The 7049A Aluminum Bar is a high-performance forged aluminum alloy recognized for its exceptional resistance to stress corrosion cracking (SCC) and high strength, making it a preferred choice in aerospace, missile, and structural forging fields. Thanks to its heat-treatable properties, 7049 aluminum performs outstandingly under heavy load conditions and is tailored for high-stress structural applications. Its fatigue resistance is comparable to that of 7075 T6 alloy, yet it offers slightly higher toughness.

Click to View the 7049 Aluminum Bar Product Guide.

Msatar provides various production processes for aluminum bars, including extruded bars, cold-worked bars, and forged bars, available in a wide range of sizes and specifications as outlined below:

- 7049 extrusion aluminum bar

- Temper: T6,T6510, T6511

- DIA: 0.4"-16"(10-420mm)

- Spec: EN 755

- 7049 cold finished aluminum bar

- Temper: T6

- DIA: 0.125"-8"(3-200mm)

- Spec: EN 754

- 7049 aluminum forged bar

- DIA: 7.8"-40"(200-1000mm)

- Spec: B247,AMS-QQA-367

- Made by forging process, it has extremely high strength, fatigue resistance and high temperature resistance.

Popular products of 7049 aluminum bar

- 7049A T6 extrusion aluminum bar

- 7049A T6510 extrusion aluminum bar

- 7049A T6511 extrusion aluminum bar

- 7049 T73511 extrusion aluminum bar(AMS 4157)

- 7049 T76511 extrusion aluminum bar(AMS 4159)

- 7049A T6 cold finished aluminum bar

- 7049 T73 aluminum forged bar

- 7049 T7351 aluminum forged bar

As a high-quality aluminum bar supplier, what can we offer you?

- Premium Quality Products: Using high-quality aluminum billets, we employ precise alloying and heat treatment processes to optimize strength and ductility, ensuring uniform cooling and annealing for superior tensile strength and performance.

- Excellent Macro-Structure Control: Produced through reverse extrusion, we manage cooling rates and homogenization processes to keep grain rings within ≤0.5mm, reducing defects and enhancing material consistency and microstructure uniformity.

- On-Time Delivery: With over 10,000 tons of inventory, standard sizes are ready to ship. Our advanced equipment and skilled team ensure short lead times and convenient logistics for on-time delivery.

- Competitive Pricing: Supporting retail and bulk purchases, we provide discounts and rebate programs for bulk buyers. Pricing is transparent, ensuring a cost advantage for aluminum bars of equivalent quality.

- Comprehensive Quality Testing: We conduct multiple inspection steps, including tensile strength, elongation, ultrasonic testing, and metallographic analysis to meet AMS, EN, NADCAP certification standards, ensuring each bar meets the highest quality benchmarks.

- Dedicated Customer Service: We offer full-service support, with experienced technical teams providing expert consultation and guidance. Our service system ensures excellent post-purchase experience and customer satisfaction.

Features of 7049A aluminum bar

- Exceptional Stress Corrosion Cracking Resistance

- High Tensile and Yield Strength

- Heat-Treatable for Enhanced Strength

- Good Weldability and Machinability

Best collaboration fields for 7049A aluminum bar

Aerospace Industry

Aerospace Industry- In aerospace, 7049 aluminum bars are commonly used for structural forgings such as landing gear, gearboxes, and airframe components. Their high strength and stress corrosion resistance make them ideal for meeting the stringent requirements of the aerospace and defense industries.

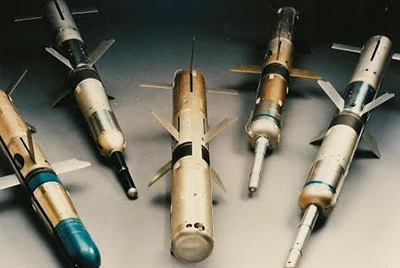

Defense Sector

Defense Sector- For the defense industry, 7049 aluminum alloy is extensively used in missile casings, defensive equipment, and other critical components under high-stress conditions. The alloy's ability to maintain structural integrity under extreme conditions is vital for the safety and reliability of defense systems, making it a preferred material.

Structural Forgings

Structural Forgings- Beyond aerospace and missiles, 7049 aluminum alloy is used in other industries that require high strength and corrosion resistance for industrial equipment such as large structural forgings, industrial machinery components, heavy-duty equipment, and hydraulic cylinders in high-stress applications.

7049 aluminum bar procurement guide

1.Comprehensive documentation

Msatar provides detailed quality testing reports, including raw material certificates, laboratory test reports, fumigation reports, specification guides, commercial invoices, and guarantees, ensuring transparency and traceability of each batch of products.

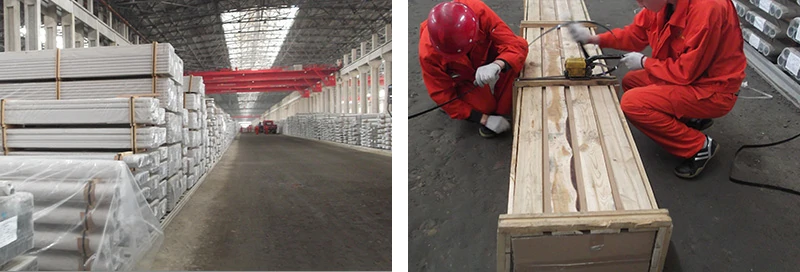

2.Precision export packaging

In international shipping, the quality of packaging materials directly affects whether goods become rusty, corroded, scratched, deformed, or damaged during transit. Therefore, high-quality packaging materials are crucial. Msatar has years of experience in export packaging, providing safe and reliable solutions for thousands of companies. By using fumigated wooden boxes, wooden pallets, and other quality materials, our packaging damage rate is only one-third of the industry average.

