6063 aluminum bar is a high-plasticity alloy in the Al-Mg-Si system, also known as the architectural alloy. It features excellent extrusion performance, good surface finish, and high corrosion resistance. This alloy is easy to weld and delivers outstanding results after anodizing. As a result, it is widely used in various architectural profiles, window and door frames, heat sinks, and electrical applications.

As a professional aluminum supplier, Mastar can customize products based on EN, ASTM, and AMS standards according to customer requirements. We can supply extruded bars, cold-worked bars, and casting billets for extrusion. All materials leaving the warehouse undergo strict testing, and we provide a product quality inspection report as proof of quality.

- 6063 extrusion aluminum bar

- Temper: O, T4, T5, T6, T66

- DIA: 0.4"-16"(10-420mm)

- Spec: AMS 4156, EN 755

- Extruded Rod Size Chart

- 6063 aluminum cold-finished bar

- Temper: O, T4, T6, T66

- DIA: 0.125"-8"(3-200mm)

- Spec: EN 754

- Cold Finished bar size Chart

- 6063 aluminum cast billets bar

- Temper: F

- DIA: 4.8"-53"(124-1350mm)

- Material used for subsequent extrusion production

If you need more detailed information or have custom requirements for 2017 aluminum bars, feel free to contact our professional team. We will help you find the best solution. Quick Quote

Popular Products of 6063/6063A aluminum bar

6063/6063A O aluminum rod bar

6063 O is the annealed condition of 6063 aluminum bars, offering the lowest strength and the highest ductility. Due to its excellent formability and corrosion resistance, this temper is ideal for applications requiring complex forming or bending, such as pipes in irrigation systems.

6063/6063A T4 aluminum rod bar

6063 T4 aluminum bars undergo solution heat treatment followed by natural aging. This temper offers ductility just below that of the O temper, combining good formability with moderate strength. It is suitable for complex forming applications, commonly used in bent components like elbows and rails, and also in hydraulic-formed tubes in automotive chassis.

6063/6063A T5 aluminum rod bar

6063 T5 aluminum rod bar is air-cooled after extrusion and artificially aged to achieve the desired mechanical properties. With moderate strength and relatively low hardness (Webster hardness 8-12), it is easier to machine and form, making it ideal for applications that don't require high strength but need good machinability, such as architectural decorative parts like covers, trim, and window profiles.

6063 T52 aluminum rod bar

The 6063 T52 aluminum bar is air-cooled and artificially aged to enhance its mechanical properties. It offers excellent formability, good corrosion resistance, and weldability, making it well-suited for extrusion processes. It is widely used in outdoor architectural applications, such as curtain walls, window frames, and decorative profiles.

6063/6063A T6 aluminum rod bar

The 6063 T6 aluminum rod bar is solution heat-treated, water-quenched, and artificially aged to increase hardness (Webster hardness ≥13.5). The T6 temper offers higher strength and hardness compared to T5, making it suitable for applications that require higher mechanical stress, such as main load-bearing parts of curtain walls, support frames, rail transit profiles, and railing posts.

6063 T66 aluminum rod bar

The 6063 T66 aluminum rod bar undergoes solution heat treatment and artificial aging, with special control of the manufacturing process to achieve mechanical properties superior to T6. It boasts excellent mechanical properties and corrosion resistance, making it suitable for high-strength architectural profiles and load-bearing structures that require stability and durability.

Is your project timeline tight? Are production cycles not aligning with your engineering schedule? Check the 6063 aluminum bar stock inventory now!

Mastar offers various shapes of EN AW-6063 aluminum bar

What shape of 6063 aluminum bar do you need? Mastar offers a full range of standard shapes! We can also customize special cross-sections to meet your specific requirements.Quick Quote

- 6063 aluminum round bar

- Temper: O, T4, T5, T52, T6, T66

- Diameter: 5-420mm

- Length: 6m, cut to size

- 6063 aluminum square bar

- Temper: T4, T6

- Size: 10x10-200x200mm

- Length: 6m, cut to size

- 6063 aluminum rectangle/flat bar

- Temper: T4, T5, T6

- Size: 10x12-100x250mm

- Length: 6m, cut to size

- 6063 aluminum hexagonal bar

- Temper: T6

- Diameter: 5-25mm

- Length: 2.5m, cut to size

In addition to 6063 aluminum bars, Mastar also supplies a wide range of aluminum bar alloys in various shapes such as round bars, square bars, flat bars, and hex bars. If you are looking for alternatives with similar machinability or mechanical strength, feel free to explore our whole aluminum bar product pages or contact us for assistance.Quick Quote

