7A04 aluminum bar is an ultra-high-strength aluminum alloy belonging to the Al-Zn-Mg-Cu system. It has significantly high strength, good corrosion resistance and excellent processing performance. This aluminum alloy is widely used in fields such as aerospace, automotive and defense industries that require high strength and durability. Its advantage lies in maintaining stable mechanical properties in high-stress environments while providing a lightweight solution.

Click to view 7a04 Aluminum Rod Product Guide

Msatar offers a variety of product lines of 7A04 aluminum rods, including a variety of different diameters and lengths to meet the needs of different industrial fields. Specific specifications and size ranges are as follows:

- 7a04 extrusion aluminum bar

- Temper: O,T6,T6511,T73,T73511,T76,T76511

- DIA: 0.4"-16"(10-420mm)

- 7a04 cold finished aluminum bar

- Temper: O,T6,T651,T73,T7351

- DIA: 0.2"-8"(5-200mm)

- 7a04 aluminum cast billets bar

- Temper: F

- DIA: 4.8"-53"(124-1350mm)

- Material used for subsequent extrusion production

- 7a04 aluminum forged bar

- Temper: T6,T652,T73,T7352

- DIA: 7.8"-40"(200-1000mm)

- Made by forging process, it has extremely high strength, fatigue resistance and high temperature resistance.

Popular products of 7A04 aluminum bar

- 7a04 O extrusion aluminum bar

- 7a04 T6/T6511 extrusion aluminum bar

- 7a04 T73/T73511 extrusion aluminum bar

- 7a04 T76/T76511 extrusion aluminum bar

- 7a04 T652 aluminum forged bar

- 7a04 T7352 aluminum forged bar

- 7a04 aluminum round bar

- 7a04 aluminum square bar

- 7a04 aluminum flat bar

- 7a04 large diameter aluminum bar

- 7a04 cold finished aluminum wire

- 7a04 aluminum wire rod for rivets

What we provide as a high-quality aluminum bar supplier

- Premium Products: Using high-quality aluminum billets and precise alloying and heat treatment processes, we optimize strength and ductility, ensuring uniform cooling and annealing. This guarantees high tensile strength and excellent performance.

- Grain Control: Produced through reverse extrusion, our aluminum bars have controlled cooling rates and homogenization treatment, maintaining grain size at ≤0.5mm to minimize quality defects, enhance material consistency, and refine microstructure.

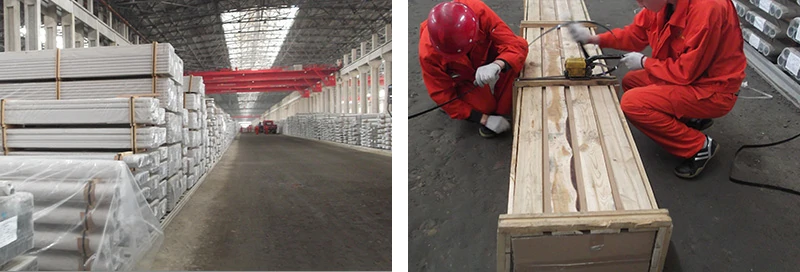

- Timely Delivery: With a 10,000-ton inventory, standard sizes are ready for immediate dispatch. Advanced equipment and a skilled team ensure fast production cycles and reliable logistics for on-time delivery.

- Competitive Pricing: We support both retail and bulk procurement for metal distributors, offering discounts and rebate policies for B2B customers. Transparent pricing ensures our aluminum bar quality comes at a price advantage.

- Comprehensive Quality Testing: We implement strict multi-step testing, including tensile strength, elongation, ultrasonic testing, and metallographic inspection, ensuring that our aluminum bars meet AMS, EN, and NADCAP standards.

- Customer Service: We provide complete after-sales support, addressing customer concerns with an experienced technical team offering professional advice and guidance, and an established customer service system to guarantee an exceptional service experience.

