6008 aluminum alloy (AlSiMgV, A96008) is a high-performance material known for its outstanding strength, corrosion resistance, and excellent machinability.

It is widely used in industries such as automotive, aerospace, and structural engineering, making it a key material in modern manufacturing.

Specifications of 6008 aluminum bars

- EN 755

- EN 573

- ASTM B 221

- IATF16949

Popular products of 6008 aluminum bars

6008 Aluminum Round Bars

6008 Aluminum Round Bars- Diameter: Φ10mm - Φ200mm

- Length: 1m - 6m

6008 Aluminum Square Bars

6008 Aluminum Square Bars- Side length: 10mm - 200mm

- Length: 1m - 6m

6008 Aluminum Flat Bars

6008 Aluminum Flat Bars- Width: 10mm - 200mm

- Height: 5mm - 100mm

- Length: 1m - 6m

6008 Aluminum Hexagonal Bars

6008 Aluminum Hexagonal Bars- Side length: 10mm - 100mm

- Length: 1m - 6m

6008 forged bars vs 6008 extruded bars

We supply both 6008 forged bars and 6008 extruded bars to meet different strength and production requirements, offering flexible options to suit various applications. Quick Quote

- High-temperature forging

- Higher strength

- Suitable for high-load and high-pressure applications

- Lower cost

- High production efficiency

- Suitable for mass production and standard applications

Chemical elements of 6008 aluminum bars (EN 573-3)

| Chemical Element | % Present |

| Si | 0.50 - 0.90 |

| Fe | 0.35 max |

| Cu | 0.30 max |

| Mn | 0.30 max |

| Mg | 0.40 - 0.7 |

| Cr | 0.30 max |

| Zn | 0.20 max |

| Ti | 0.10 max |

| V | 0.05 - 0.20 |

| Other (Each) | 0.05 max |

| Others (Total) | 0.15 max |

| Aluminium (Al) | Remainder |

Physical properties of 6008 aluminum bars

| Physical Property | Value |

| Density | 2.70 g/cm³ |

| Melting Point | 640 °C |

| Thermal Expansion | 23 x10^-6 /K |

| Modulus of Elasticity | 69 GPa |

| Shear Modulus | 26 GPa |

| Thermal Conductivity | 192 W/m.K |

| Electrical Resistivity | 49 % IACS |

Mechanical properties of 6008 aluminum bars

| Temper | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Hardness (HB) |

| T4 | Min. 180 | Min. 90 | 15 | 50 |

| T6 | 250-270 | 200-225 | 8 | 85-90 |

Advantages of 6008 aluminum bars

- High Strength: With high tensile and yield strength, it is ideal for components that need to withstand heavy loads.

- Lightweight: The lighter weight of the aluminum alloy helps reduce the overall weight of vehicles, improving fuel efficiency.

- Corrosion Resistance: Excellent corrosion resistance extends its service life in harsh environments.

- Good Machinability: Suitable for precision machining to meet high accuracy requirements.

Applications of 6008 aluminum bars

- Automotive Industry: Used for manufacturing bumper beams, covers, doors, window frames, roofs, floors, and other components, offering excellent strength and corrosion resistance, ideal for lightweight designs.

- Aerospace: Applied in aircraft parts and spacecraft structures, providing high strength and good weather resistance.

- Construction Machinery: Used for manufacturing structural components and parts that endure high-strength loads and exhibit good corrosion resistance.

- Construction Industry: Used in building frames and decorative materials, meeting both strength and aesthetic requirements.

- Shipbuilding Industry: Suitable for the manufacturing of hulls and ship components, able to withstand corrosion in harsh marine environments.

- Industrial Equipment: Widely used in the manufacturing of industrial equipment and tools, especially in fields requiring lightweight, high-strength, and corrosion-resistant materials.

Suppliers of 6008 aluminum bars: we offer the following value-added services

- Custom Services: Provide customized options for different sizes, surface treatments, machining methods, etc., according to customer requirements.

- Fast Delivery: Sufficient stock of standard sizes and specifications to ensure quick shipping.

- Competitive Pricing: We offer competitive prices and provide discounts for large volume orders.

- After-Sales Support: Comprehensive after-sales service to ensure customers' peace of mind during product use.

Comprehensive quality inspection reports for 6008 aluminum bars

- Ultrasonic Testing: Ensures no internal defects.

- Chemical Composition Analysis: Conforms to industry standards.

- Mechanical Property Testing: Verifies product strength.

- Non-Destructive Testing: Comprehensive inspection to detect potential issues.

- Appearance Inspection: Strict quality control for visual perfection.

- Traceability Records: Full traceability throughout the process.

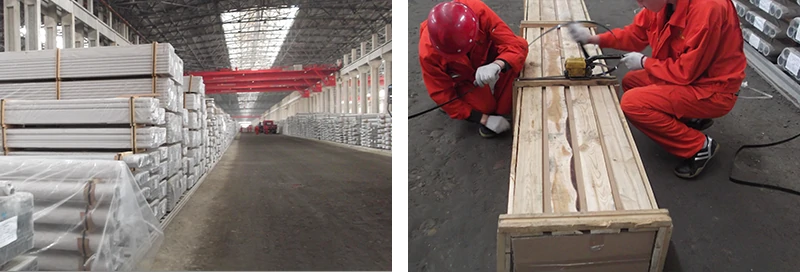

Packaging and shipping of 6008 aluminum bars

We provide professional packaging and shipping services for 6008 aluminum bars to ensure the products arrive safely and undamaged.

We use high-quality packaging materials such as fumigated wooden boxes and pallets to prevent moisture, corrosion, or damage during transit.

Based on customer needs, we offer flexible shipping methods including sea, air, and land transportation. We also tailor container loading plans to maximize space utilization and reduce logistics costs based on the size and weight of the shipment.

Whether for small or large orders, we ensure timely delivery to meet your project requirements.

Comparison between 6008 aluminum and 6061 aluminum

6008 aluminum alloy has many similarities to 6061 aluminum alloy, but it outperforms 6061 in some applications:

Tensile Strength: 6008 aluminum reaches up to 270 MPa in the T6 state, whereas 6061 has lower tensile strength.

Corrosion Resistance: 6008 aluminum has slightly better corrosion resistance than 6061, particularly in demanding environments like the automotive industry.