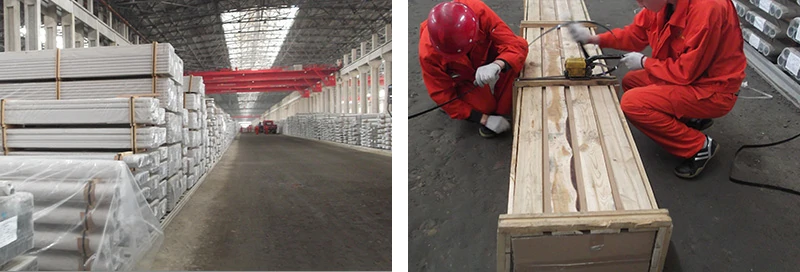

What can we offer you as a high-quality aluminum bar supplier?

- Price Advantage: We support both retail and bulk purchases for metal distributors, offering discounts and rebate policies for bulk buyers. Our pricing is transparent, ensuring a competitive price for aluminum bars of the same quality.

- Delivery Time: With tens of thousands of tons of stock, standard sizes can be quickly matched from inventory, ensuring fast delivery. Our advanced equipment and expert team reduce lead times, offering convenient logistics and on-time delivery.

- Premium Products: We use high-quality aluminum billets, employing precise alloying and heat treatment processes to optimize the strength and ductility of the product. Uniform cooling and annealing processes are guaranteed, ensuring high tensile strength and superior performance.

- Excellent Grain Control: Our reverse extrusion process controls cooling rates and homogenization treatments, typically keeping grain size at ≤0.5mm, which minimizes defects and enhances the consistency and fine texture of the material.

- Comprehensive Quality Inspection: We strictly follow multiple inspection procedures, including tensile strength, elongation, ultrasonic testing, and metallographic inspection, ensuring that our aluminum bars meet AMS, EN, and NADCAP standards before shipping.

- Customer Service: We provide full after-sales support, resolving any customer concerns. Our experienced technical team offers professional consultation and guidance, creating a comprehensive customer service system that ensures a top-notch service experience.

Chemical composition of 6063/6063A aluminum rod bar

| Element | EN AW-6063 | EN AW-6063A |

| Si | 0.20-0.6 | 0.30-0.6 |

| Fe | 0.35 | 0.15-0.35 |

| Cu | 0.1 | 0.1 |

| Mn | 0.1 | 0.15 |

| Mg | 0.45-0.9 | 0.6-0.9 |

| Cr | 0.1 | 0.05 |

| Zn | 0.1 | 0.15 |

| Ti | 0.1 | 0.1 |

| Others (Each) | 0.05 | 0.05 |

| Others (Total) | 0.15 | 0.15 |

| Al | Rem | Rem |

The alloy compositions of EN AW-6063 and EN AW-6063A are quite similar, with 6063A often considered a variant of 6063. The key differences are as follows:

- Si: The lower limit of silicon content in 6063A is slightly higher, which helps increase the alloy's strength.

- Fe: The iron content in 6063A is lower, reducing the risk of brittleness in the material.

- Mn: The manganese content in 6063A is slightly higher, which improves corrosion resistance.

- Mg: The upper limit of magnesium content in 6063A is higher, further enhancing the material's hardness and strength.

In general, 6063A has higher strength, making it suitable for applications requiring higher load-bearing capacity while maintaining the same surface finish and anodizing properties. Additionally, the slightly higher manganese content in 6063A boosts its corrosion resistance, making it ideal for use in harsh environments.

