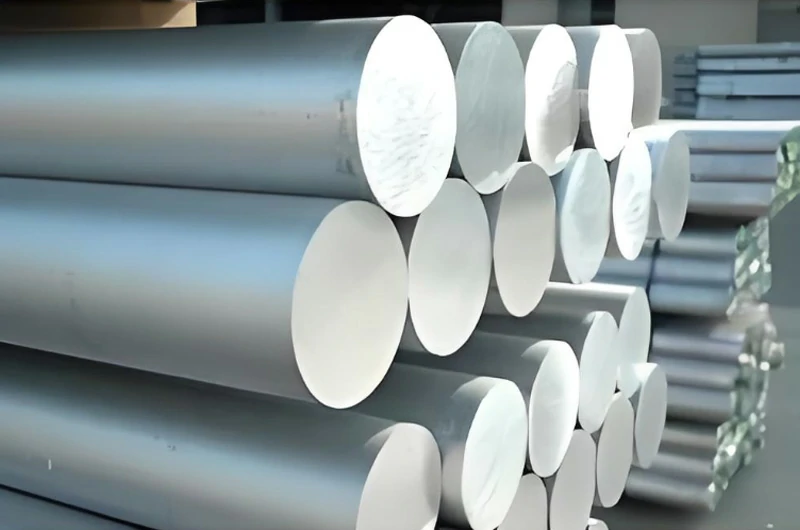

The 6066 Aluminum Bar is an aluminum alloy used for welded structural forgings and extruded components, extensively applied in automotive manufacturing, structural applications, radiators, and high-end bicycles. 6066 aluminum is favored for its exceptional strength and corrosion resistance, as well as its structural stability, durability, and adaptability to complex machining processes. Whether for high-strength welded structures or lightweight designs, 6066 aluminum alloy provides reliable performance assurance.

Click to view the 6066 Aluminum Bar product guide

Mastar can supply various processes of bars, including extruded bars and forged bars, with specific size ranges as follows:

- 6066 extrusion aluminum bar

- Temper: O,T4,T6,T4511,T6511

- DIA: 0.4"-16"(10-420mm)

- Spec: ASTM B221, EN 573

- 6066 cold finished aluminum bar

- Temper: T4

- DIA: 0.2"-8"(5-200mm)

- Spec: AMS4343,EN 573

- 6066 aluminum forged bar

- DIA: 7.8"-40"(200-1000mm)

- Spec: ASTM B247

- Produced through forging, it possesses extremely high strength, fatigue resistance, and high-temperature durability.

6066 Aluminum bar - popular products

- 6066 O extrusion aluminum bar

- 6066 T4/T4511 extrusion aluminum bar

- 6066 T6/T6511 extrusion aluminum bar

- 6066 T4 cold finished aluminum bar

- 6066 T6 aluminum forged bar

- 6066 aluminum round bar

- 6066 aluminum square bar

- 6066 aluminum flat bar

- 6066 large diameter aluminum bar

In addition to 6063 aluminum bars, Mastar also supplies a wide range of aluminum bar alloys in various shapes such as round bars, square bars, flat bars, and hex bars. If you are looking for alternatives with similar machinability or mechanical strength, feel free to explore our whole aluminum bar product pages or contact us for assistance.Quick Quote

What can we offer as a high-quality aluminum bar supplier?

- Quality Products: We use high-quality aluminum bar billets and employ precise alloy and heat treatment processes to optimize product strength and ductility, ensuring uniform cooling and annealing. This guarantees high tensile strength and excellent performance of the products.

- Good Roughness and Precision Control: Produced through reverse extrusion processes, we control cooling rates and homogenization treatment, typically maintaining grain sizes at ≤0.5 mm, which reduces quality defects and enhances material consistency.

- Delivery Time: With a stock of tens of thousands of tons, we can directly match standard sizes from existing inventory, ensuring rapid delivery. Advanced equipment and a professional team help shorten delivery times, providing convenient logistics and on-time arrival.

