5251 aluminum tubes are medium-strength, easy-to-weld, and formable alloy products with excellent corrosion resistance, particularly suitable for marine environments.

Their primary alloying elements are magnesium and manganese, providing outstanding oxidation resistance and cold working properties.

5251 NS4 aluminum tube specifications

- BS L56

- BS L100

- EN 573

- EN 755

- EN 754

- BS 5L44

- BS 3L56

Stock sizes of 5251 NS4 aluminum tubes

5251 aluminum tubes are available in various diameters and wall thicknesses to meet the diverse engineering needs of customers.Quick Quote

- Standard lengths: 3 meters or 6 meters (custom lengths available)

- Common tempers: O, H22, H24, H26, H28

- Surface treatment: Anodizing

5251 aluminum round tubes - Diameter range: 6 mm - 200 mm

- Wall thickness range: 0.5 mm - 10 mm

Contact us now 5251 aluminum square tubes - Side length range: 10 mm - 150 mm

- Wall thickness: 1 mm - 10 mm

Contact us now 5251 aluminum rectangular tubes - DWidth range: 10 mm - 150 mm

- Height range: 20 mm - 200 mm

- Wall thickness: 1 mm - 10 mm

Contact us now

Chemical elements of 5251 NS4 aluminum tube

| Chemical Element | % Present |

| Si | 0.0 - 0.40 |

| Fe | 0.0 - 0.50 |

| Cu | 0.0 - 0.15 |

| Mn | 0.10 - 0.50 |

| Mg | 1.70 - 2.40 |

| Cr | 0.0 - 0.15 |

| Zn | 0.0 - 0.15 |

| Ti | 0.0 - 0.15 |

| Other (Each) | 0.05 max |

| Others (Total) | 0.15 max |

| Aluminium (Al) | Balance |

Physical properties of 5251 NS4 aluminum tube

| Physical Property | Value |

| Density | 2.70 g/cm³ |

| Melting Point | 650 °C |

| Thermal Expansion | 23.4 x10^-6 /K |

| Modulus of Elasticity | 68 GPa |

| Shear Modulus | 26 GPa |

| Thermal Conductivity | 150 W/m.K |

| Electrical Resistivity | 37 % IACS |

Mechanical properties of 5251 NS4 aluminum tube

| Temper | Wall thickness (mm) | Tensile strength (MPa) | Yield strength (MPa) | Elongation (%) | Hardness (HB) |

| O, H111 | ≤ 20 | Min. 150 Max. 200 | Min. 60 | 17 | 45 |

| H12, H22, H32 | ≤ 10 | Min. 180 Max. 220 | Min. 110 | 5 | 60 |

| H14, H24, H34 | ≤ 5 | Min. 200 Max. 240 | Min. 180 | 4 | 65 |

| H16, H26, H36 | ≤ 5 | Min. 220 Max. 260 | Min. 180 | 3 | 70 |

| H18, H28, H38 | ≤ 3 | Min. 240 | Min. 200 | 2 | 80 |

Advantages of 5251 NS4 aluminum tubes

- Corrosion Resistance: 5251 aluminum tubes are particularly suitable for marine environments, maintaining good corrosion resistance in humid and salt-spray conditions.

- Formability: 5251 aluminum tubes exhibit excellent formability during cold processing, making them suitable for various structural bending and forming operations.

- Lightweight: 5251 aluminum tubes are ideal for applications that require weight reduction, such as in the marine and automotive sectors.

- Weldability: 5251 aluminum tubes can be easily welded, making them suitable for engineering applications that require assembly in pipeline systems and frame structures.

- Aesthetic Appeal: 5251 aluminum tubes can be easily anodized, enhancing surface aesthetics.

Applications of 5251 NS4 aluminum tubes

- 5251 aluminum tubes are suitable for use in ship structures, marine, and offshore platforms that are exposed to seawater for extended periods.