Physical properties of 6063/6063A aluminum rod bar

| Physical Property | Value |

| Density | 2.70 g/cm³ |

| Melting Point | 600℃ |

| Thermal Expansion | 23.5 x10^-6 /K |

| Modulus of Elasticity | 69.5 GPa |

| Thermal Conductivity | 200 W/m.K |

| Electrical Resistivity | 0.035 x10^-6Ω.m |

Mechanical properties of 6063/6063a aluminum rod bar

6063 aluminum rod bar

| Mechanical Properties | O/H111 | T4 | T5 | T6 | T66 |

| Tensile strength Rm/Mpa | 130 | 130 | 175 | 215 | 245 |

| Yield strength Rp0.2/Mpa | - | 65 | 130 | 170 | 200 |

| Elongation | 16-18% | 12-14% | 6-8% | 8-10% | 8-10% |

| Hardness | 25 | 50 | 65 | 75 | 80 |

6063A aluminum rod bar

| Mechanical Properties | O/H111 | T4 | T5 | T6 |

| Tensile strength Rm/Mpa | 150 | 150 | 200 | 230 |

| Yield strength Rp0.2/Mpa | - | 90 | 160 | 190 |

| Elongation | 14-16% | 10-12% | 5-7% | 5-7% |

| Hardness | 28 | 50 | 75 | 80 |

Extrusion performance of 6063 aluminum bar

6063 aluminum bar is widely recognized for its exceptional extrusion performance, making it one of the most frequently used alloys in the production of precision-shaped bars and profiles. It has a favorable combination of strength, surface quality, and ease of forming.

- Typical extrusion temperature: 480–520 °C

- Common temper for extruded bar: T5 / T6

Excellent Extrudability: With low deformation resistance and good plasticity, 6063 can be extruded into complex shapes at high speeds with consistent quality.

Smooth Surface Finish: Post-extrusion, the bars often have a clean and bright finish that reduces the need for extensive post-processing.

Stable Dimensions: The alloy maintains dimensional stability during extrusion, supporting precise tolerances for structural and decorative applications.

Optimized for Thin-Walled Structures: Suitable for long-length or lightweight applications where material efficiency is crucial.

Thanks to its balanced processing properties and surface appearance, 6063 aluminum bar is widely used in construction components, decorative profiles, railings, and machined parts.

Best applications of 6063 aluminum rod

6063 Aluminum Rod for Construction

6063 Aluminum Rod for Construction- With its excellent corrosion resistance, extrudability, and superior anodizing performance, 6063 aluminum rod is ideal for making complex building components such as curtain wall profiles, stair railings, and decorative architectural profiles.

6063 Aluminum Rod for Window and Door Frames

6063 Aluminum Rod for Window and Door Frames- Due to its superior extrudability, corrosion resistance, and attractive surface finish, 6063 aluminum rod can produce precise and durable window and door profiles, including door frames, window frames, tracks, and accessories.

6063 Aluminum Rod for Electrical Components and Conduits

6063 Aluminum Rod for Electrical Components and Conduits- Thanks to its excellent electrical conductivity, corrosion resistance, and heat dissipation, the 6063 aluminum rod provides reliable power transmission and cooling solutions. It is commonly used in busbars, bus pipes, and other extruded components in the electrical industry.

6063 Aluminum Rod for Irrigation System Pipes

6063 Aluminum Rod for Irrigation System Pipes- Due to its outstanding extrudability and corrosion resistance, the 6063 aluminum rod is an ideal choice for producing lightweight, durable irrigation pipes, ensuring the long-term reliability of modern agricultural irrigation systems, including sprinkler and drip irrigation tubes.

6063 Aluminum Rod for Heat Sinks

6063 Aluminum Rod for Heat Sinks- With its excellent extrudability and superb thermal conductivity, the 6063 aluminum rod is ideal for manufacturing highly efficient extruded aluminum heat sinks, significantly improving device cooling performance and extending service life.

6063 Aluminum Rod for Cylinder Tubes

6063 Aluminum Rod for Cylinder Tubes- With superior surface finish and corrosion resistance, the 6063 aluminum rod is perfect for pneumatic system cylinder tubes. Hard anodizing further enhances wear resistance, significantly improving the lifespan and reliability of the cylinders.

6063 Aluminum Rod for Ladders

6063 Aluminum Rod for Ladders- Thanks to its moderate strength, lightweight, corrosion resistance, and rust-proof characteristics, the 6063 aluminum rod is ideal for manufacturing aluminum ladders, ensuring durability and excellent load-bearing capacity over time.

6063 Aluminum Rod for Furniture

6063 Aluminum Rod for Furniture- With its excellent extrudability, corrosion resistance, and good surface finish, 6063 aluminum rod is perfect for manufacturing furniture and accessories, including cabinet handles, wardrobe handles, hinges, furniture corner guards, and decorative trims.

