3004 Aluminum Welded Tube is a high-performance, high-frequency welded tube made by forming aluminum flat strips and then connecting the edges through a high-frequency welding process. Compared to extruded and drawn tubes, the main distinction of welded tubes is that they can utilize multiple layers of different aluminum alloys. Composite layers are widely used in the production of heat exchanger piping for in-furnace or flame brazing, providing sacrificial corrosion resistance.

3004 is renowned for its medium strength and excellent corrosion resistance. It primarily consists of aluminum, manganese, and magnesium, with about 1% magnesium added to enhance its performance over traditional 3003 alloy. 3004 aluminum alloy can achieve increased strength through cold working while maintaining good machinability and enhancing its tensile strength.

Click to view the 3004 Aluminum Welded Tube Product Guide

Popular products of 3004 aluminum welded tubes

3004 weld aluminum pipe

3004 weld aluminum pipe- Temper: O,H32,H34,H36,H38

- Spec: ASTM B313

3004 Round HF Aluminum Welded Tubes

3004 Round HF Aluminum Welded Tubes- Spec: EN 1592, EN 573

- Composite Layer: 7072

- Applications: Evaporators, condensers, connecting pipes

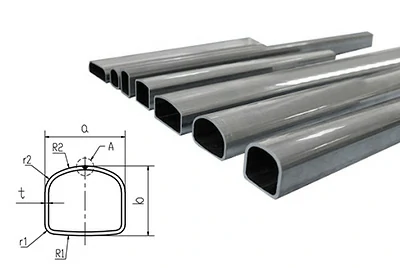

3004 D-type HF Aluminum Welded Tubes

3004 D-type HF Aluminum Welded Tubes- Spec: EN 1592, EN 573

- Composite Layer: 7072

- Applications: Automotive air conditioning system condensers, evaporators, heat exchangers

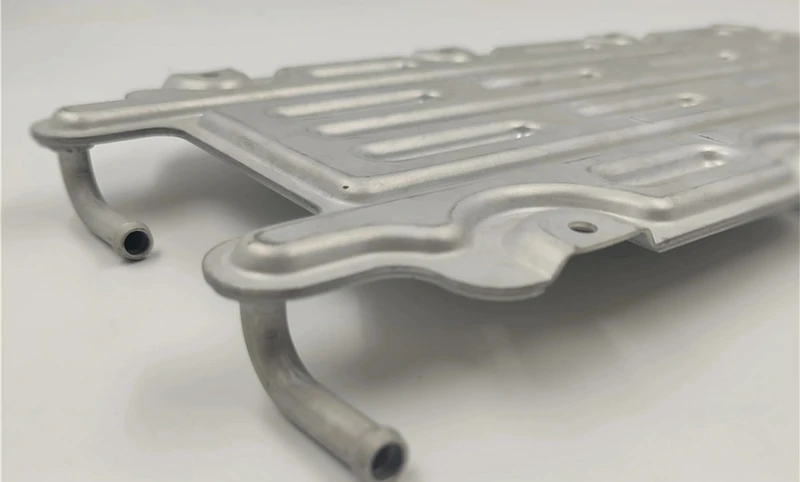

3004 HF welded aluminum radiator tube

3004 HF welded aluminum radiator tube- Spec: EN 1592, EN 573

- Composite Layer: 4343, 4045

- Applications: Automotive radiators, condensers

Features of 3004 aluminum welded tubes

- High Strength: Higher strength than 3003, suitable for occasions where structural integrity is required.

- Corrosion Resistance: Excellent corrosion resistance in humid and chemical environments.

- Weldability: Good welding performance, suitable for various industrial welding.

Best applications for 3004 aluminum welded tubes

Industrial Equipment - In the field of industrial equipment, 3004 aluminum tube is often used to manufacture pipes for transporting liquids and gases, especially in applications that require lightweight and corrosion resistance.

Pipes and Pressure Vessels - In the chemical and petroleum industries, 3003 aluminum tube is used to manufacture low-pressure containers and piping systems. Its corrosion resistance and strength can withstand medium-pressure environments, making it a safe choice for transporting chemicals.

Roof Drainage Systems - The corrosion resistance of 3004 aluminum tube makes it perform well in roof drainage systems. 3003 aluminum tube is often used in building components such as drainage pipes and gutters to ensure long-term stability and low maintenance costs.

Coolers and Radiators - The thermal conductivity of 3004 makes it an ideal choice for manufacturing coolers and radiators. In automobiles, electronic equipment, and home appliances, 3003 aluminum tube is widely used in heat transfer components to improve heat dissipation efficiency.

