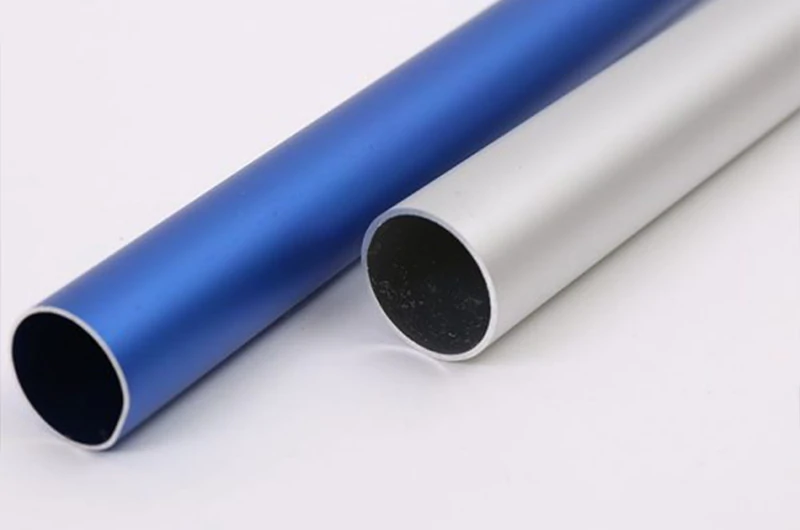

6011 aluminum tube belongs to the 6 series aluminum alloy tube, which has high strength and corrosion resistance and is widely used in various application scenarios. This alloy tube is produced through precision extrusion and drawing processes, and the mechanical properties of the finished tube are excellent, suitable for a variety of industrial uses.

Hot selling size table of 6011 aluminum tube

The following table shows the sizes that our customers frequently order, with a variety of specifications available. The table lists a wide range of sizes, covering different configurations with outer diameters from 10 to 350 mm and wall thicknesses from 1 to 30 mm, usually in lengths of 6000 mm each.

| Product | OD (mm) | Wall Thickness (mm) | Length (mm) |

| 6011 aluminum tube | 10 | 1 | 6000 |

| 6014 aluminum tube | 50 | 4 | 6000 |

| 6016 aluminum tube | 90 | 6 | 6000 |

| 6020 aluminum tube | 180 | 14 | 6000 |

| 6022 aluminum tube | 220 | 18 | 6000 |

| 6023 aluminum tube | 250 | 20 | 6000 |

| 6024 aluminum tube | 280 | 22 | 6000 |

| 6025 aluminum tube | 300 | 25 | 6000 |

| 6026 aluminum tube | 350 | 30 | 6000 |

Chemical composition of 6011 aluminum tube

| Element | Composition % |

| Al | Remainder |

| Si | 0.6-1.2 |

| Fe | 0.7-1 |

| Cu | ≤0.1 |

| Mn | 0.2-0.5 |

| Mg | 0.80-1.30 |

| Cr | ≤0.1 |

| Sn | ≤0.05 |

| Ti | ≤0.1 |

| Sb | ≤0.05 |

| Zr | ≤0.05 |

| B | ≤0.05 |

Characteristics of 6011 aluminum tube

The main components of 6011 aluminum tube are aluminum and silicon, and also contain a small amount of alloy elements such as copper and magnesium. This material has the following characteristics:

Good corrosion resistance: The silicon content in 6011 aluminum tube improves its corrosion resistance, making it suitable for harsh environments such as moisture and chemical contact.

Medium strength: Compared with other 6 series aluminum alloys, 6011 aluminum tube has medium strength, suitable for applications that require certain strength but not high strength.

Good machinability: This aluminum alloy tube is easy to process and can be bent, cut and welded, suitable for manufacturing products with complex shapes.

Excellent surface treatment performance: 6011 aluminum tube performs well when subjected to surface treatments such as anodizing and electrophoretic coating, which can enhance its durability and aesthetics.

