The 6026 aluminum tube is a new environmentally friendly aluminum alloy that complies with European environmental protection directives.

It features excellent corrosion resistance and machinability, making it particularly suitable for applications in the automotive and electrical industries.

Additionally, its tin-free characteristic helps prevent cracking issues under high temperatures and pressure.

Specifications of 6026 aluminum tubes

- EN 755

- EN 573

- EN 754

- ASTM B221

Product classification of 6026 aluminum tubes

Stock size range of 6026 aluminum tube

6026 Aluminum Round Tubes

6026 Aluminum Round Tubes- Diameters: 6 mm - 250 mm

- Wall Thickness: 1 mm - 10 mm

- Length: 1 - 6 m

6026 Aluminum Square Tubes

6026 Aluminum Square Tubes- Side Length: 10 mm - 150 mm

- Wall Thickness: 1 mm - 5 mm

- Length: 1 - 6 m

6026 Aluminum Rectangular Tubes

6026 Aluminum Rectangular Tubes- Width × Height: 10 mm × 20 mm - 100 mm × 200 mm

- Wall Thickness: 1 mm - 6 mm

- Length: 1 - 6 m

Chemical composition of 6026 aluminum tube

| Chemical Element | % Present |

| Manganese (Mn) | 0.20 - 1.00 |

| Iron (Fe) | 0.0 - 0.70 |

| Magnesium (Mg) | 0.60 - 1.20 |

| Silicon (Si) | 0.60 - 1.40 |

| Copper (Cu) | 0.20 - 0.50 |

| Lead (Pb) | 0.0 - 0.40 |

| Bismuth (Bi) | 0.50 - 1.50 |

| Zinc (Zn) | 0.0 - 0.30 |

| Tin (Sn) | 0.0 - 0.05 |

| Chromium (Cr) | 0.0 - 0.30 |

| Titanium (Ti) | 0.0 - 0.20 |

| Other (Each) | 0.05 max |

| Others (Total) | 0.15 max |

| Aluminium (Al) | Balance |

Physical properties of 6026 aluminum tube

| Physical Property | Value |

| Density | 2.72 g/cm³ |

| Thermal Expansion | 23.4 x10^-6 /K |

| Modulus of Elasticity | 69 GPa |

| Thermal Conductivity | 172 W/m.K |

| Electrical Resistivity | 0.039 x10^-6 Ω .m |

Equivalent specifications of 6026 aluminum tubes

- A95754

- Al 3.1Mg Mn Cr

- Al Mg3

- AW-5754

Exploring the machinability and environmental advantages of 6026 aluminum tubes

Machinability

The 6026 aluminum tube is made from high-efficiency aluminum alloy materials, featuring excellent machinability and cutting performance, making it suitable for high-speed automatic lathes and other machining equipment.

Whether it's extrusion, welding, or anodizing, the 6026 aluminum tube can be processed quickly and accurately, accelerating production cycles, reducing machining costs, and ensuring high quality in the final product.

Environmental Features

The 6026 aluminum tube complies with several European environmental protection directives, such as RoHS and ELV, ensuring it is free from harmful substances and meets modern environmental standards.

Additionally, this alloy can be recycled after use, minimizing environmental impact. By choosing 6026, you not only gain a high-performance product but also demonstrate a commitment to sustainability.

Advantages of 6026 aluminum tubes

- Excellent Mechanical Properties: The 6026 aluminum tube offers high strength, suitable for various load conditions.

- Machinability: This aluminum tube is easy to cut, weld, and anodize, accommodating different processing needs.

- Corrosion Resistance: The 6026 aluminum alloy exhibits outstanding corrosion resistance.

- Environmental Features: It complies with environmental standards such as RoHS and ELV, free from harmful substances and easy to recycle.

- Lightweight and High Strength: Compared to other metal materials, the 6026 aluminum tube is lightweight, making it suitable for weight-reduction designs.

Applications of 6026 aluminum tubes

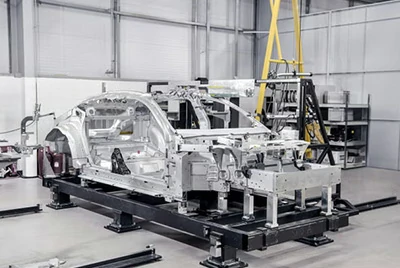

- Automotive Industry: Used in body structural components, radiators, and frames to enhance vehicle lightweighting and safety.

- Construction Industry: Applied in doors, windows, fences, and structural supports.

- Electrical and Electronic Devices: Utilized for enclosures, brackets, and conduits to protect internal components.

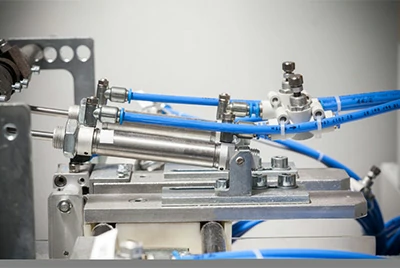

- Mechanical Engineering: Employed in pipelines for hydraulic and pneumatic systems.

- Furniture Design: Used in the structure and decoration of modern furniture.

Quality inspection report — traceable

Our products undergo rigorous quality control, providing a complete set of quality inspection reports.

- Ultrasonic Testing: Ensures no internal defects

- Chemical Composition Analysis: Complies with industry standards

- Mechanical Performance Testing: Validates product strength

- Non-Destructive Testing: Thoroughly identifies potential issues

- Visual Inspection: Striving for perfection

- Traceability Records: Fully traceable throughout the process

Similar products to 6026 aluminum tube

The 6026 aluminum alloy is an excellent alternative to the 6061 and 6082 alloys, particularly suitable for high-volume machining on automatic lathes and machining centers.

The strength of 6026 tubes is comparable to that of 2011 and 2030 alloys, ensuring strength and reliability.