2030 alloy is one of the aluminum-copper alloy series. It has high strength and excellent mechanical properties and is widely used in aerospace, military industry and other fields with high strength requirements.

MASTAR 2030 aluminum tube product introduction

Stock product types: Drawn tube, Extruded tube, Extruded profiles

Length: Can be cut to any length.

Aluminum tube ends: bending, welding, punching, laser cutting, threading, turning

Surface treatment: mill finish, anodizing, grinding, polishing, powder coating, etc.

Equivalent names: ALUMINIUM AW-2030; AlCu4PbMg; AW-AlCu4PbMg; AlCuMgPb; 3.1645

| Europe | USA | Spain | France | Germany | GB | Italy | Sweden | Switzerland | Japan |

| EN 573 | AA | UNE | AFNOR | DIN | BS | UNI | SIS | VSM | JIS |

| EN A W 2030 | 2030 | 38.319 L-3121 | A-U4Pb | 3.1645 AICuMgPb | 7L25 | 4335 | AICu4MgPb |

MASTAR 2030 drawn tube

- Processed through the cold drawing process, 2030 aluminum alloy drawn tubes have high precision, good surface finish, and significant strength improvement, and are suitable for applications with precision structures and high strength requirements.

Processed through the cold drawing process, 2030 aluminum alloy drawn tubes have high precision, good surface finish, and significant strength improvement, and are suitable for applications with precision structures and high strength requirements.

Features of 2030 drawn tube:

- High strength: 2030 alloy has a high copper content and excellent tensile strength, making it suitable for the manufacture of high-strength structural parts.

- Good dimensional accuracy: The drawing process can produce very high-precision tubes, suitable for applications with strict dimensional requirements.

- Excellent surface quality: The surface of the drawn 2030 alloy tube is relatively smooth, which reduces the cost of surface treatment in subsequent processing.

2030 drawn tube application:

- Precision mechanical parts

- Tubes with high dimensional accuracy requirements in aerospace and military equipment

| 2030 drawn tube mechanical properties | |||||||

| Temper | Measurements mm | R m MPa | R p0.2 MPa | A% | A 50 mm % | ||

| min. | max. | min. | max. | min | min. | ||

| T3 | ≤20 | 370 | - | 240 | - | 7 | 5 |

| T3510 T3511 | ≤20 | 370 | - | 240 | - | 5 | 3 |

MASTAR 2030 aluminum extruded tube

- The 2030 aluminum alloy extruded tube produced by the extrusion process has excellent strength, fatigue resistance and dimensional flexibility, and is suitable for high-stress, large-size structural parts.

2030 aluminum extruded tube features:

- High strength and fatigue resistance: Extruded tubes have good mechanical properties and are suitable for structural parts subject to greater stress.

- Dimensional flexibility: The extrusion process can produce pipes of various sizes and shapes to meet different engineering needs.

- Good Processability: 2030 extruded tube has good processability and is suitable for further machining or welding.

2030 aluminum extruded tube applications:

- High strength structural parts

- Large-dimension piping systems in industry and construction

2030 extruded tube mechanical properties

| 2030 extruded tube mechanical properties | |||||||

| Temper | Measurements mm | R m MPa | R p0.2 MPa | A% | A 50 mm % | ||

| min. | max. | min. | max. | min | min. | ||

| T4 T4510 T4511 | ≤25 | 370 | - | 250 | - | 8 | 6 |

MASTAR 2030 extrusion profiles

- The complex cross-section profiles formed by extrusion of 2030 aluminum alloy have the advantages of high strength, impact resistance and complex shape design, and are widely used in structures with high bearing capacity requirements.

2030 extrusion profile features:

- Complex shapes: Through the extrusion process, profiles with various complex cross-sections can be produced, which are suitable for projects with diverse structural design requirements.

- High strength and impact resistance: The high strength of 2030 alloy itself enables it to withstand greater stress and is widely used in structures with high bearing capacity requirements.

- Good wear resistance and corrosion resistance: After heat treatment, 2030 profile has good corrosion resistance in certain environments.