- Price Advantage: We support retail and bulk purchasing for metal distributors, offering discounts and rebate policies for B2B customers. Our pricing is transparent, ensuring price advantages for products of equal quality.

- Comprehensive Documentation: We provide detailed quality testing reports, including raw material certificates, laboratory test reports, fumigation reports, specification guides, commercial invoices, and guarantees, ensuring transparency and traceability of each batch of products.

- Customer Service: We offer comprehensive after-sales services to address customer concerns. Our experienced technical team provides professional consultation and guidance, establishing a robust customer service system to ensure a quality service experience.

6066 Aluminum bar features

- Outstanding Strength and Corrosion Resistance

- Good Machinability, suitable for various machining processes

- Excellent Weldability, ideal for complex structural components

- Significantly Enhanced Performance after heat treatment

With its combination of strength, weldability, and heat-treatable performance, 6066 aluminum bar shares key advantages with several other high-performance aluminum bar alloys used in structural, aerospace, and precision-machined components.

Best applications for 6066 aluminum bar

Aerospace Structural Components

Aerospace Structural Components- In the aerospace field, the strength and corrosion resistance of 6066 aluminum make it an ideal choice for manufacturing wings, support structures, and other critical components. It maintains good structural integrity under high-stress conditions.

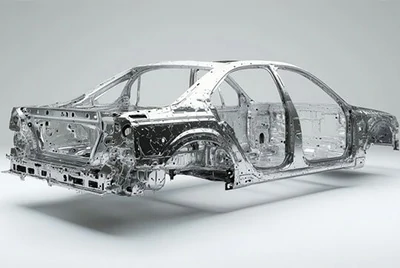

Automotive Manufacturing

Automotive Manufacturing- In automotive manufacturing, 6066 aluminum alloy is commonly used for producing frames, aerodynamic devices, and luggage rack rails. Its high strength and good machinability effectively enhance vehicle safety and fuel efficiency.

High-End Bicycles

High-End Bicycles- 6066 aluminum alloy is widely used in the production of high-performance bicycle frames, such as the Merida Triathlon and Strida Rim400 frames. The 6066 alloy is lightweight yet robust, providing a comfortable riding experience while ensuring frame durability.

Radiators & Heat Exchangers

Radiators & Heat Exchangers- The excellent thermal conductivity of 6066 aluminum alloy makes it suitable for radiator applications. Radiators are commonly used to dissipate heat from electronic devices, such as computer processors, LEDs, and power modules.

High-End Window and Door Manufacturing

High-End Window and Door Manufacturing- Due to its high strength, corrosion resistance, and good machinability, 6066 aluminum alloy is extensively used in high-end window and door manufacturing, such as the Mihai high-performance windows and Warren 75 inward-opening windows. Its outstanding performance makes it an ideal choice for premium windows and doors.

Structural Applications

Structural Applications- 6066 aluminum can be used in various structural applications requiring lightweight materials with good strength. This includes bridges, building facades, roof structures, and supporting beams.

6066 aluminum bar procurement guide

1.Comprehensive documentation

Msatar can provide detailed quality testing reports, including raw material certificates, laboratory test reports, fumigation reports, specification guides, commercial invoices, and guarantees, ensuring the quality transparency and traceability of each batch of products.

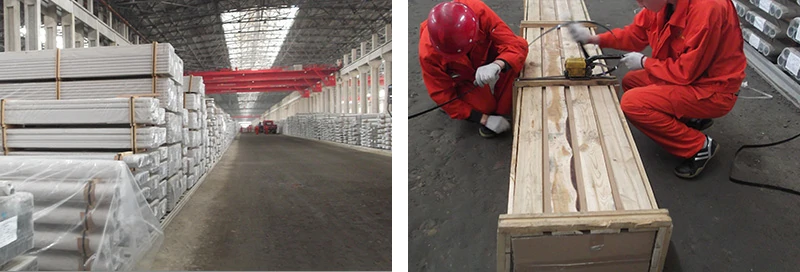

2.Fine export packaging

In international shipping, the quality of packaging directly affects whether goods can rust, corrode, scratch, deform, or suffer other damages during transport. Therefore, high-quality packaging materials are crucial. Msatar has years of export packaging experience, providing safe and reliable packaging solutions for thousands of businesses. By using fumigated wooden boxes, wooden pallets, and other high-quality packaging materials, our packaging damage rate is only one-third of the industry average.

