW-T-700/7, ASTM B210 1/2 OD X 0.056"WA | 0.500 | 1/2 | 0.056 |

| 7075-T6 Tube AMS-WW-T-700/7 5/8 OD X 0.049"WA | 0.625 | 5/8 | 0.049 |

| 7075-T6 Tube AMS-WW-T-700/7 3/4 OD X 0.050"WA | 0.750 | 3/4 | 0.056 |

| 7075-T6 Tube AMS-WW-T-700/7 1"OD X 0.065"WA | 1,000 | 1 | 0.065 |

| 7075-T6 Tube AMS-WW-T-700/7 1"OD X 0.049"WA | 1,000 | 1 | 0.049 |

| 7075-T6 Tube AMS-WW-T-700/7 1 1/8 OD X 0.156"WA | 1,130 | 1 1/8 | 0.156 |

| 7075-O Tube AMS-WW-T-700/7 1 1/4 OD X 0.049"WA | 1,250 | 1 1/4 | 0.049 |

| 7075-T6 Tube AMS-WW-T-700/7 1 1/4 OD X 0.056"WA | 1,250 | 1 1/4 | 0.056 |

| 7075-T6 Tube AMS-WW-T-700/7 1 1/4 OD X 0.065"WA | 1,250 | 1 1/4 | 0.065 |

| 7075-T6 Tube AMS-WW-T-700/7 1 3/7 OD X 0.090"WA | 1,420 | 1 3/7 | 0.090 |

| 7075-T6 Tube AMS-WW-T-700/7, ASTM B210 1 1/2 ODX 0.156"WA | 1,500 | 1 1/2 | 0.156 |

| 7075-T6 Tube AMS-WW-T-700/7, ASTM B210 1 1/2 ODX 0.125"WA | 1,500 | 1 1/2 | 0.125 |

| 7075-T6 Tube AMS-WW-T-700/7, ASTM B210 1 3/4 ODX 0.150"WA | 1.750 | 1 3/4 | 0.150 |

| 7075-T6 Tube AMS-WW-T-700/7, ASTM B210 1 3/4 ODX 0.125"WA | 1.750 | 1 3/4 | 0.125 |

| 7075-T73511 Tube AMS-QQ-A-200/11 2"OD X 0.250"WA | 2.000 | 2 | 0.250 |

| 7075-T6511 Tube AMS-QQ-A-200/11 2"OD X 0.375"WA | 2.000 | 2 | 0.250 |

| 7075-T6 Tube AMS-WW-T-700/7, ASTM B210 1 3/4 ODX 0.375"WA | 2.500 | 2 1/2 | 0.375 |

| 7075-T73 Tube AMS-WW-T-700/7, ASTM B210 2 3/4 OD X 0.085"WA | 2.750 | 2 3/4 | 0.085 |

| 7075-T6 Tube AMS-WW-T-700/7, ASTM B210 3" OD X 0.35"WA | 3.000 | 3 | 0.350 |

| 7075-T6 Tube AMS-WW-T-700/7, ASTM B210 4 1/2 OD X 0.100"WA | 4.500 | 4 1/2 | 0.100 |

Click to see all

Click to see all FAQs on purchasing 7075 aluminum round tube

Is 7075 aluminum tube expensive?

The price of the material is the result of a number of factors. Copper and zinc are added to enhance the strength of the material. Part of the cost factor also includes the complex seamless pipe indirect extrusion that the product must undergo before it is ready for sale. There are various strictly controlled processes, including heat treatment. All in all, 7075 seamless pipe is very reliable, so it is reasonable that it is a little more expensive than many other alternative materials.

What are the issues that need to be paid attention to in the design of 7075 aluminum tubes in high-pressure projects?

- Importance of design elements: The choice of size and material is critical to the safety and functionality of the system.

- The criticality of seamless pipes: The seamless structure ensures integrity under high pressure.

- OD vs. Wall Thickness: Selecting the proper OD and wall thickness combination is critical to ensuring the integrity of your piping system.

- Tempering state of the alloy: Select the appropriate tempering state according to the project requirements to meet specific performance needs.

- Quality Control: Make sure the manufacturer has strict quality control to eliminate any defects in the material and prevent weak points.

Do I need to take more precautions with 7075 seamless pipe for marine applications?

There is no doubt that 7075 aluminum seamless pipe has good corrosion resistance and can work reliably in corrosive environments. However, if it is overly exposed to these conditions, more measures may need to be taken, although this is a precautionary measure. We can provide anodizing treatment, which will extend the service life. Polyurethane coating, epoxy coating and other special surface treatments that are more effective for marine conditions can also be considered.

How does 7075 aluminum tubing perform at high temperatures?

Our 7075 seamless tubes excel at high temperatures, so you can use them with confidence in high-temperature applications. This alloy has a melting point of at least 477°C and a thermal conductivity of 130 W/ mK , two key properties that help maintain reliable performance levels in extreme temperatures. Users of 7075 tubes in industrial and aerospace applications often use 7075 aluminum tubes to build aircraft when the application temperature exceeds normal temperatures. However, be aware of the high-temperature limits of the product, as the material loses its mechanical properties beyond these limits.

How does 7075 seamless pipe compare to steel and other alternative materials?

7075 seamless tubing has several advantages over these materials, which is why this material is widely used in the industry. For example, the strength-to-weight ratio. In this regard, 7075 aluminum extrusions outperform other materials, so users use it in projects that require both strength and light weight. The versatility of 7075 aluminum tubing is something that is not common or comparable to other alternative materials. Versatility refers to the ability of these tubes to be formed and processed. Add to that the high corrosion resistance of 7075 material, and you can see why there are not many alternative materials that can be better.

Click to collapse

Click to collapse