The 7004 aluminum bar stands out as an exceptional member of the 7xxx series aluminum alloys, specifically designed for applications requiring high tensile strength, good weldability, and resistance to stress corrosion. Its chemical composition is meticulously engineered, particularly the magnesium and zinc content, which ensures excellent performance in welding and stress corrosion environments, while also providing high tensile strength. Additionally, the incorporation of elements such as zirconium, manganese, and chromium enhances its overall weldability and corrosion resistance. It is widely used in industries where strength and weldability are critical, including automotive, aerospace, and military sectors.

Click here to view the 7004 aluminum bar product guide.

7004 aluminum bar introduction

Alloy: 7004

Equivalent Name: UNS A97004

Diameter: 5-420 mm

Length: Customizable

Standards: ASTM B221, ISO 6361

What can we offer as a high-quality aluminum bar supplier?

- Quality Products: We use high-quality aluminum bar billets and employ precise alloy and heat treatment processes to optimize product strength and ductility, ensuring uniform cooling and annealing. This guarantees high tensile strength and excellent performance of the products.

- Good Roughness and Precision Control: Produced through reverse extrusion processes, we control cooling rates and homogenization treatment, typically maintaining grain sizes at ≤0.5 mm, which reduces quality defects and enhances material consistency.

- Delivery Time: With a stock of tens of thousands of tons, we can directly match standard sizes from existing inventory, ensuring rapid delivery. Advanced equipment and a professional team help shorten delivery times, providing convenient logistics and on-time arrival.

- Price Advantage: We support retail and bulk purchasing for metal distributors, offering discounts and rebate policies for B2B customers. Our pricing is transparent, ensuring price advantages for products of equal quality.

- Comprehensive Documentation: We provide detailed quality testing reports, including raw material certificates, laboratory test reports, fumigation reports, specification guides, commercial invoices, and guarantees, ensuring transparency and traceability of each batch of products.

- Customer Service: We offer comprehensive after-sales services to address customer concerns. Our experienced technical team provides professional consultation and guidance, establishing a robust customer service system to ensure a quality service experience.

Features of 7004 aluminum bar

High Strength and Formability: The 7004 aluminum alloy achieves a good balance between strength and formability. Compared to 6000 series alloys (like 6061 and 6063), it has higher strength, especially in the solution heat-treated and T6 states, with tensile strength exceeding 370 MPa. This makes it highly competitive for applications requiring high strength while retaining some formability, suitable for manufacturing complex components.

Stress Corrosion Cracking Resistance: The addition of trace elements such as zirconium and chromium gives the 7004 aluminum alloy good stress corrosion resistance, allowing it to maintain a longer lifespan even in harsh environments.

Excellent Corrosion Resistance: Like other aluminum alloys, 7004 aluminum alloy forms a natural oxide protective layer when exposed to air, significantly enhancing its corrosion resistance, especially suitable for structural components exposed to harsh environments, such as marine or high-humidity settings.

Outstanding Weldability: Due to its unique compositional design, the 7004 aluminum alloy exhibits excellent weldability. It shows superior crack resistance in welding applications, reducing the risk of weld seam cracking, making it ideal for use in structures where high welding strength is required.

Heat Treatability: The 7004 aluminum alloy can further improve its mechanical properties through various heat treatment methods, especially through solution treatment and aging, significantly enhancing strength and hardness. This flexibility allows the material to meet different strength requirements in various applications.

Best collaboration fields for 7004 aluminum bar

Aerospace Industry

Aerospace Industry- In the aerospace industry, 7004 aluminum alloy is commonly used to manufacture aircraft structural components such as wings, fuselage frames, and skin panels. Its excellent strength-to-weight ratio allows aircraft to reduce weight while ensuring strength. The good weldability ensures the connection strength of critical components.

Automotive Industry

Automotive Industry- 7004 aluminum alloy is often used to manufacture body panels, chassis components, and suspension parts. Its high strength enables vehicles to maintain body rigidity while reducing weight, which not only improves fuel efficiency but also enhances collision safety.

Military Equipment

Military Equipment- 7004 aluminum alloy is also widely used in the military field, particularly in vehicle armor, military bridges, and other heavy-duty military equipment. Its high strength and corrosion resistance perform excellently in extreme environments, meeting military equipment's needs for high strength, lightweight, and durability.

7004 aluminum bar procurement guide

1.Comprehensive documentation

Msatar can provide detailed quality testing reports, including raw material certificates, laboratory test reports, fumigation reports, specification guides, commercial invoices, and guarantees, ensuring the quality transparency and traceability of each batch of products.