2030 extrusion profile application:

- As high-strength support parts in aerospace and military industries

- Skeleton materials in building and industrial machinery structures

| 2030 Extrusion Profile Mechanical Properties | |||||||

| Temper | Measurements mm | R m MPa | R p0.2 MPa | A% | A 50 mm % | ||

| min. | max. | min. | max. | min | min. | ||

| T4 T4510 T4511 | ≤30 | 370 | - | 280 | - | 8 | 6 |

MASTAR 2030 aluminum tube supply shapes

- 2030 Aluminum Round Tube

- 2030 Aluminum Square Tube

- 2030 Aluminum Flat Tube

- 2030 Aluminum Rectangular Tube

- 2030 Aluminum Hexagonal Tube

- 2030 other custom section pipe

2030 aluminum tube chemical composition

| 2030 aluminum tube chemical composition | |

| Aluminum (Al) | 88.9 to 95.2 |

| Copper (Cu) | 3.3 to 4.5 |

| Lead (Pb) | 0.8 to 1.5 |

| Magnesium (Mg) | 0.5 to 1.3 |

| Manganese (Mn) | 0.2 to 1.0 |

| Silicon (Si) | 0 to 0.8 |

| Iron (Fe) | 0 to 0.7 |

| Zinc (Zn) | 0 to 0.5 |

| Titanium (Ti) | 0 to 0.2 |

| Bismuth (Bi) | 0 to 0.2 |

| Chromium (Cr) | 0 to 0.1 |

| Residuals | 0 to 0.3 |

MASTAR 2030 aluminum tube performance

MASTAR 2030 aluminum tube is a high-strength aluminum-copper alloy with the following performance characteristics:

- High strength: 2030 aluminum alloy contains a high copper content and has excellent tensile strength and yield strength, making it very suitable for applications that withstand high stress.

- Good machinability: This aluminum alloy has good machinability and formability, suitable for precision machining and manufacturing of complex shapes.

- Moderate corrosion resistance: 2030 aluminum alloy has some corrosion resistance after proper surface treatment, but due to the high copper content, the corrosion resistance is not as good as other low copper content aluminum alloys.

- Good weldability: It can be processed by conventional welding methods, but appropriate heat treatment process is required after welding to ensure the strength of the weld area.

- Good fatigue resistance: It has good fatigue resistance under high-strength conditions and is suitable for load-bearing structures used for a long time.

MASTAR 2030 aluminum tube cooperation areas

Due to its high strength and processability, MASTAR 2030 aluminum tube is suitable for use in many demanding fields, including:

- Aerospace: Due to its high strength and good fatigue resistance, 2030 aluminum tube is widely used in aviation structural parts and support components, suitable for key components such as aircraft body, wings, brackets, etc.

- Military equipment: In the military field, the excellent mechanical properties of 2030 aluminum alloy make it an ideal material for missile casings, ammunition casings and other military equipment.

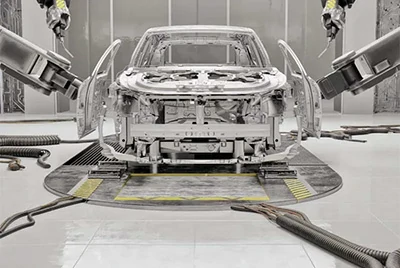

- Automobile Manufacturing: Its high strength and weight reduction effect make 2030 aluminum tubes used in the structural parts of high-performance automobiles, especially in important parts such as the chassis and frame of racing cars and commercial vehicles.

- Precision Machinery: 2030 aluminum tube is suitable for manufacturing complex precision machinery parts, such as housings and support frames of instruments and electronic equipment, due to its good cutting and processing properties.

- Architecture and Structure: In building structures that require high-strength bearing, 2030 aluminum tubes can also be used as frames and supporting components, especially in high-performance building materials and bridge construction.

Why MASTAR becomes the preferred supplier of aluminum 2030 tubes

- Fast Delivery: We have abundant inventory to ensure fast shipment of any product, saving time for your project.

- Customized service: MASTAR can provide customized service according to customer needs. You only need to inform the length, quantity, surface finish, cutting, bending, color coating, end use and other special requirements.

- Competitive Price: Our products are priced competitively and we offer reasonable discounts for large quantities, giving you better prices and quality service.

- After-sales support: We provide fast after-sales support to ensure that you get timely help and support when using our products.