5083 aluminum contains magnesium, along with small amounts of manganese and chromium. It is a high-strength, corrosion-resistant aluminum material that exhibits superior strength compared to 5052 aluminum plate, along with excellent ductility and good formability, making it particularly suitable for marine applications and the cryogenic market.

The 5083 alloy has strong corrosion resistance to seawater and industrial chemicals, retaining high strength even after welding. It is the highest strength among non-heat-treatable aluminum alloys, but its use is not recommended in environments exceeding 65°C. It is widely used in shipbuilding, cryogenic pressure vessels, body panels, and the manufacture of armored vehicles.

Click to view the 5083 Aluminum Plate Product Guide

Popular Products of 5083 aluminum plate

- 5083 O Aluminum Sheet Plate

Specifications: ASTM B209, EN 485, AMS 4056, AMS-QQ-A-250/6

5083 O in the annealed state ensures good ductility and is known for its excellent formability. It is widely used in tank car baffles, LNG storage tanks, and pressure vessels.

- 5083 H111 Aluminum Sheet Plate

Specifications: AMS-QQ-A-250/4, AMS 4035, ASTM B209

5083 H111 aluminum plate is in a state that has undergone solution treatment but not artificial aging. It offers good corrosion resistance and moderate strength while maintaining good formability during processing. It is widely used in tank heads, tank bodies, and truck fuel tanks/storage vessels.

- 5083 H116/H321 Aluminum Sheet Plate

Specifications: ASTM B928, EN 485, AMS-QQ-A-250/6

5083 H116/H321 aluminum plate is a high-strength aluminum alloy that has undergone solution treatment and artificial aging, ensuring higher strength, toughness, and corrosion resistance. It is widely used in shipbuilding and marine engineering.

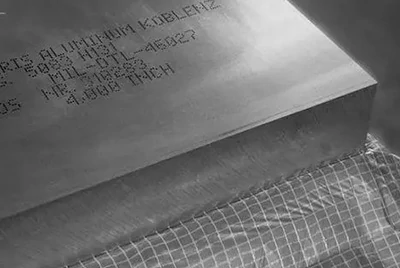

- 5083 H131 Aluminum Armor Plate

Specifications: MIL-DTL-46027

5083 H131 aluminum plate is a high-strength aluminum alloy designed for armor and protective applications, featuring excellent corrosion resistance and toughness. It is widely used in the military and security fields for armored vehicles and bullet-resistant structures.

- 5083 H32 Aluminum Sheet Plate

Specifications: ASTM B209, AMS-QQ-A-250/6

5083 H32 aluminum plate is an aluminum alloy that has undergone solution treatment and artificial aging, offering good strength and toughness. It is widely used in automotive body panels, fuel tanks, armored protection, and other structures requiring corrosion resistance.

- 5083 Aluminum Cast Plate

Thickness: 0.24"-15.75" (6mm-400mm)

Width: 52"-73.2" (1320mm-1860mm)

5083 cast plate generally offers better corrosion resistance than MIC6 and has superior anodizing reactions. It is commonly used in mold manufacturing, assembly fixtures, and vacuum suction cups.

- 5083 Aluminum Ultra Wide Plate

Width: 35.4"-104" (900mm-2650mm)

5083 aluminum ultra-wide plate is a high-strength, corrosion-resistant aluminum alloy plate designed for large structures and applications. It is widely used in ships, marine engineering, and heavy equipment, meeting the demands of high loads and extreme environments.

- 5083 Aluminum Thick Plate

Thickness: 2"-24" (50mm-600mm)

5083 aluminum thick plate is a high-strength aluminum alloy with excellent corrosion resistance and good formability. It is widely used in ship structures, mold manufacturing, and machining, especially suitable for applications in harsh environments.

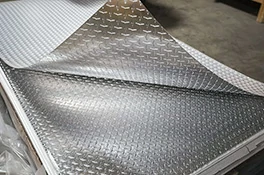

- 5083 Aluminum Tread Plate

Type: Diamond, 2 bar, 3 bar, 5 bar

5083 aluminum tread plate is an aluminum alloy material with excellent corrosion resistance and strength, widely used to create non-slip surfaces and enhance structural slip resistance. It is commonly used in ships, vehicles, construction, and other applications requiring non-slip features and increased strength, suitable for use in harsh environments.

