EN AW-6012 aluminum tube is a medium-strength aluminum alloy material with good machinability, corrosion resistance, and suitability for various surface treatments.

It is widely used in lightweight structural components that require high machining precision and durability.

Specifications of 6012 aluminum tube

- EN 573

- EN 755

- EN 754

- ASTM B221

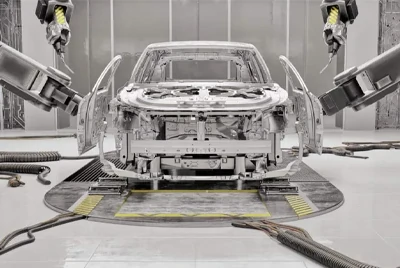

In addition, 6012 aluminum rods comply with the ELV (End-of-Life Vehicles) directive, making them suitable for the automotive industry and ensuring they meet environmental requirements for automotive components.

Popular products and sizes of 6012 aluminum tubes

We offer a variety of specifications and sizes of 6012 aluminum tubes to meet the diverse needs of our customers.

6012 Drawn Aluminum Tube

6012 Drawn Aluminum Tube- High precision and smooth surface, ideal for precision components, with an outer diameter range of 3-100 mm.

6012 Extruded Aluminum Tube

6012 Extruded Aluminum Tube- Moderate strength and low cost, suitable for structural and support parts, with an outer diameter range of 10-300 mm, customizable.

Chemical elements of 6012 aluminum tube

| Chemical Element | % Present |

| Si | 0.60 - 1.40 |

| Fe | 0.50 max |

| Cu | 0.10 max |

| Mn | 0.40 - 1.0 |

| Mg | 0.60 - 1.2 |

| Cr | 0.30 max |

| Zn | 0.30 max |

| Ti | 0.20 max |

| Remarks | 0.70 Bi 0.40 - 2.0 Pb |

| Other (Each) | 0.05 max |

| Others (Total) | 0.15 max |

| Aluminium (Al) | Remainder |

Physical properties of 6012 aluminum tube

| Physical Property | Value |

| Density | 2.90 g/cm³ |

| Melting Point | 640 °C |

| Thermal Expansion | 23 x10^-6 /K |

| Modulus of Elasticity | 69 GPa |

| Shear Modulus | 26 GPa |

| Thermal Conductivity | 160 W/m.K |

| Electrical Resistivity | 45 % IACS |

Mechanical properties of 6012 aluminum tube

Mechanical properties of 6012 extruded aluminum tube - EN 753

| Temper | Wall thickness(mm) | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Hardness (HB) |

| T6, T6510, T6511 | ≤ 30 | Min. 310 | Min. 260 | 8 | 105 |

Mechanical properties of 6012 drawn aluminum tube - EN 754

| Temper | Wall thickness(mm) | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Hardness (HB) |

| T4 | ≤ 20 | Min. 200 | Min. 100 | 10 | - |

| T6 | ≤ 20 | Min. 310 | Min. 260 | 8 | 105 |

Equivalent specifications of 6012 aluminum tube

| EN AW | Al Mg Si Pb |

| Old designation | Al Mg Si Pb |

| Material no. according to DIN | 3.0615 |

| France AFNOR | A-SG0,5 |

| Colour code | RAL 9010 Pure White |

Advantages of 6012 aluminum tube

- Good machinability: Easy to process with high machining efficiency.

- Corrosion resistance: Suitable for humid and corrosive environments, ensuring long service life.