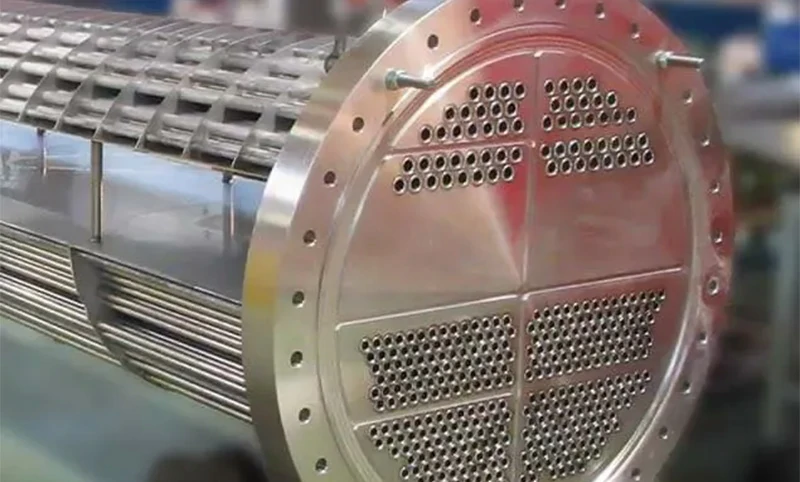

- Due to their good thermal conductivity and corrosion resistance, 5251 aluminum tubes are commonly used in heat exchange devices such as boilers and heat exchangers.

- 5251 aluminum tubes are widely used in the manufacture of pressure vessels, especially in fuel tanks and fluid containers.

- 5251 aluminum tubes can be used for stamping parts, particularly in construction and engineering applications that require weather resistance.

- 5251 aluminum tubes are an ideal choice for lightweight structures such as automotive and home plumbing systems.

- 5251 aluminum tubes are commonly used in irrigation systems, road signs, containers, and other projects.

Processing recommendations for 5251 NS4 aluminum tubes

- The workability of 5251 aluminum is better than that of pure aluminum, making it suitable for various manufacturing processes.

- It is recommended to use sharp cutting tools and maintain a high machining speed.

- Keeping cutting tools sharp and using appropriate cutting angles can improve machining precision and efficiency.

- Ensure the use of sufficient lubricants during processing, which can help enhance cutting quality.

- 5251 aluminum, particularly in the H22 temper, exhibits good cold-forming properties.

- Whether bending, drilling, or cutting, 5251 aluminum delivers excellent results.

Welding recommendations for 5251 NS4 aluminum tubes

- 5251 aluminum is suitable for various welding methods, especially Gas Metal Arc Welding (MIG) and Tungsten Inert Gas Welding (TIG).

- When welding with 5251, 6XXX, or 7XXX series alloys, it is recommended to use 5356 filler wire.

- When welding with 5005, 5020, 1XXX, or 3XXX series alloys, it is recommended to use 4043 filler wire.

- The brazability of 5251 aluminum alloy is poor, and brazing processes are not recommended.

Equivalent specifications for 5251 NS4 aluminum tubes

| EU EN | ENAW-AlMg2(B) |

| USA | A95052 |

| Germany DIN/WNr | 3.3326 AlMg1.8 AlMg2.5 |

| Japan JIS | 5052 |

| France AFNOR | 5052 |

| England BS | 5251 |

| Italy UNI | P-AlMg2.5 |

| Sweden SS | AlMg2.5 |

| Poland PN | AlMg2 |

| Czechia CSN | 424412 |

| Austria ONORM | AlMg2.5 |

| Inter ISO | AlMg2 |

Similar products to 5251 NS4 aluminum tubes

5052 Aluminum Tubes - 5052 can serve as a substitute for 5251, as both have similar chemical compositions and mechanical properties.

Contact us now 5005 Aluminum Alloy - The strength of 5005 is lower than that of 5251, making it unsuitable for applications that require higher strength.

Contact us now 5083 Aluminum Alloy - 5083 has a higher strength than 5251, making it suitable for applications that require greater structural strength.

Contact us now

5251 aluminum round tubes

5251 aluminum round tubes 5251 aluminum square tubes

5251 aluminum square tubes 5251 aluminum rectangular tubes

5251 aluminum rectangular tubes 5052 Aluminum Tubes

5052 Aluminum Tubes 5005 Aluminum Alloy

5005 Aluminum Alloy 5083 Aluminum Alloy

5083 Aluminum Alloy