3.Professional loading solutions

Our experienced team offers flexible and diverse loading solutions, with options for 20-foot or 40-foot containers or bulk shipping. Regardless of the size or shape of your cargo, we can customize a precise loading plan, saving an average of 15% in container space, thereby reducing your logistics costs.

Knowledge center for 7003 aluminum bar

Standards and specifications of 7049 aluminum bar

- EN 573-3: 2009 Aluminium and aluminium alloys. Chemical composition and form of wrought products. Chemical composition and form of products

- EN 755-2:2008 Aluminium and aluminium alloys. Extruded rod/bar, tube and profiles. Mechanical properties

- EN 754-2: 2008 Aluminium and aluminium alloys. Cold drawn rod/bar and tube. Mechanical properties

Chemical composition of 7049 7049A aluminum bar

| Element | 7049 (GB/T 3190) | EN AW- 7049A (EN 573) |

| Si | 0.25 | 0.40 |

| Fe | 0.35 | 0.50 |

| Cu | 1.2-1.9 | 1.2-1.9 |

| Mn | 0.20 | 0.50 |

| Mg | 2.0-2.9 | 2.1-3.1 |

| Cr | 0.10-0.22 | 0.05-0.25 |

| Zn | 7.2-8.2 | 7.2-8.4 |

| Ti | 0.10 | 0.01-0.06 |

| Remarks | - | 0.25 Zr+Ti |

| Others (Each) | 0.05 | 0.05 |

| Others (Total) | 0.15 | 0.15 |

| Al | Rem | Rem |

Physical properties of 7049 7049A aluminum bar

| Properties | 7049 | 7049A |

| Density | 2.84 g/cm³ | 2.84 g/cm³ |

| Melting point | 480 - 640°C | 430 - 640°C |

| Thermal conductivity | 130 W/m·K | 130 W/m·K |

| Coefficient of thermal expansion | 23 µm/m·°C | 24 µm/m·°C |

| Electrical conductivity | 36 % IACS | 36 % IACS |

Mechanical properties of 7049 T73/T7351 aluminum bar

| Properties | T73 | T7352 |

| Tensile strength Rm/Mpa | 530 | 510 |

| Yield strength Rp0.2/Mpa | 450 | 420 |

| Elongation | 6.2% | 7% |

| Hardness | 140 | 140 |

Mechanical properties of 7049A T6/T6510/T6511aluminum bar

| Property | Diameter/mm (EN 755) | |||

| ≤<100 | 100<D≤100 | 100<D≤100 | 100<D≤100 | |

| Tensile strength Rm/Mpa | 610 | 560 | 520 | 450 |

| Yield strength Rp0.2/Mpa | 530 | 500 | 430 | 400 |

| Elongation | 4-5% | 5% | 5% | 5% |

| Hardness | 170 | 170 | 170 | 170 |

7049 aluminum alloy vs 7075 aluminum alloy: comparison and analysis

7049 Aluminum Alloy is a high-strength forged aluminum alloy with exceptional stress corrosion cracking resistance, ideal for parts requiring high static and fatigue strength. It is particularly suited for aerospace and missile applications, including landing gear, gearboxes, and hydraulic cylinders.

7075 Aluminum Alloy is another well-known high-strength aluminum widely used in aerospace, recognized for its high strength, good mechanical properties, and moderate corrosion resistance. It's often chosen for lightweight structural components such as aircraft frames and body structures.

Chemical Composition

7049 contains higher levels of zinc and magnesium compared to 7075, providing an advantage in strength and stress corrosion resistance, though it is slightly less machinable than 7075.

Mechanical Properties

While both alloys exhibit similar tensile and yield strength, 7049 surpasses 7075 in stress corrosion resistance and toughness, whereas 7075 offers slightly better machinability.

Stress Corrosion Cracking Resistance

Stress corrosion resistance is one of the most significant differences between these two alloys.

- 7049-T6 is designed specifically for applications requiring higher stress corrosion resistance, making it an optimal choice for critical aircraft parts in humid environments.

- 7075-T6, despite its high strength, is more susceptible to stress corrosion cracks in humid or high-stress conditions, so for applications where extreme reliability is necessary, 7049 may be the preferred choice.

Applications

- 7049 is ideal for components requiring high static and fatigue strength, such as aircraft landing gear, gearboxes, hydraulic cylinders, and extrusions. Its corrosion resistance in high-stress environments makes it particularly suitable for critical parts in aircraft and missiles.

- 7075 is widely used in aircraft body structures, frames, and other areas demanding lightweight materials with high strength. It is typically chosen for high-strength applications where environmental corrosion is less of a concern.

For users with applications involving high-stress and high-corrosion environments like critical aerospace and missile components, 7049 aluminum alloy is ideal. Its toughness and stress corrosion resistance make it more reliable for high-risk environments. On the other hand, for applications requiring high strength with easier machinability, such as aircraft bodies or structural frames, 7075 aluminum alloy remains the industry's top choice due to its machinability and extensive use record.