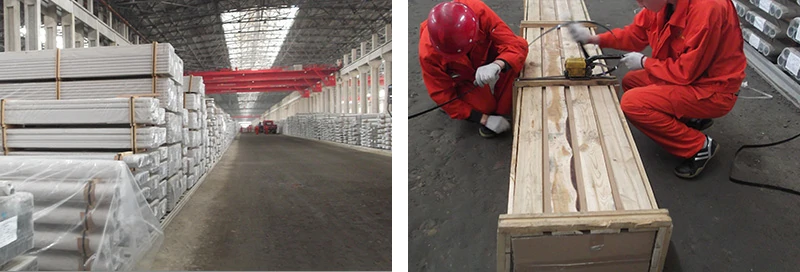

2.Fine export packaging

In international shipping, the quality of packaging directly affects whether goods can rust, corrode, scratch, deform, or suffer other damages during transport. Therefore, high-quality packaging materials are crucial. Msatar has years of export packaging experience, providing safe and reliable packaging solutions for thousands of businesses. By using fumigated wooden boxes, wooden pallets, and other high-quality packaging materials, our packaging damage rate is only one-third of the industry average.

3.Professional loading solutions

Our experienced order-following team can provide flexible and diverse loading solutions, including options for 20/40-foot containers or bulk ships. Regardless of your cargo specifications and shapes, we can customize a refined loading plan that saves an average of 15% container space, effectively reducing your logistics costs.

7004 aluminum bar knowledge center

Chemical composition of 7004 aluminum bar

| Element | Value |

| Si | 0.25 |

| Fe | 0.35 |

| Cu | 0.05 |

| Mn | 0.2-0.7 |

| Mg | 1.0-2.0 |

| Cr | 0.05 |

| Zn | 3.8-4.6 |

| Ti | 0.05 |

| Zr | 0.1-0.2 |

| Others (Each) | 0.05 |

| Others (Total) | 0.15 |

| Al | Rem |

Physical properties of 7004 aluminum bar

| Properties | Value |

| Density | 2.77 g/cm³ |

| Melting point | 475-635°C |

| Thermal conductivity | 130 W/m·K |

| Coefficient of thermal expansion | 23.2 µm/m·°C |

Mechanical properties of 7004 aluminum bar

| Properties | Value |

| Tensile strength Rm/ Mpa | 370 |

| Yield strength Rp0.2/ Mpa | 330 |

| Elongation | 10 % |

| Hardness | 95-110 |

How is the stress corrosion cracking resistance of 7004 aluminum alloy?

7004 aluminum alloy exhibits good stress corrosion cracking resistance, attributed to the addition of trace elements like zirconium and chromium in its chemical composition. These elements help form a more stable grain structure within the alloy, enhancing the material's corrosion resistance in high-stress environments. Its balanced strength, corrosion resistance, and weldability make it particularly suitable for applications that require high strength while facing corrosive stress challenges.

How is the weldability of 7004 aluminum alloy?

7004 aluminum alloy shows excellent weldability during the welding process, especially suitable for techniques such as Friction Stir Welding (FSW) and Gas Tungsten Arc Welding (GTAW).

- In Friction Stir Welding, 7004 aluminum alloy can minimize weld crack and porosity issues by optimizing welding parameters, resulting in uniform weld joint strength. Post-weld heat treatment, such as artificial aging, can further enhance the tensile strength and toughness of the welded area, ensuring high strength and durability of the welds.

- During GTAW, 7004 aluminum alloy exhibits a unique weld solidification structure. Due to the fluidity of the weld pool and temperature gradient during welding, slight structural asymmetry may occur, but the overall welding quality remains excellent. By adjusting parameters such as welding speed and current, welding strength and uniformity can be further optimized.

What welding wire is best for welding 7004 aluminum alloy?

When welding 7004 aluminum alloy, it is recommended to use 5356 aluminum wire or 4047 aluminum wire:

- 5356 aluminum wire: Its high magnesium content ensures good strength and corrosion resistance, making it particularly suitable for high-strength welding scenarios, such as aerospace or marine environments.

- 4047 aluminum wire: Due to its high silicon content, 4047 wire offers good fluidity and low crack sensitivity, making it ideal for applications requiring high-quality welds.

Is heat treatment required after welding 7004 aluminum alloy?

Heat treatment is typically required after welding. Through solution treatment and artificial aging, the softening effect in the heat-affected zone can be eliminated, restoring the material's strength and further enhancing the mechanical properties of the weld.