Application fields of 6011 aluminum tube

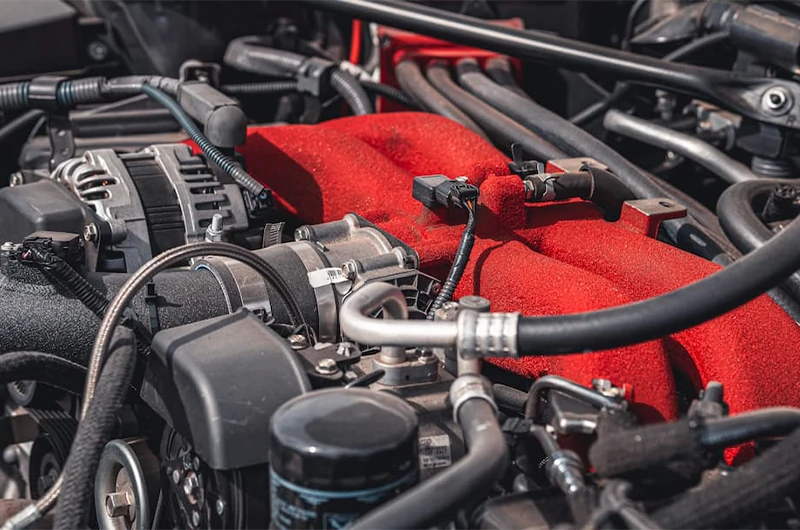

Automotive industry: Due to the light weight and medium strength of 6011 aluminum tube, it is used to manufacture automobile cooling system pipes, oil pipes and structural components, which can effectively reduce the weight of the whole vehicle and improve fuel efficiency.

Building structure: In the construction industry, 6011 aluminum tube can be used to manufacture lightweight structural parts such as handrails, door and window frames, which are corrosion-resistant and plastic.

Home appliance manufacturing: such as the heat dissipation components of refrigerators and air conditioners, using the good thermal conductivity and corrosion resistance of 6011 aluminum tube to extend the service life of the product.

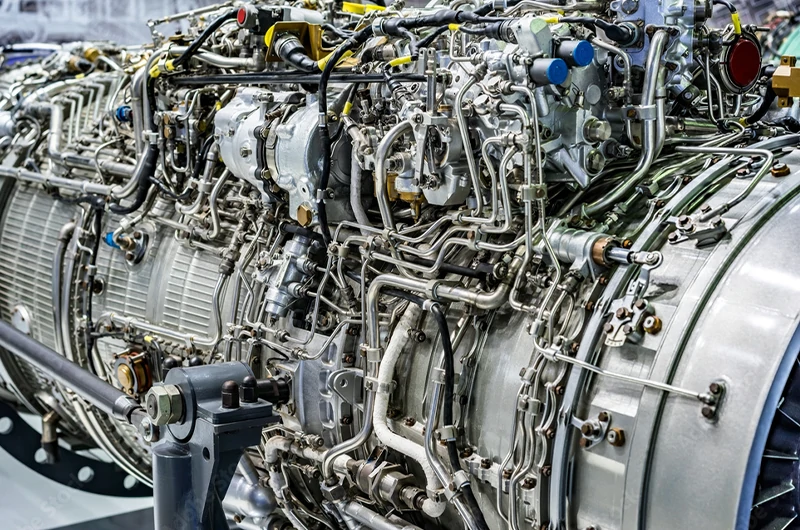

Aerospace: 6011 aluminum tube can be used in some light-load structures such as aviation pipelines and brackets due to its moderate strength and weight ratio.

Production process of 6011 aluminum tube

6011 aluminum tubes are usually produced by extrusion molding process, and can also be further refined by drawing or rolling process to meet the requirements of different sizes and precision.

Extrusion process: The 6011 aluminum alloy raw material is heated to a suitable temperature and extruded through a die to form the aluminum into a tube.

Drawing process: The extruded tube can be further adjusted by drawing to adjust the wall thickness and outer diameter, and improve the surface finish and precision.

Heat treatment: Appropriate annealing and solution treatment of 6011 aluminum tubes can improve its internal structure and performance.

Advantages and limitations of 6011 aluminum tube

Advantages of 6011 aluminum tube

Good corrosion resistance: The silicon content in 6011 aluminum tube makes it highly corrosion-resistant and suitable for use in humid, marine climates and chemical environments.