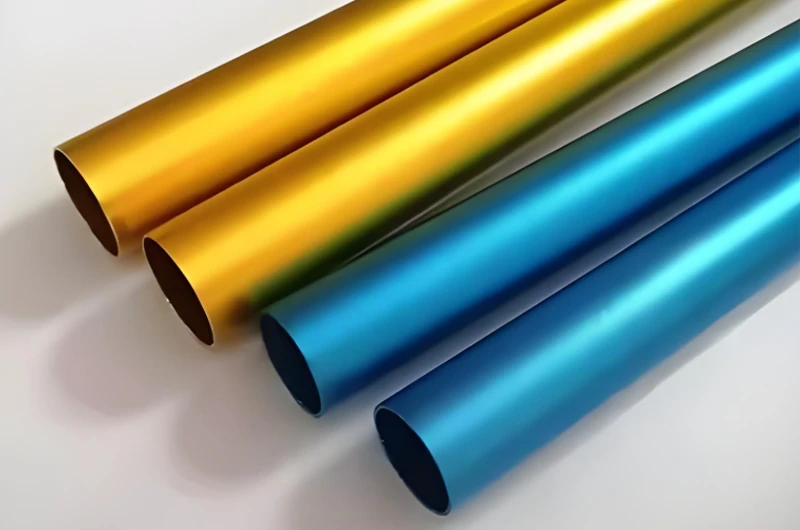

- Good surface treatment: Suitable for anodizing, electroplating, etc., with an aesthetically pleasing appearance.

- Good weldability: Convenient for creating complex structures.

- Environmentally friendly: Produces minimal machining scrap and is recyclable.

Applications of 6012 aluminum tube

- Automotive: Used for lightweight components such as connectors and support rods.

- Electronics and Electrical: Used for connectors, heat exchangers, and other parts.

- Machinery Manufacturing: Suitable for manufacturing fasteners, joints, and other parts.

- Aerospace: Used for small brackets, piping systems, and more.

- Construction and Decoration: Used for architectural decoration parts with good durability and appearance.

Production process of 6012 aluminum tube

Drawn Aluminum Tube: Achieved by cold drawing the tube billet to precise dimensions, with a smooth surface, suitable for precision components. Annealing is typically required to restore toughness.

Extruded Aluminum Tube: After heating the ingot, the tube is directly extruded, ideal for large diameter, thick-walled tubes. Fast production speed makes it suitable for structural and support components.

Anodizing of 6012 aluminum tube

Anodizing treatment enhances the corrosion resistance, wear resistance, surface hardness, and improves appearance. It is suitable for automotive, construction, and electronic applications.

Brazing process of 6012 aluminum tube

The brazing process for 6012 aluminum tube includes surface cleaning, selecting aluminum brazing filler, heating until the filler melts, and cooling to solidify. This process is widely used for heat exchangers and automotive component connections.

Comparison with other easily machinable lead alloys

- Machinability: 6012 aluminum alloy offers good machinability, comparable to other free-machining alloys like 6020 and 6262, but contains little to no lead, reducing environmental concerns.

- Environmental Impact: 6012 aluminum alloy has lower lead content than high-lead alloys like 2011, making it more environmentally friendly and suitable for applications with high environmental standards.

Does Mastar offer customization services?

Yes, we offer customization services for 6012 aluminum tubes to meet the specific needs of your projects.

Whether it's size specifications, shapes (round tubes, square tubes, rectangular tubes), or special surface treatments (such as anodizing or electroplating), we can tailor the products to your requirements.

Our experienced team ensures that each product meets strict quality standards, providing you with high-precision, high-quality aluminum tube solutions.

Quality inspection report – traceable

Our products undergo rigorous quality control, and we provide a full set of quality inspection reports:

- Ultrasonic Testing: Ensures there are no internal defects.

- Chemical Composition Analysis: Complies with industry standards.

- Mechanical Performance Testing: Verifies product strength.

- Non-Destructive Testing: Comprehensive hazard inspection.

- Appearance Inspection: Ensures fine-tuned quality.

- Traceability Records: Fully traceable throughout the process.

Contact us for more information

If you are looking for aluminum alloy materials with excellent machinability and outstanding corrosion resistance, 6012 aluminum tube is undoubtedly your best choice.

Feel free to contact us anytime for more information and quotes regarding 6012 aluminum alloy.