What advantages do we have as a metal stock supplier?

Product traceability

Product traceability- Our entire material inventory features a unique spray code, ensuring comprehensive material traceability. This traceability is crucial for sectors such as oil and gas, aerospace, and defense.

Metal Guillotining Services

Metal Guillotining Services- We offer customers fast, high-precision shearing and thick plate sawing services that can be customized to the required dimensions for their projects. Our tolerances are very strict, allowing for significant savings in subsequent processing stages.

Typical application fields of 5083 aluminum sheet plate

5083 H116/H321 Marine Grade Aluminum Plate

5083 H116/H321 Marine Grade Aluminum Plate- Certification is available from classification societies such as CCS, BV, LR, ABS, KR, DNV, RINA, and PC.

- Ship Fuel Tanks

- Hull Outer Plates

- Bilge Decks

- Offshore Platforms

5083 O/H111 aluminum plate for tanker trucks

5083 O/H111 aluminum plate for tanker trucks- Tank Car Heads

- Tank Car Bodies

- Tank Car Baffles

5083 H311 armor aluminum plate

5083 H311 armor aluminum plate- Naval Vessels

- Tank Armor Plates

- Armored Personnel Carriers (APC)

5083 O Aluminum Sheet Plate for (Pressure Vessels)

5083 O Aluminum Sheet Plate for (Pressure Vessels)- Cryogenic Storage Tanks

- LNG Storage Tanks

- Pressure Vessels

Purchasing guide for 5083 aluminum sheet plate

Complete Documentation Reports

Mastar can provide you with detailed quality test reports, including raw material certificates, laboratory test reports, fumigation reports, specification guides, commercial invoices, and warranty certificates, ensuring that the quality of each batch of products is transparent and traceable.

Fine Export Packaging

In international shipping, goods must go through multiple channels to reach their final destination. The quality of packaging materials will directly determine whether goods rust, corrode, suffer scratches, deform, or sustain other damage during transit. Therefore, high-quality packaging materials are crucial.

Mastar has years of export packaging experience, providing safe and reliable packaging solutions for thousands of companies. By using high-quality packaging materials such as fumigated wooden boxes and wooden pallets, our packaging damage rate is only one-third of the industry average.

Specialized Loading Solutions

Our experienced tracking team can provide flexible and diverse loading solutions, with options for 20/40-foot containers or bulk carriers. Regardless of the size or shape of your cargo, we can tailor a detailed loading plan for you, potentially saving an average of 15% of container space and reducing your logistics costs.

Product guide for 5083 aluminum sheet plate

Equivalent grades of 5083 aluminum alloy

| UNS | EN | DIN | ISO | WNR | GOST | OLD |

| A95083 | ENAW-AlMg4.5Mn0.7 | AlMg4,5Mn | AlMg4.5Mn0.7 | 3.3547 | AMg4.5 | AG4,5MC |

Chemical composition of 5083 aluminum alloy

| Element | 5083(ASTM B-209) |

| Si | 0.4 |

| Fe | 0.4 |

| Cu | 0.1 |

| Mn | 0.4-1.0 |

| Mg | 4.0-4.9 |

| Cr | 0.05-0.25 |

| Zn | 0.25 |

| Ti | 0.15 |

| Others (Each) | 0.05 |

| Others (Total) | 0.15 |

| Al | Rem |

Physical properties of 5083 aluminum alloy

| Physical Property | Value |

| Density | 2.65 g/cm³ |

| Melting Point | 570°C |

| Thermal Expansion | 25 x10^-6 /K |

| Modulus of Elasticity | 72 GPa |

| Thermal Conductivity | 121 W/m.K |

| Electrical Resistivity | 0.058 x10^-6 Ω.m |

Mechanical properties of 5083 aluminum sheet plate (ASTM B209 & ASTM B928)

