7175 aluminum is a heat-treatable forged alloy that offers excellent strength and toughness, combined with outstanding resistance to stress corrosion cracking, making it an ideal choice for aerospace and MRO (Maintenance, Repair, and Overhaul) applications.

Popular products of 7175 aluminum rod

Mastar supplies 7175 aluminum bars in multiple product shapes—including round bar, square bar, flat bar, and hexagonal bars—to support a wide range of aerospace and structural applications. All bar types are available in standard or customized dimensions, ensuring flexibility for CNC machining, forging, or high-load assembly needs.

- 7175 T74 Aluminum Forged Rod

7175-T74 is an aluminum alloy that has undergone solution heat treatment and artificial aging to optimize its mechanical properties. It achieves a balance between tensile strength, stress corrosion resistance, exfoliation corrosion resistance, and fracture toughness. This alloy is suitable for aerospace engineering applications that require high strength and corrosion resistance, such as aircraft structures, aircraft fasteners, and landing gear.

- ASTM B247

- MIL-A-22771

- AMS-QQ-A-367

- 7175 T7452 Aluminum Forged Rod

7175-T7452 is an aluminum alloy that has undergone solution heat treatment and stress relief, followed by artificial aging to enhance its stability. It provides excellent strength and corrosion resistance, making it suitable for high-load applications. 7175-T7452 aluminum forged rod is widely used in aircraft engine parts, turbine blades, and turbine disks.

- ASTM B247

- MIL-A-22771

- AMS-QQ-A-367

- 7175 T7454 Aluminum Forged Rod

7175-T7454 is an aluminum alloy that has undergone solution heat treatment and stress relief, followed by artificial aging to improve stability. It optimizes the alloy's strength and toughness, enhancing its corrosion resistance. The 7175-T7454 aluminum forged rod is well-suited for components such as gears, shafts, and wing tension members.

- ASTM B247

- AMS-QQ-A-367

- 7175 T73511 Aluminum Extruded Bar

7175 T73511 aluminum extruded bar is processed through a special heat treatment process, offering excellent strength and toughness. It provides significant stress corrosion cracking resistance, making it an ideal choice for structural applications and fittings (such as bolts and rivets).

- AMS 4344

7175 aluminum alloy equivalent grades

- UNS A97175

- AG 4,5 MC

- 3.4364

- AlMg4,5Mn

- AW-AlMg4,5Mn0,7

Chemical composition of 7175 aluminum alloy

| Element | 7175(ASTM B247) |

| Si | 0.15 |

| Fe | 0.20 |

| Cu | 1.2-2.0 |

| Mn | 0.1 |

| Mg | 2.1-2.9 |

| Cr | 0.18-0.28 |

| Zn | 5.1-6.1 |

| Ti | 0.10 |

| Others (Each) | 0.05 |

| Others (Total) | 0.15 |

| Al | Rem |

The primary alloying elements in 7175 aluminium include zinc, copper, magnesium, and chromium. Zinc is the main strengthening element that increases strength; copper enhances tensile strength but must be controlled to maintain corrosion resistance; magnesium improves both corrosion resistance and weldability; and chromium further enhances strength and corrosion performance. This makes 7175 aluminum alloy particularly suitable for high-load and demanding applications, such as those in the aerospace industry.

Physical properties of 7175 aluminum alloy

| Physical Property | Value |

| Density | 2.6-2.8 g/cm³ |

| Melting point | 482°C |

| Thermal conductivity | 177 (W/mK) |

| Elastic modulus | 70-80 Gpa |

| Poisson's ratio | 0.33 |

Mechanical properties of 7175 aluminum alloy

| Mechanical Properties | 7175-T74 | 7175-T7452 | 7175-T7454 |

| Tensile Strength, min, ksi | 76.0 | 73.0 | 75.0 |

| Yield strength (0.2 %Offset), min, ksi | 66.0 | 63.0 | 65.0 |

| Elongation E in 2 in. or 4xDia, min, % | 4% | 4% | 4% |

Characteristics of 7150 aluminum bar

- High Mechanical Strength: 7175 aluminum alloy combines high strength and fracture toughness, making it particularly suitable for aerospace and other high-load applications.

