6105 aluminum is a less common wrought alloy that belongs to the aluminum-magnesium-silicon family or 6000 series aluminum. The alloy is formed by extrusion and is usually in heated form. 6105 aluminum consists primarily of magnesium and silicon and is used to make other wrought products.

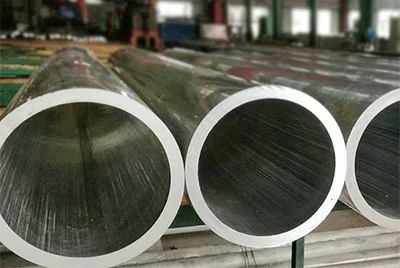

MASTAR 6105 aluminum tube product introduction

Product types in stock: Extruded tube, forged tube, round tube, square tube, flat tube ...

Schedule: SCH20, SCH30, SCH40, STD, SCH80, XS, SCH60, SCH80, SCH120, SCH140, SCH160, XXS

Length: Can be cut to any length.

Surface treatment: mill finish, anodized, bright, black, polished …

Aluminum tube ends: flat end, bevel end, threaded end

6105 aluminum equivalent names: UNS A96105; Aluminium 6105; AA6105; Al6105; EN AW-6105

MASTAR 6105 aluminum tube hot selling products

6105 T1 aluminum tube

6105 T1 aluminum tube- T1 is natural aging, 6105 aluminum tube in T1 state has good strength and corrosion resistance, and is most suitable for bending. Suitable for structural parts requiring high strength, such as transportation vehicles and industrial equipment.

6105 T5 aluminum tube

6105 T5 aluminum tube- Aluminum alloy tubes that have been artificially aged provide excellent mechanical properties and increased strength, can be brazed or welded by a variety of commercial methods, and are compatible with a variety of aluminum anodizing processes, including clear, transparent and colored, and hard coating. Commonly used in architectural and engineering applications.

6105 extruded tube

6105 extruded tube- Aluminum tubes produced through the extrusion process have good forming ability and uniform wall thickness, and are widely used in various manufacturing and structural applications.

6105 forged pipe

6105 forged pipe- Outer diameter: 200-1000mm; Wall thickness: 20-100mm

- It is processed by forging process and has excellent strength and toughness, suitable for applications with high load and high strength requirements.

MASTAR 6105 aluminum tube supply shapes

- 6105 aluminum round tube

- 6105 aluminum square tube

- 6105 aluminum flat tube

- 6105 rectangular tube

- 6105 hexagonal tube

- 6105 Other custom extruded tubes

6105 aluminum tube chemical composition

| Element | Component % |

| Aluminum (Al) | 97.2 to 99 |

| Silicon (Si) | 0.6 to 1.0 |

| Magnesium (Mg) | 0.45 to 0.8 |

| Iron (Fe) | 0 to 0.35 |

| Manganese (Mn) | 0 to 0.1 |

| Chromium (Cr) | 0 to 0.1 |

| Titanium (Ti) | 0 to 0.1 |

| Zinc (Zn) | 0 to 0.1 |

| Copper (Cu) | 0 to 0.1 |

| Residuals | 0 to 0.15 |

6105 aluminum tube mechanical properties reference table

| Temper | Elastic (Young's, Tensile) Modulus | Elongation at Break | Fatigue Strength | Tensile Strength: Ultimate (UTS) | Tensile Strength: Yield (Proof) |

| 6105-T1 | 68 GPa | 16 % | 95 MPa | 190 MPa | 120 MPa |

| 9.9 x 106 psi | 14 x 10 3 psi | 28 x 10 3 psi | 17 x 10 3 psi | ||

| 6105-T5 | 68 GPa | 9% | 130 MPa19 x 103 psi | 280 MPa41 x 103 psi | 270 MPa40 x 103 psi |

| 9.9 x 10 6 psi | 130 MPa19 x 103 psi | 280 MPa41 x 103 psi | 270 MPa40 x 103 psi |

6105 aluminum tube and 6061 aluminum tube

6105 aluminum and 6061 aluminum are very similar, except that 6105 aluminum contains more silicon. 6105 aluminum is preferred over 6061 aluminum, especially for complex shapes, because it is easier to extrude and is less sensitive to quenching. When manufactured in the T5 temper specification, 6105 aluminum has a similar yield strength and tensile strength to 6061-T6 aluminum.