3.Professional loading solutions

Our experienced order-following team can provide flexible and diverse loading solutions, including options for 20/40-foot containers or bulk ships. Regardless of your cargo specifications and shapes, we can customize a refined loading plan that saves an average of 15% container space, effectively reducing your logistics costs.

UNS A96066 aluminum bar knowledge center

Equivalent name of 6066 Aluminum Alloy

- BS 2 L84

- UNS A96066

- ISO AlMg0.7Si

Specification for 6066 Aluminum Bar

- AMS QQ-A-200/10A - Aluminum Alloy 6066, Bar, Rod, Shapes, Tube, and Wire, Extruded

- ASTM B221 - Aluminum and Aluminum-Alloy Extruded Bars, Rods, Wire, Profiles, and Tubes

- ASTM B247 - Standard Specification for Aluminum and Aluminum-Alloy Die Forgings, Hand Forgings, and Rolled Ring Forgings

Chemical composition of 6066 Aluminum Bar

| Element | UNS A96066 |

| Si | 0.9-1.8 |

| Fe | 0.50 |

| Cu | 0.7-1.2 |

| Mn | 0.6-1.1 |

| Mg | 0.8-1.4 |

| Cr | 0.40 |

| Zn | 0.25 |

| Ti | 0.20 |

| Remarks | - |

| Others (Each) | 0.05 |

| Others (Total) | 0.15 |

| Al | Rem |

Physical properties of 6066 Aluminum Bar

| Properties | 6066 |

| Density | 2.72 g/cm³ |

| Melting point | 562-646°C |

| Thermal conductivity | 150 W/m·K |

| Coefficient of thermal expansion | 23.2 µm/m·°C |

| Electrical conductivity | 40 % IACS |

Mechanical properties of 6066 aluminum bar

| Properties | O | T4,T4510,T4511 | T42 | T6,T6510,T6511 | T62 |

| Tensile strength Rm/Ksi | 29 | 40 | 40 | 50 | 50 |

| Yield strength Rp0.2/Ksi | 18 | 25 | 24 | 45 | 42 |

| Elongation | 16% | 14% | 14% | 8% | 8% |

6060 vs 6066

Compared with 6060, 6066 aluminum bar offers higher strength and better heat treatment response, making it more suitable for demanding structural applications.

- Strength: 6066 aluminum exhibits significantly higher strength compared to 6060. After T6 treatment, 6066 has greater tensile strength, making it suitable for high-strength structural components. 6060 has lower strength, typically used in applications with less demanding strength requirements.

- Machinability: 6060 aluminum alloy has better machinability, weldability, and formability, making it suitable for extrusion and construction applications. 6066 can also be machined but is more commonly used in scenarios requiring strength.

- Applications: 6060 is often found in construction and decorative materials, while 6066 is more frequently used in high-demand mechanical structures, aerospace components, and bicycle frames.

6061 vs 6066

6066 and 6061 have a high similarity in alloy composition, reaching up to 98%, but 6066 outperforms 6061 in strength:

- Strength: 6066 aluminum alloy has a higher tensile strength compared to 6061, particularly after T6 treatment, making 6066 more suitable for high-stress applications. While 6061 has slightly lower strength, it still possesses good mechanical properties.

- Machinability and Weldability: 6061 offers slightly better machinability and weldability than 6066, making it suitable for a wide range of industrial uses. While 6066 also has good weldability, its high strength makes it more appropriate for use in high-stress environments.

- Applications: 6061 is common in automotive parts and building frames, while 6066 is more frequently used in aerospace, pressure vessels, and high-strength mechanical components.