3004 Aluminum welded tubes procurement guide

1.Comprehensive documentation

Msatar can provide detailed quality testing reports, including raw material certificates, laboratory test reports, fumigation reports, specification guides, commercial invoices, and guarantees, ensuring the quality transparency and traceability of each batch of products.

2.Fine export packaging

In international shipping, the quality of packaging directly affects whether goods can rust, corrode, scratch, deform, or suffer other damages during transport. Therefore, high-quality packaging materials are crucial. Msatar has years of export packaging experience, providing safe and reliable packaging solutions for thousands of businesses. By using fumigated wooden boxes, wooden pallets, and other high-quality packaging materials, our packaging damage rate is only one-third of the industry average.

3.Professional loading solutions

Our experienced order-following team can provide flexible and diverse loading solutions, including options for 20/40-foot containers or bulk ships. Regardless of your cargo specifications and shapes, we can customize a refined loading plan that saves an average of 15% container space, effectively reducing your logistics costs.

UNS A93004 aluminum welded tube knowledge center

Equivalent Name of 3004 aluminum alloy

- ENAW-AlMn1Mg1

- 3.0526

- AlMn1Mg1

- D12

- A-M1G

- AlMn1Mg1

Specification for 3004 aluminum tube

- EN 1592-2: 1998 - Aluminium and aluminium alloys. HF seam welded tubes. Mechanical properties

- ASTM B313 - Standard Specification for Aluminum and Aluminum-Alloy Round Welded Tubes

- EN 573-3: 2009 Aluminium and aluminium alloys. Chemical composition and form of wrought products. Chemical composition and form of products

Chemical composition of 3004 aluminum tube

| Element | UNS A93004 |

| Si | 0.30 |

| Fe | 0.7 |

| Cu | 0.25 |

| Mn | 1.0-1.5 |

| Mg | 0.8-1.3 |

| Cr | - |

| Zn | 0.25 |

| Ti | - |

| Others (Each) | 0.05 |

| Others (Total) | 0.15 |

| Al | Rem |

Physical properties of 3004 aluminum tube

| Properties | 3004 |

| Density | 2.72 g/cm³ |

| Melting point | 562-646°C |

| Thermal conductivity | 148 W/m·K |

| Coefficient of thermal expansion | 23.8 µm/m·°C |

| Electrical conductivity | 40 % IACS |

Mechanical properties of 3004 aluminum tube

| Properties | O | H32 | H34 | H36 | T38 |

| Tensile strength Rm/Ksi | 22-29 | 28-35 | 32-38 | 35-41 | 38 |

| Yield strength Rp0.2/Ksi | 8.5 | 21 | 25 | 28 | 31 |

| Elongation | 16-18% | 4-6% | 3-5% | 3-4% | 3-4% |

3003 vs 3004

3003 is a general-purpose aluminum alloy composed mainly of aluminum and manganese. It has medium strength, good formability and excellent corrosion resistance. This alloy can be cold worked but not heat treated and is commonly used in the manufacture of various types of containers and decorative products.

3004 aluminum alloy is based on 3003 alloy and adds about 1% magnesium, thereby significantly improving the strength of the material. It also has good formability and corrosion resistance, but its mechanical properties are superior.

Strength and Hardness

- 3003: Suitable for medium-strength applications. It has low tensile strength and yield strength, but good ductility, suitable for deep drawing and stretching.

- 3004: Stronger than 3003, suitable for applications requiring higher strength, such as beverage can manufacturing and structural parts. Can withstand greater mechanical stress and strain.

Formability

- 3003: Excellent formability, suitable for forming processes requiring complex shapes.

- 3004: Good deep drawing forming ability, can process thinner blanks, especially suitable for manufacturing containers with complex shapes.

Corrosion resistance

- 3003: Good corrosion resistance, stable in most environments.

- 3004: Due to the addition of magnesium, the corrosion resistance is further enhanced, suitable for use in humid and corrosive environments.

Weldability

- 3003: Good weldability, suitable for conventional welding operations.

- 3004: Better weldability than 3003, especially suitable for MIG and TIG welding.

Both 3003 and 3004 aluminum alloys are cost-effective materials commonly used in construction, packaging and industrial manufacturing. 3003 aluminum alloy is suitable for general applications due to its formability and corrosion resistance, while 3004 aluminum alloy is ideal for complex and high-strength occasions due to its higher strength and good corrosion resistance.