Mastar EN AW-6063 Aluminum Rod Size Chart

| 6063 Extruded Aluminum Bar Rod | ||

| 1/2" 6063 Aluminum EXT Bar | 1-5/8" 6063 Aluminum EXT Bar | 3-1/2" 6063 Aluminum EXT Bar |

| 9/16" 6063 Aluminum EXT Bar | 1-3/4" 6063 Aluminum EXT Bar | 3-5/8" 6063 Aluminum EXT Bar |

| 5/8" 6063 Aluminum EXT Bar | 1-7/8" 6063 Aluminum EXT Bar | 3-3/4" 6063 Aluminum EXT Bar |

| 11/16" 6063 Aluminum EXT Bar | 2" 6063 Aluminum EXT Bar | 4" 6063 Aluminum EXT Bar |

| 3/4" 6063 Aluminum EXT Bar | 2-1/8" 6063 Aluminum EXT Bar | 4-1/2" 6063 Aluminum EXT Bar |

| 13/16" 6063 Aluminum EXT Bar | 2-1/4" 6063 Aluminum EXT Bar | 5" 6063 Aluminum EXT Bar |

| 7/8" 6063 Aluminum EXT Bar | 2-3/8" 6063 Aluminum EXT Bar | 6" 6063 Aluminum EXT Bar |

| 15/16" 6063 Aluminum EXT Bar | 2-1/2" 6063 Aluminum EXT Bar | 7" 6063 Aluminum EXT Bar |

| 1" 6063 Aluminum EXT Bar | 2-5/8" 6063 Aluminum EXT Bar | 8" 6063 Aluminum EXT Bar |

| 1-1/8" 6063 Aluminum EXT Bar | 2-3/4" 6063 Aluminum EXT Bar | 10" 6063 Aluminum EXT Bar |

| 1-1/4" 6063 Aluminum EXT Bar | 3" 6063 Aluminum EXT Bar | 12" 6063 Aluminum EXT Bar |

| 1-5/16" 6063 Aluminum EXT Bar | 3-1/4" 6063 Aluminum EXT Bar | 14" 6063 Aluminum EXT Bar |

| 1-1/2" 6063 Aluminum EXT Bar | 3-3/8" 6063 Aluminum EXT Bar | 16" 6063 Aluminum EXT Bar |

| 6063 Aluminum Cold Finish Rod Bar | ||

| 1/2" 6063 Aluminum CF Rod | 1-1/2" 6063 Aluminum CF Rod | 3-1/4" 6063 Aluminum CF Rod |

| 9/16" 6063 Aluminum CF Rod | 1-5/8" 6063 Aluminum CF Rod | 3-3/8" 6063 Aluminum CF Rod |

| 5/8" 6063 Aluminum CF Rod | 1-3/4" 6063 Aluminum CF Rod | 3-1/2" 6063 Aluminum CF Rod |

| 11/16" 6063 Aluminum CF Rod | 1-7/8" 6063 Aluminum CF Rod | 3-5/8" 6063 Aluminum CF Rod |

| 3/4" 6063 Aluminum CF Rod | 2" 6063 Aluminum CF Rod | 3-3/4" 6063 Aluminum CF Rod |

| 13/16" 6063 Aluminum CF Rod | 2-1/8" 6063 Aluminum CF Rod | 4" 6063 Aluminum CF Rod |

| 7/8" 6063 Aluminum CF Rod | 2-1/4" 6063 Aluminum CF Rod | 4-1/2" 6063 Aluminum CF Rod |

| 15/16" 6063 Aluminum CF Rod | 2-3/8" 6063 Aluminum CF Rod | 5" 6063 Aluminum CF Rod |

| 1" 6063 Aluminum CF Rod | 2-1/2" 6063 Aluminum CF Rod | 5-1/2" 6063 Aluminum CF Rod |

| 1-1/8" 6063 Aluminum CF Rod | 2-5/8" 6063 Aluminum CF Rod | 6" 6063 Aluminum CF Rod |

| 1-1/4" 6063 Aluminum CF Rod | 2-3/4" 6063 Aluminum CF Rod | 7" 6063 Aluminum CF Rod |

| 1-5/16" 6063 Aluminum CF Rod | 3" 6063 Aluminum CF Rod | 8" 6063 Aluminum CF Rod |

6063 aluminum rod purchasing guide

1. Comprehensive Documentation and Reports

Mastar provides complete quality testing reports, including Raw Material Certificates, Laboratory Test Reports, Fumigation Certificates, Specification Guides, Commercial Invoices, and Warranty Statements. This ensures transparency and traceability of each batch's quality.

