The 6105 aluminum rod is known for its good corrosion resistance and medium strength, available in two temper states: 6105-T1 and 6105-T5. The T1 temper is suitable for bending, while the T5 temper offers higher mechanical performance.

The higher silicon content in the 6105 alloy makes it easier to machine, making it particularly suitable for manufacturing complex-shaped products.

Specifications of 6105 aluminum bars

ASTM B221

Size range of 6105 aluminum bars

6105 Aluminum Round Rod Dimensions

6105 Aluminum Round Rod Dimensions- Diameter: 1/8 inch - 8 inches

- Length: 1 - 6 m (Customization)

6105 Flat Bar Dimensions

6105 Flat Bar Dimensions- Thickness: 1/8 inch - 2 inches

- Width: 1 inch - 12 inches

- Length: 1 - 6 m (Customization)

6105 Aluminum Square Rod Dimensions

6105 Aluminum Square Rod Dimensions- Side Length: 1/8 inch - 4 inches

- Length: 1 - 6 m (Customization)

6105 Aluminum Hex Rod Dimensions

6105 Aluminum Hex Rod Dimensions- Side Length: 1/8 inch - 2 inches

- Length: 1 - 6 m (Customization)

In addition to 6105 aluminum bars, Mastar also supplies a wide range of aluminum bar alloys in various shapes such as round bars, square bars, flat bars, and hex bars. If you are looking for alternatives with similar machinability or mechanical strength, feel free to explore our whole aluminum bar product pages or contact us for assistance.Quick Quote

Chemical composition of 6105 aluminum bar

| Chemical Element | % Present |

| Si | 0.60 - 1.0 |

| Fe | 0.35 max |

| Cu | 0.10 max |

| Mn | 0.1 max |

| Mg | 0.45 - 0.8 |

| Cr | 0.10 max |

| Zn | 0.10 max |

| Ti | 0.10 max |

| Other (Each) | 0.05 max |

| Others (Total) | 0.15 max |

| Aluminium (Al) | Balance |

Physical properties of 6105 aluminum bar

| Physical Property | Value |

| Density | 2.69 g/cm³ |

| Melting Point | 649 °C |

| Thermal Expansion | 21.8 x10^-6 /K |

| Modulus of Elasticity | 70 GPa |

| Thermal Conductivity | 176 W/m.K |

Mechanical properties of 6105 aluminum bar

| Temper | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation | Electrical Conductivity |

| T1 | 190 | 120 | 16% | 46% IACS |

| T5 | 280 | 270 | 9% | 50% IACS |

Applications of 6105 aluminum bar

Due to its excellent corrosion resistance and medium strength, 6105 aluminum is widely used in various industrial fields.Quick Quote

- Ladders

- Seamless Structural Tubes

- Automotive Connectors

- Handrail Tubes

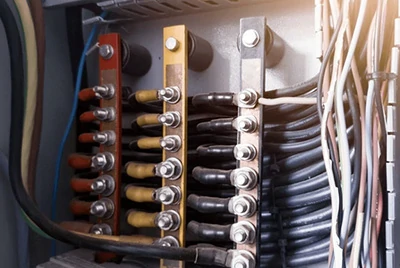

- Electrical Bus Conductors (for enclosed bus electrical systems)

- Construction and Building

- Durable Consumer Goods

- Fixtures and Frames

- Marine Applications

- Displays, Signage, and Advertising

- Platforms

Various anodizing processes for 6105 aluminum bar

The 6105 aluminum alloy exhibits good anodizing properties, making it compatible with various aluminum anodizing processes.

- Clear Anodizing: Preserves the natural metallic color of the aluminum alloy, suitable for applications where appearance is important.

- Colored Anodizing: Enhances aesthetics, widely used in construction and consumer products.

- Hard Anodizing: Creates a thicker oxide layer, improving wear resistance, suitable for high-durability applications.

Machining recommendations for 6105 aluminum bars

Machining 6105 aluminum is relatively straightforward; however, it requires higher cutting speeds compared to other aluminum alloys due to its higher strength and hardness.

It is recommended to use carbide tools specifically designed for machining hard materials (such as titanium or stainless steel), as these tools have superior wear resistance compared to standard HSS tools, effectively increasing machining efficiency.

Additionally, using coolant can significantly reduce tool wear and extend tool life, as it helps dissipate heat generated during the cutting process more effectively.

Therefore, selecting the right tools and machining conditions will help optimize machining results and improve production efficiency.

Welding recommendations for 6105 aluminum bars

- Preheat the Material: It is essential to preheat the material before welding to prevent cracking due to thermal shock.

- Choose Appropriate Filler Material: Depending on the type of welding process, use either 4043 aluminum filler rods or 5356 aluminum filler rods.

- Post-Weld Heating: After welding, it is crucial to perform post-weld heating on the workpiece to prevent cracking caused by improper cooling rates.

- Strength Reduction: The heat from welding may reduce the strength of the welded area.

Quality inspection report — traceable

Our products undergo rigorous quality control, providing a complete set of quality inspection reports.

- Ultrasonic Testing: Ensures no internal defects

- Chemical Composition Analysis: Complies with industry standards

- Mechanical Performance Testing: Validates product strength

- Non-Destructive Testing: Thoroughly identifies potential issues

- Visual Inspection: Striving for perfection

- Traceability Records: Fully traceable throughout the process

Comparison of 6105 aluminum and 6061 aluminum

Compared with 6061, 6105 aluminum bar offers better extrudability but slightly lower strength, making it suitable for lightweight and precision-shaped profiles.

- 6105 aluminum contains a higher silicon content, while 6061 aluminum has a lower silicon content.

- 6105 aluminum is easier to extrude, making it suitable for manufacturing complex shapes.

- The yield strength and tensile strength of 6105 aluminum in the T5 temper are similar to those of 6061-T6.

- Both 6105 and 6061 aluminum can be welded or brazed.

To explore more options based on 6105's extrusion-friendly properties, see our selection of 6105 aluminum bar products and related shapes below.