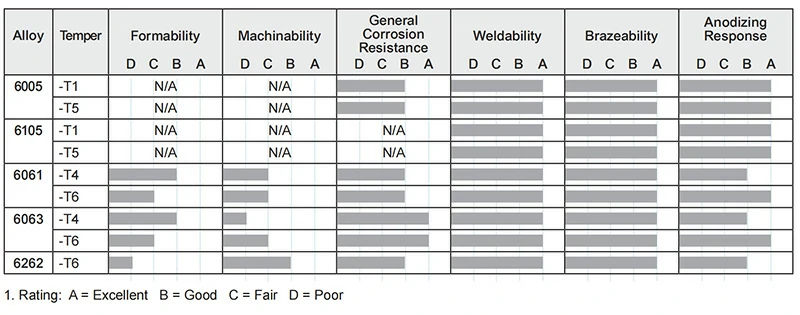

How to choose the right alloy for extrusion——6061, 6063, 6005, 6105, 6262, 6463

Although many alloys in the 6000 series can be used to make extrusions, not all alloys are equally suitable for all jobs. Manufacturers must select an alloy with the correct properties for their specific product.

- Aluminum 6105 is an alloy of magnesium and silicon that offers good formability and weldability and is commonly used in wrought products for areas such as architecture, construction, fixtures and displays, especially where strength and finishing are required.

- 6061 aluminum has excellent strength, corrosion resistance, workability and weldability and is commonly used in construction, aerospace, automotive, marine and welded parts, especially for applications requiring structural strength and durability.

- 6063 aluminum, as a "construction alloy", is known for its good corrosion resistance, formability and surface treatment. It is widely used in door and window frames, display racks, irrigation pipes and complex extrusions, commonly seen in the construction and advertising industries.

- Aluminum 6005 has excellent extrusion performance, strength, formability and weldability, as well as good surface finish, but poor impact resistance. It is suitable for manufacturing forged products and is commonly used in buildings, construction, ladders, platforms, ships and frames, etc. Where finishing and strength are required.

- Aluminum 6463 is famous for its bright mirror-like surface and excellent formability and processability. It is often used in shower rooms, photo frames, car decorations, display advertisements and other occasions that require exquisite appearance.

- Aluminum 6262 has good machinability, corrosion resistance and medium strength. It is easy to machine and is often used in the manufacture of parts requiring high precision, such as bolts, screws, joints and automotive parts. It is suitable for applications requiring good cutting performance.

MASTAR 6105 aluminum tube performance

- Corrosion resistance: 6105 aluminum tube has excellent corrosion resistance and can resist the attack of most organic acids such as acetic acid and citric acid. Compared with other aluminum alloys with similar strength, it shows good corrosion resistance, but long-term exposure to strong alkaline or oxidizing environment may cause pitting or stress corrosion cracking.

- Heat resistance: 6105 aluminum tube has excellent heat resistance, with a melting point between 500°C – 600°C (932°F – 1112°F). It can maintain its mechanical properties at high temperatures and is suitable for applications that require high temperature durability.

- Heat Treatment: 6105 aluminum tube can be heat treated by solution heat treatment (SHT) or artificial aging (AA) to adjust the hardness, strength, ductility or toughness to meet different application requirements.

- Machinability: Due to its high strength and hardness, 6105 aluminum is suitable for machining with carbide tools, and the use of coolant is recommended to extend tool life and reduce wear.

- Weldability: Welding 6105 aluminum tubes requires preheating and the use of 4043 or 5356 aluminum filler rods. Post-heating treatment is required after welding to avoid cracks caused by improper cooling.

MASTAR 6105 aluminum tube cooperation areas

- ladder

- Seamless structural pipe

- Automotive Connector Stock

- Handrail tube

Why MASTAR is the preferred supplier of 6105 aluminum tube

- Fast Delivery: We have abundant inventory to ensure fast shipment of any product, saving time for your project.

- Customized service: MASTAR can provide customized service according to customer needs. You only need to inform the length, quantity, surface finish, cutting, bending, color coating, end use and other special requirements.

- Competitive Price: Our products are priced competitively and we offer reasonable discounts for large quantities, giving you better prices and quality service.

- After-sales support: We provide fast after-sales support to ensure that you get timely help and support when using our products.