2. High-Quality Export Packaging

During international transportation, goods often pass through multiple channels before reaching their final destination. The quality of the packaging will directly determine if the goods suffer from rust, corrosion, scratches, deformation, or other damage during transit. Thus, high-quality packaging is crucial.

Mastar has years of experience in export packaging, providing safe and reliable packaging solutions to thousands of companies. By using high-quality materials like fumigation-treated wooden crates and wooden pallets, our damage rate is only one-third of the industry average.

3. Professional Loading Solutions

With an experienced logistics team, we offer flexible loading options, including 20ft/40ft containers or bulk carriers. Regardless of the size, shape, or specifications of your cargo, we can tailor optimized loading plans for you, helping you save an average of 15% in container space and reduce logistics costs.

6063 aluminum rod knowledge center

6063/6063A aluminum rod bar standards and specifications

- AMS 4156 - 6063 T6 Extrusion

- AMS-QQ-A-200/9 - Aluminum Alloy 6063, Extruded Bar, Rod, Tube, and Shapes

- EN 12020 - Aluminum and Aluminum Alloys - Extruded Precision Profiles

- EN 755 - Aluminum and Aluminum Alloys - Extruded Rod/Bar, Tube and Profiles

- EN 754 - Aluminum and Aluminum Alloys - Cold Drawn Rod/Bar, Tube and Profiles

- ASTM B221 - Aluminum and Aluminum-Alloy Extruded Bars, Rods, Wire, Profiles, and Tubes

6061 vs 6063

Compared with 6061 aluminum bar, 6063 offers better extrudability and surface finish, making it ideal for architectural and decorative profiles, while 6061 provides higher strength for structural and mechanical applications. For details, visit our 6061 aluminum bar page.

6063-T5 vs 6063-T6

Strength: 6063-T6 has higher tensile strength compared to 6063-T5, making it more suitable for applications with higher strength requirements; while 6063-T5 is ideal for less demanding structural uses such as window and door profiles or decorative elements.

Formability: 6063-T5 offers better formability, making it suitable for complex extruded shapes, whereas 6063-T6 has slightly reduced formability due to its higher strength.

Hardness: 6063-T6 is cooled by water and then artificially aged, resulting in higher hardness. 6063-T5 is air-cooled and artificially aged, leading to a slightly lower hardness level.

Applications: 6063-T6 is commonly used in the main structural components of curtain walls, while 6063-T5 is widely applied in light structures and decorative applications.

6063-T52 vs 6061-T6

Strength: 6061-T6 offers significantly higher tensile strength than 6063-T52, making it suitable for heavy-load and structural applications. 6063-T52 is more suited for lightweight construction and decorative uses.

Formability: 6063-T52 has better formability and is ideal for complex extruded shapes. In contrast, 6061-T6 has lower formability under high-strength conditions.

Machinability: 6061-T6 has superior machinability compared to 6063-T52, making it advantageous for scenarios requiring precision operations.

Weldability: Both have good weldability, but 6061-T6 combines strength and weldability, making it a better choice for high-strength welding applications.

6060-T66 vs 6063-T5

Strength: 6060-T66 has higher tensile and yield strength, with increases of 29% and 22.7% respectively, making it suitable for high-strength structural applications, while 6063-T5 is more commonly used in regular building structures like doors and windows.

Hardness: The hardness of 6060-T66 is 7.6% higher than that of 6063-T5, allowing it to resist deformation and damage more effectively, especially in extreme weather conditions.

Toughness: 6060-T66 has an elongation after fracture of 13%, providing better deformation resistance and reducing the risk of catastrophic breakage. 6063-T5, on the other hand, excels in formability and standard structural uses.

Application Fields: 6060-T66 is primarily used in narrow frame doors and windows requiring high strength and durability, while 6063-T5 is widely found in general window and door frames, focusing on thermal insulation and ease of processing.