2A50 aluminum alloy rod is a type of hard aluminum alloy, also known as a 6.5% Cu-Al-Mg series forged aluminum alloy. The 2A50 aluminum alloy features good thermoplasticity, machinability, low electrical resistivity, and excellent performance in welding and arc welding. Additionally, it has high strength and good corrosion resistance, making it suitable for the manufacturing and strengthening of various parts.

Mastar has a robust inventory system that offers a variety of sizes of 2A50 aluminum rods. It also supports custom cutting and various surface treatments to meet the diverse needs of customers.

Stock sizes of 2A50 aluminum bar

Below are the popular sizes of 2A50 aluminum bars in Mastar's inventory. If you don't find the size that matches your needs, please contact us, and we will leverage our extensive inventory to provide you with a solution.

| Product | Temper | OD(mm) | Length(mm) |

| 2A50 Aluminum bar | H112 | φ250mm | 2600mm |

| 2A50 Aluminum bar | H112 | φ260mm | 6000mm |

| 2A50 Aluminum bar | T1 | φ65mm | 6000mm |

| 2A50 Aluminum bar | T1 | φ85mm | 4000mm |

| 2A50 Aluminum bar | T1 | φ85mm | 6000mm |

| 2A50 Aluminum bar | T1 | φ100mm | 4200mm |

| 2A50 Aluminum bar | T1 | φ110mm | 6000mm |

| 2A50 Aluminum bar | T1 | φ130mm | 6000mm |

| 2A50 Aluminum bar | T1 | φ140mm | 6000mm |

| 2A50 Aluminum bar | T1 | φ170mm | 6000mm |

| 2A50 Aluminum bar | T1 | φ190mm | 6000mm |

| 2A50 Aluminum bar | T1 | φ220mm | 6000mm |

| 2A50 Aluminum bar | T1 | φ230mm | 6000mm |

| 2A50 Aluminum bar | T1 | φ270mm | 6000mm |

| 2A50 Aluminum bar | T1 | φ280mm | 2100mm |

| 2A50 Aluminum bar | T1 | φ280mm | 6000mm |

| 2A50 Aluminum bar | T1 | φ290mm | 6000mm |

| 2A50 Aluminum bar | T1 | φ300mm | 4200mm |

| 2A50 Aluminum bar | T1 | φ300mm | 6000mm |

| 2A50 Aluminum bar | T1 | φ320mm | 6000mm |

| 2A50 Aluminum bar | T1 | φ330mm | 3400mm |

| 2A50 Aluminum bar | T1 | φ330mm | 6000mm |

| 2A50 Aluminum bar | T1 | φ350mm | 6000mm |

| 2A50 Aluminum bar | T6 | φ20mm | 6000mm |

| 2A50 Aluminum bar | T6 | φ30mm | 2800mm |

| 2A50 Aluminum bar | T6 | φ30mm | 3000mm |

| 2A50 Aluminum bar | T6 | φ30mm | 3200mm |

| 2A50 Aluminum bar | T6 | φ40mm | 3400mm |

| 2A50 Aluminum bar | T6 | φ50mm | 6000mm |

| 2A50 Aluminum bar | T6 | φ60mm | 6000mm |

| 2A50 Aluminum bar | T6 | φ70mm | 3600mm |

| 2A50 Aluminum bar | T6 | φ80mm | 3900mm |

| 2A50 Aluminum bar | T6 | φ85mm | 5000mm |

| 2A50 Aluminum bar | T6 | φ90mm | 6000mm |

| 2A50 Aluminum bar | T6 | φ100mm | 6000mm |

| 2A50 Aluminum bar | T6 | φ110mm | 4200mm |

| 2A50 Aluminum bar | T6 | φ110mm | 5000mm |

| 2A50 Aluminum bar | T6 | φ120mm | 5200mm |

| 2A50 Aluminum bar | T6 | φ130mm | 6000mm |

| 2A50 Aluminum bar | T6 | φ140mm | 6000mm |

| 2A50 Aluminum bar | T6 | φ150mm | 6000mm |

| 2A50 Aluminum bar | T6 | φ160mm | 5500mm |

| 2A50 Aluminum bar | T6 | φ160mm | 6000mm |

| 2A50 Aluminum bar | T6 | φ180mm | 6000mm |

| 2A50 Aluminum bar | T6 | φ190mm | 4100mm |

| 2A50 Aluminum bar | T6 | φ200mm | 3900mm |

| 2A50 Aluminum bar | T6 | φ200mm | 6000mm |

| 2A50 Aluminum bar | T6 | φ200mm | 3800mm |

| 2A50 Aluminum bar | T6 | φ210mm | 6000mm |

| 2A50 Aluminum bar | T6 | φ220mm | 6000mm |

| 2A50 Aluminum bar | T6 | φ230mm | 3000mm |

| 2A50 Aluminum bar | T6 | φ240mm | 6000mm |

Click to see all

Click to see all Characteristics of 2A50 aluminum bars