Features of 7A04 aluminum bar

- High strength (tensile strength can reach 530 MPa), good heat treatment strengthening effect, medium plasticity in annealing and new quenching state;

- Unlike hard aluminum, the corrosion resistance in artificial aging state is better than that in natural aging state, and the natural aging process is slow, and it takes 3 months to reach the aging hardening peak, so 7A04 is used in the quenching artificial aging state;

- Its disadvantages are low organizational stability, low low-frequency fatigue strength, and a tendency to stress corrosion cracking;

- The alloy has good spot welding weldability, poor gas welding, good machinability after heat treatment, but poor machinability after annealing.

Best cooperation fields for 7A04 aluminum bar

Aerospace field: 7A04 aluminum bar is widely used in aircraft structural parts due to its excellent strength and corrosion resistance, such as beam trusses, bulkheads, wing ribs, landing gear, engine brackets and other load-bearing parts as well as bolts, screws and other connecting parts.

Defense industry: 7A04 aluminum bar is widely used in the defense industry to manufacture high-strength, corrosion-resistant armor parts and structural brackets. Its ultra-high strength ensures the stability and reliability of the material in extreme environments.

7A04 aluminum bar procurement guide

1.Comprehensive documentation

Msatar can provide detailed quality testing reports, including raw material certificates, laboratory test reports, fumigation reports, specification guides, commercial invoices, and guarantees, ensuring the quality transparency and traceability of each batch of products.

2.Fine export packaging

In international shipping, the quality of packaging directly affects whether goods can rust, corrode, scratch, deform, or suffer other damages during transport. Therefore, high-quality packaging materials are crucial. Msatar has years of export packaging experience, providing safe and reliable packaging solutions for thousands of businesses. By using fumigated wooden boxes, wooden pallets, and other high-quality packaging materials, our packaging damage rate is only one-third of the industry average.

3.Professional loading solutions

Our experienced order-following team can provide flexible and diverse loading solutions, including options for 20/40-foot containers or bulk ships. Regardless of your cargo specifications and shapes, we can customize a refined loading plan that saves an average of 15% container space, effectively reducing your logistics costs.

Knowledge center for 7A04 aluminum bar

7A04 aluminum bar weight calculator

Use our weight calculator to reliably estimate the weight of aluminum alloy products. From sheets, tubes, bars, to simple profiles, Mastar Metal can provide you with the answers.

First, select an alloy, fill in the other required information, and the system will calculate the weight of the aluminum material for you.

Start by choosing an alloy...

*All weights shown using this metal weight calculator are for guidance only.

Chemical composition for 7A04 aluminum bar

| Element | 7a04 |

| Si | 0.50 |

| Fe | 0.50 |

| Cu | 1.4-2.0 |

| Mn | 0.2-0.6 |

| Mg | 1.8-2.8 |

| Cr | 0.1-0.25 |

| Zn | 5.0-7.0 |

| Ti | 0.10 |

| Remarks | - |

| Others (Each) | 0.05 |

| Others (Total) | 0.15 |

| Al | Rem |

Physical properties of 7A04 aluminum bar

| Properties | 7a04 |

| Density | 2.72 g/cm³ |

| Melting point | 562-646°C |

| Thermal conductivity | 150 W/m·K |

| Coefficient of thermal expansion | 23.2 µm/m·°C |

| Electrical conductivity | 40 % IACS |

Mechanical properties 7A04 aluminum bar

| Properties | 7a04 |

| Tensile strength Rm/Mpa | 530 |

| Yield strength Rp0.2/Mpa | 400 |

| Elongation | 6% |

| Hardness | 156HB |

Heat treatment specification of 7A04 aluminum bar

- Homogenization annealing: heating at 450~465℃; keeping warm for 12~14h; furnace cooling.

- Full annealing: heating at 390~430℃; keeping warm for 30~120min; furnace cooling to 150℃ and air cooling.

- Quenching and aging: quenching at 465~480℃, water cooling; artificial aging (aluminum-clad sheet) 115~125℃24h, (unclad aluminum profile) 135~145℃16h, (semi-finished products) heating at 115~125℃3h for level 1, air cooling at 155~165℃3h for level 2.