- Fracture Toughness: It exhibits excellent fracture toughness, enhancing the durability and reliability of the material.

- Stress Corrosion Cracking Resistance: With outstanding stress corrosion cracking resistance, it ensures safety in harsh environments.

- Heat Treatable: The alloy can be enhanced through heat treatment, making it suitable for various processing methods, including cold working and hot working.

- Good Machinability: It is easy to process, allowing for larger bending radii, making it ideal for forging and die forging.

What can we provide as a high-quality aluminum bar supplier?

- Quality Products: We use high-quality aluminum billets, employing precise alloy and heat treatment processes to optimize product strength and ductility, ensuring uniform cooling and annealing processes. This guarantees high tensile strength and excellent performance.

- Good Roughness Control: Produced through a reverse extrusion process, we control the cooling rate and homogenization treatment, with grain size typically maintained at ≤0.5mm, reducing quality defects and ensuring fine material structure, enhancing product consistency.

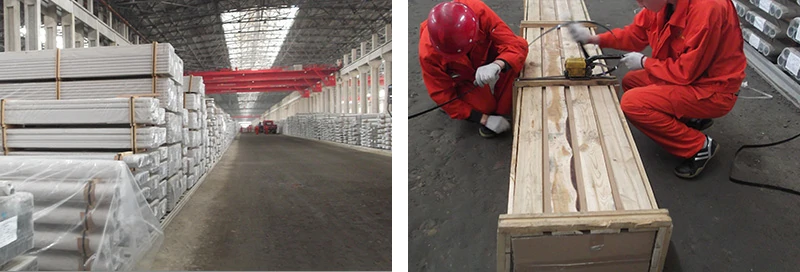

- Delivery Time: With 10,000 tons of stock, we can directly match standard sizes from existing inventory, ensuring fast shipment. Our advanced equipment and professional team help shorten delivery times, providing convenient logistics for on-time delivery.

- Price Advantage: We support both retail and bulk purchases for metal distributors, offering discounts and rebate policies for B2B customers. Our pricing is transparent, ensuring a competitive advantage with equivalent-quality aluminum bars.

- Comprehensive Quality Testing: We strictly execute multiple inspection processes, including tensile strength, elongation performance, ultrasonic testing, and metallographic inspection, ensuring that the aluminum bars meet AMS, EN, and NADCAP certification standards.

- Fine Export Packaging: Using high-quality packaging materials such as wooden crates, wooden boxes, cartons, pallets, plastic coatings, and custom bundling to prevent rust and corrosion during shipping.

- Complete Documentation Reports: We provide detailed quality test reports, including raw material certificates, lab test reports, fumigation reports, specification guides, commercial invoices, and warranty certificates, ensuring the quality of each batch is transparent and traceable.

- Customer Service: We offer comprehensive after-sales service to address customer concerns. Our experienced technical team provides professional consultation and guidance, establishing a robust customer service system to ensure a high-quality service experience.

7075 vs 7175

- Strength and Toughness: 7075 has slightly higher strength, but its toughness is lower than that of 7175. Thus, 7175 is more suitable for high durability requirements in aerospace structures.

- Composition Control: 7175 has stricter controls on iron and silicon content in the alloy to optimize overall strength and toughness.

- Machinability: Both alloys can be cold worked and hot worked, with 7175 achieving similar larger bending radii as 7075.

In addition to 7075 and 7175, Mastar also supplies a full range of high-strength hard aluminum alloys for aerospace and heavy-duty structural applications. These include 7050 for excellent corrosion resistance and fracture toughness, 2024 for superior fatigue performance, and 7475 for components requiring outstanding damage tolerance. This comprehensive selection ensures optimal material solutions for various critical engineering demands.