- High strength, comparable to hard aluminum during quenching and artificial aging, with good processability; however, it exhibits extrusion effects, resulting in significant differences in properties between longitudinal and transverse directions.

- Good corrosion resistance, but prone to intergranular corrosion.

- Excellent performance in contact welding and roll welding, but poor performance in arc welding and gas welding.

- Maintains good plasticity and low deformation resistance at high temperatures, making it easier to operate and control during hot processing.

- The 2A50 aluminum alloy has good machinability, suitable for drilling, turning, milling, and other machining operations.

- 2A50 aluminum alloy has a low resistivity, which gives it excellent characteristics for manufacturing components that require good electrical conductivity, such as resistors.

Applications of 2A50 aluminum bar

Mainly used for manufacturing forgings and stampings that require medium strength and complex shapes. Below are applications in different fields.

Aerospace

Aircraft Structural Components: Used to manufacture structural parts such as wing beams, fuselage frames, and landing gear. These components require high strength and good fatigue performance to withstand various loads during flight.

Aircraft Parts: Used to produce critical structural components of aircraft, such as engine mounts and fuselage connections.

Automotive Industry

Automobile Frames and Structural Components: Used in the manufacture of car frames, suspension systems, and other high-strength parts. The high strength of 2A50 aluminum alloy makes it suitable for load-bearing automotive applications.

High-Performance Cars and Racing: Used to manufacture components for racing cars and high-performance vehicles, reducing weight while increasing strength.

Military Applications

Military Equipment: Used in the production of various military equipment and devices, such as armored vehicles, weapon systems, and communication devices. The high strength and durability of 2A50 aluminum alloy make it suitable for various military applications.

Military Aircraft and Helicopters: Used in military aircraft to manufacture high-strength structural components, ensuring reliability under extreme conditions.

Chemical composition of 2A50 aluminum bar

| Elements | Composition(%) |

| Si | 0.7 – 1.2 |

| Cu | 1.8 – 2.6 |

| Mg | 0.40 – 0.8 |

| Zn | ≤ 0.30 |

| Mn | 0.40 – 0.8 |

| Ti | ≤ 0.15 |

| Ni | ≤ 0.10 |

| Fe | 0.000 – 0.700 |

| Al | Remainder |

| Other(each) | ≤ 0.05 |

| Other(total) | ≤ 0.10 |

Mechanical properties of 2A50 aluminum bar

| Alloy | Temper | OD(mm) | Tensile Strength(MPa) | Elongation (%) |

| 2A50 | T1, T6 | ≤150mm | ≥ 355 | ≥ 12% |

Heat treatment specifications for 2A50 aluminum bars

Homogenization annealing: Heat to 515–530°C; hold for 12–14 hours; furnace cool.

Full annealing: Heat to 380–450°C; depending on material thickness; cool to 300°C at a rate of 30–50°C/hour, then air cool.

Rapid annealing: Heat to 350–460°C; hold for 30–120 minutes; air cool.

Quenching and aging: Quench at 505–520°C, water cool; natural aging at room temperature for 96 hours.

Coarse grain issue at the ends of 2A50 aluminum bar

Why coarse grain rings occur?

During the later stages of extrusion of 2A50 aluminum bars, when the metal flowing towards the center of the product reaches or approaches the critical level of deformation, coarse grain ring structures form after quenching.