AlloyTemperSpecified Thickness (in.)Tensile Strength (ksi)Yield Strength (0.2% offset) (ksi)Elongation in 2 in. or 4×Diameter (min, %)Bend Diameter Factor, NProcess DescriptionProcess Description

| Alloy | Temper | Specified Thickness (in.) | Tensile Strength (ksi) | Yield Strength (0.2% offset) (ksi) | Elongation in 2 in. or 4×Diameter (min, %) | Bend Diameter Factor, N | Process Description | Process Description |

| 5083 | O | 0.051-1.500 | 40 | 51 | 18 | 29 | - | Annealed, soft state. |

| 5083 | O | 1.501-3.000 | 39 | 50 | 17 | 29 | - | |

| 5083 | O | 3.001-4.000 | 38 | - | 16 | 29 | - | |

| 5083 | O | 4.001-5.000 | 38 | - | 16 | 14 | - | |

| 5083 | O | 5.001-7.000 | 37 | - | 15 | 14 | - | |

| 5083 | O | 7.001-8.000 | 36 | - | 14 | 12 | - | |

| 5083 | H32 | 0.125-0.187 | 44 | 56 | 31 | - | 10 | Solution heat-treated and artificially aged, providing moderate strength and toughness. |

| 5083 | H32 | 0.188-1.500 | 44 | 56 | 31 | - | 12 | |

| 5083 | H32 | 1.501-3.000 | 41 | 56 | 29 | - | 12 | |

| 5083 | H112 | 0.250-1.500 | 40 | - | 18 | - | 12 | Solution heat-treated, but not artificially aged, with medium strength. |

| 5083 | H112 | 1.501-3.000 | 39 | - | 17 | - | 12 | |

| 5083 | H116 | 0.063-0.499 | 44 | 56 | 31 | - | 10 | Solution heat-treated and artificially aged, with higher strength and toughness. |

| 5083 | H116 | 0.500-1.250 | 44 | 56 | 31 | - | 12 | |

| 5083 | H116 | 1.251-1.500 | 44 | 56 | 31 | - | 12 | |

| 5083 | H116 | 1.501-3.000 | 41 | 56 | 29 | - | 12 | |

| 5083 | H321 | 0.125-0.187 | 44 | 56 | 31 | - | 10 | Solution heat-treated and artificially aged, with better corrosion resistance. |

| 5083 | H321 | 0.188-1.500 | 44 | 56 | 31 | - | 12 | |

| 5083 | H321 | 1.501-3.000 | 41 | 56 | 29 | - | 12 |

Standards and specifications for 5083 aluminum sheet plate

- AMS4056 - Aluminum Alloy, Sheet and Plate 4.4Mg - 0.70Mn - 0.15Cr (5083-0) Annealed

- AMS QQ-A-250/6 - Aluminum Alloy 5083, Plate and Sheet

- MIL-DTL-46027 - Armor Plate, Aluminum Alloy, Weldable 5083, 5456, & 5059

- ASTM B209 - Aluminum and Aluminum-Alloy Sheet and Plate

- ASTM B928 - High Magnesium Aluminum-Alloy Products for Marine Service and Similar Environments

- EN 485-2: 2008 Aluminum and aluminum alloys. Sheet, strip, and plate

What is the welding performance of 5083 aluminum alloy?

5083 aluminum alloy exhibits excellent weldability, and it is recommended to use 5183 filler metal during welding. Other suitable filler materials include 5356 and 5556. Outstanding welding results can be achieved using standard electrical and resistance welding methods, with GMAW (Gas Metal Arc Welding) and GTAW (Gas Tungsten Arc Welding) being the preferred welding processes. Gas welding is not recommended because the welding process can lead to a reduction in the strength of the heat-affected zone due to strain hardening and tempering.

Why is 5083 aluminum alloy suitable for marine environments?

5083 aluminum alloy performs exceptionally well in various atmospheric and saltwater environments, making it particularly suitable for marine applications. With a magnesium content exceeding 3.5%, it may be susceptible to stress corrosion cracking at temperatures below 65°C, thus limiting its application temperature. Additionally, the amount of cold working should be controlled to 1/4 hardness. Furthermore, 5083 has undergone specialized intergranular corrosion and exfoliation corrosion tests, confirming its suitability for marine vessel applications.