Excellent processability: 6011 aluminum tube can be processed by bending, cutting, welding and other processing methods, suitable for manufacturing components with complex structures, and can be subjected to various surface treatments such as anodizing and electrophoresis to further enhance its durability and aesthetics.

Moderate strength-to-weight ratio: 6011 aluminum tube has moderate strength and light weight, which can reduce the overall weight while maintaining structural strength, and is suitable for applications with weight requirements, such as automobile and home appliance manufacturing.

High cost-effectiveness: Compared with some higher strength or higher performance aluminum alloys, 6011 aluminum tube has a lower cost, making it an ideal choice for large-volume applications with economical advantages.

Limitations of 6011 aluminum tube

Lower strength: Compared with 7-series and 2-series high-strength aluminum alloys, 6011 aluminum tubes have lower strength and are therefore not suitable for applications with high load and high strength requirements, such as aerospace structures and high-pressure vessels.

Limited heat treatment strengthening: The heat treatment strengthening effect of 6011 aluminum alloy is not as good as some high-performance alloys, and the strength improvement space is limited. Therefore, it is not as suitable as other heat-treatable aluminum alloys in some occasions where heat treatment toughening is required.

Limited high temperature resistance: The performance of 6011 aluminum tubes decreases rapidly under high temperature conditions and cannot be exposed to high temperature environments for a long time. In environments with extreme temperature changes, its mechanical properties and stability may be affected.

Low welding strength: Although 6011 aluminum alloy has good weldability, the strength of the welded area after welding is usually lower than that of the parent material, so it may not be as ideal as other specific weldable alloys in some applications requiring high welding strength.

Mastar's 6011 Aluminum Tube Purchasing Guide

Before buying 6011 Aluminum Tube from Mastar, please confirm the size and quantity you need. Then, contact our customer service team and we will provide you with the best quality products and the most competitive market prices.

6011 aluminum tube price

6011 aluminum tube price: (LME ingot price + processing fee) × weight + packaging fee + transportation fee

Please contact Mastar to inquire about the price and the processing fee per ton of aluminum tubes of various specifications. The processing fee of 6011 aluminum tubes of different sizes may vary greatly, and we will provide you with the best quotation.

Surface treatment

In order to improve the durability of 6011 aluminum tubes, they are usually subjected to a variety of surface treatments, including:

Anodizing: Forming an aluminum oxide layer to improve its corrosion resistance and wear resistance and increase decorativeness.

Electrophoretic coating: Coating a protective film on the surface of the tube to increase its anti-oxidation and anti-pollution capabilities.

Powder coating: It can achieve rich color and texture effects while further enhancing the surface hardness.

6011 aluminum tube quality inspection standard

In order to ensure the quality of 6011 aluminum tubes, manufacturers usually perform the following quality tests:

- Tensile test: evaluate the tensile strength, ductility and other properties of the tube.

- Hardness test: measure the hardness of the tube to determine its applicability.

- Corrosion resistance test: evaluate its corrosion resistance through salt spray test, immersion test, etc.

- Surface inspection: check its surface finish to ensure there are no defects such as cracks and pores.

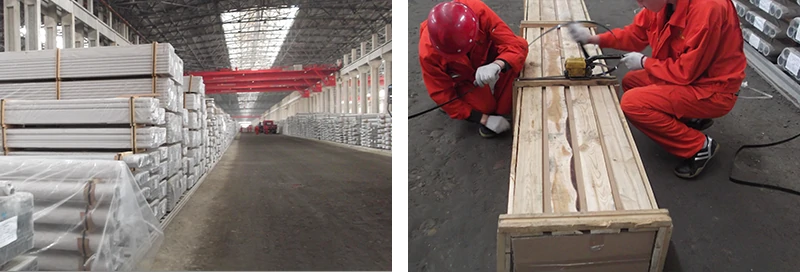

6011 aluminum tube packaging

Plastic or kraft paper packaging with moisture-proof desiccant inside.

Mounted on wooden pallets, reinforced with steel straps, and provided with fumigation certificate.

Complies with GB/T3199 standard requirements.

Packaging can be customized according to other customer requirements.