Aluminum 2219 is a high-strength alloy that combines good machinability and mechanical properties.

It can be used in temperatures ranging from -452°F to 600°F and offers excellent fracture toughness, making it a premium metal for aerospace component manufacturing and high-temperature structural applications.

As a professional aluminum supplier, we offer 2219 aluminum forged bars, extruded bars, sheets, and more, available in your custom sizes and shapes.

Specifications of 2219 aluminum bar

- ASTM B211

- AMS 4162,AMS 4163,AMS 4066,AMS 4068

- ASTM B247

- ASTM B316

- QQ-A-367,QQ-A-430

- MIL-A-46118,MIL-A-46808,MIL-A-8920,MIL-A-22771

- SAE J454

Popular sizes of 2219 aluminum bar

Our 2219 aluminum bars meet or exceed the industry's most stringent standards, including all applicable AMS, ASTM, MIL, QQ, and SAE specifications.

2219 -T8511 Aerospace Aluminum Bar

2219 -T8511 Aerospace Aluminum Bar- Standards: AMS 4162

- Temper: T8511

- Diameter 0.10 - 10 inches

- Length: 118 inches (can be cut)

2219-T851 Aluminum Extruded Bar

2219-T851 Aluminum Extruded Bar- Standards: AMS B211

- Temper: T851

- Diameter 0.5 - 4 inches

- Length: 20 inches (can be cut)

2219-T6 Aluminum Forged Bar

2219-T6 Aluminum Forged Bar- Standards: ASTM B247

- Temper: T6

- Diameter: 0.02 - 4 inches

- Length: 20 inches (customizable)

In addition to 2219 aluminum bars, Mastar also supplies a wide range of aluminum bar alloys in various shapes such as round bars, square bars, flat bars, and hex bars. If you are looking for alternatives with similar machinability or mechanical strength, feel free to explore our whole aluminum bar product pages or contact us for assistance.Quick Quote

Chemical elements of 2219 aluminum bar

| Chemical Element | % Present |

| Si | 0.0 - 0.20 |

| Fe | 0.0 - 0.30 |

| Cu | 5.8 - 6.8 |

| Mn | 0.2 - 0.40 |

| Mg | 0.0 - 0.02 |

| Zn | 0.0 - 0.10 |

| Ti | 0.02 - 0.10 |

| V | 0.05 - 0.15 |

| Zx | 0.10 - 0.25 |

| Other (Each) | 0.0 - 0.05 |

| Others (Total) | 0.0 - 0.15 |

| Aluminium (Al) | Balance |

Physical properties of 2219 aluminum bar

| Physical Property | Value |

| Density | 2.70 g/cm³ |

| Melting Point | 640°C |

| Thermal Expansion | 22 x10^-6 /K |

| Modulus of Elasticity | 72 GPa |

| Thermal Conductivity | 120 W/m.K |

| Specific Heat Capacity | 870 J/kg-K |

| Electrical Resistivity | 30% IACS |

Mechanical properties of 2219 aluminum bar

| Material | Temper | Direction | Tensile Strength (ksi) | Yield Strength (ksi) | Elongation (%) |

| 2219 (AMS 4162) | T8511 | L | 58 | 42 | 6 |

| 2219 (AMS 4162) | T8511 | LT | 56 | 39 | 4 |

| 2219 (ASTM B211) | T851 | - | 58 | 40 | 4 |

| 2219 (ASTM B247) | T6 | - | 61 | 41 | 5 |

Advantages of 2219 aluminum bar

- Strong and Lightweight: Combines high strength with lightweight properties, making it suitable for applications requiring structural integrity.

- High-Temperature Strength: Maintains strength in high temperatures ranging from 452°F to 600°F.

- Good Weldability: Easy to weld, with a low tendency to develop surface cracks during the welding process.

- Excellent Fracture Toughness: Provides outstanding resistance to fracture, suitable for high-strength applications.

- Corrosion Resistance: Exceptional corrosion resistance extends the service life of the material.

Machinability recommendations for 2219 aluminum bar

- This alloy is not suitable for hot working.

- It is best suited for cold working and can be machined in the annealed condition.

- It is recommended to use oil-based lubricants in all machining operations.

- Hot working and welding can adversely affect the corrosion resistance of this alloy.

- Traditional machining processes such as drilling, milling, and turning can be used for machining.