Process measures to reduce coarse grain rings in 2A50 aluminum bar

Optimization of alloying elements: Elements such as Mn, Fe, and Ti in 2A50 aluminum alloy can increase the recrystallization temperature and suppress grain growth. The second-phase particles formed by Mn are dispersed and effectively prevent grain coarsening. The presence of Mg and Si, which form Mg2Si compounds, also helps control grain size. During extrusion, the outer metal experiences a stress gradient due to friction, promoting the precipitation of Mn particles and lowering the recrystallization temperature, thereby reducing coarse grains at the surface.

Lubricated extrusion: Lubricated extrusion reduces friction between the metal and the inner wall of the extrusion die, decreasing the extent of grain fragmentation in the shear deformation zone and avoiding excessive grain growth. However, excessive or improper lubrication can leave oil residues on the surface, affecting product quality.

Appropriate extrusion speed: Lower extrusion speeds result in smaller and more uniform grains, reducing the likelihood of coarse grain rings. At high extrusion speeds, the friction between the metal and the die increases, leading to shear deformation and coarse grains.

Suitable extrusion temperature: At low temperatures, the surface deformation of the metal is insufficient to form coarse grains. At high temperatures, increased grain distortion energy facilitates recrystallization, which may lead to the formation of coarse grain rings.

Influence of extrusion die: An excessively long die reducing section increases the friction area between the surface metal and the die, causing surface metal flow to lag and exacerbating the formation of coarse grain rings. Optimizing the length of the reducing section can effectively reduce coarse grain structures.

Why choose Mastar?

Customized services: offering a variety of specifications and surface treatments to meet personalized customer needs.

Comprehensive certification: all products are certified to international standards such as iso and ce, ensuring reliable product quality.

Fast delivery: ample inventory allows for short delivery times, accommodating urgent order requirements.

Quick response: rapidly addressing customer inquiries and quotes, providing the most competitive prices.

Price updates: real-time updates on pricing based on international aluminum market prices, keeping customers informed of the latest prices.

Free samples: all samples are provided free of charge, allowing customers to test before placing orders.

Mastar 2A50 aluminum bar purchasing guide

Before purchasing 2A50 aluminum bars from Mastar, please confirm the sizes and quantities you need. Then, contact our customer service team, and we will provide you with the highest quality products at the most competitive market prices..

2A50 aluminum bar price

2A50 aluminum bar price: (LME ingot price + processing fee) × weight + packaging fee + shipping fee.

Please contact Mastar for pricing and the processing fee per ton for various specifications of aluminum bars. The processing fees for different sizes of 2A50 aluminum bars may vary significantly, and we will provide you with the best quotation.

2A50-T6 aluminum bar is the most commonly ordered condition.

2A50 aluminum bar appearance quality

- The surface of 2A50 round bars, square bars, and hex bars must be free from cracks, bubbles, and corrosion spots.

- The thickness of 2A50 round bars, square bars, and hex bars must not exceed the allowable deviation range.

- The surface of 2A50 round bars, square bars, or hex bars must not have deep scratches, wear, dents, or straightening marks that exceed the deviation range.

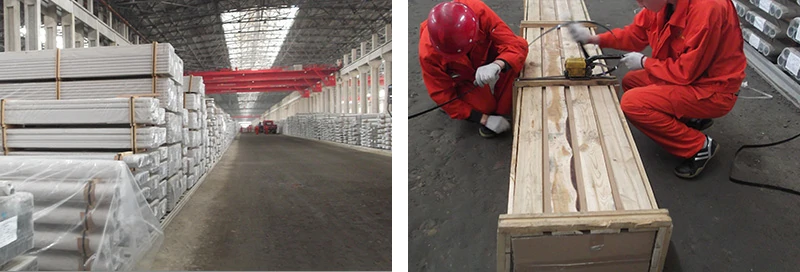

2A50 aluminum bar packaging

- Plastic or kraft paper packaging, including moisture-absorbing desiccants.

- Mounted on wooden pallets, secured with steel straps, and provided with a fumigation certificate.

- Complies with GB/T 3199 standards.

- Packaging can be customized according to other customer requirements.

Click to collapse

Click to collapse