Welding recommendations for 2219 aluminum bar

- Welding can affect the corrosion resistance of 2219 aluminum bars. Therefore, post-weld heat treatment should be performed to restore corrosion resistance.

- Exercise caution when using resistance welding and inert gas welding, as strain cracking may occur during cooling.

- It is recommended to use 2219 aluminum as the filler material for welding 2219 aluminum bars.

Applications of 2219 aluminum bar

- Spacecraft and Rockets: Used in space boosters, fuel tanks, and rocket engine casings due to its ability to withstand extreme high and low temperature environments while maintaining high strength.

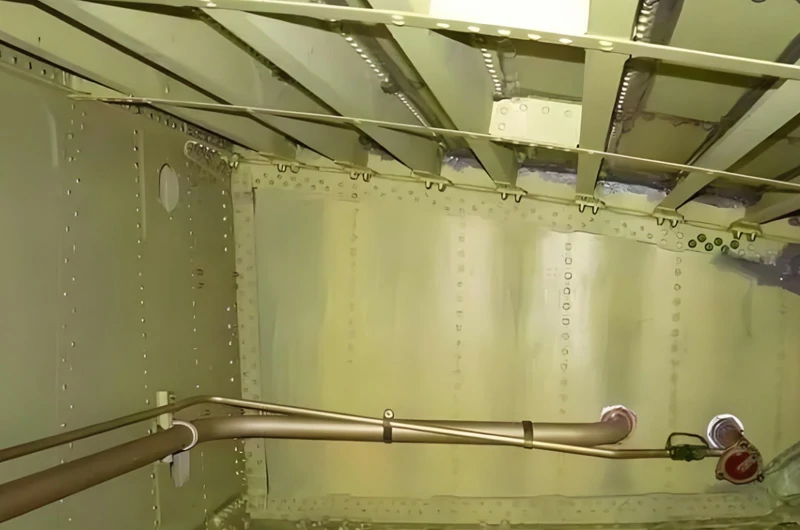

- Aerospace Structural Components: Widely used in the manufacture of critical structures for spacecraft and aircraft, such as fuselage frames, wing ribs, and engine parts.

- Automotive Components: Used in the manufacture of braking components and suspension systems due to its excellent strength-to-weight ratio and fatigue resistance.

Real-World applications of 2219 aluminum alloy

In the early Space Shuttle program, NASA utilized 2219 aluminum alloy to manufacture standard weight fuel tanks. This alloy was selected for its excellent high-temperature strength and low-temperature toughness, enabling it to perform in extreme environments.

2219 aluminum maintains its strength at very low temperatures while also being able to withstand extreme stresses encountered during flight and launch in high-temperature conditions.

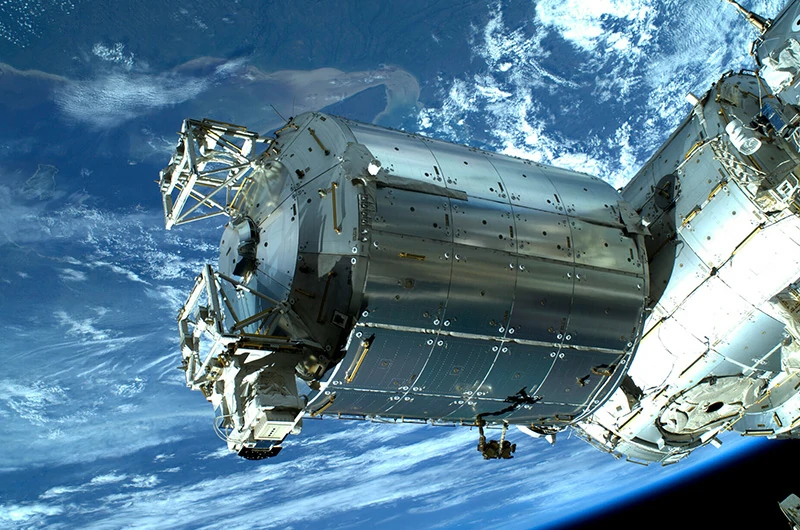

The Columbus module is an important scientific laboratory on the International Space Station (ISS), manufactured by the European Space Agency (ESA). This module is primarily used to support experiments and research in a microgravity environment.

To withstand the harsh conditions of low Earth orbit, the Columbus module is constructed using 2219 aluminum alloy.