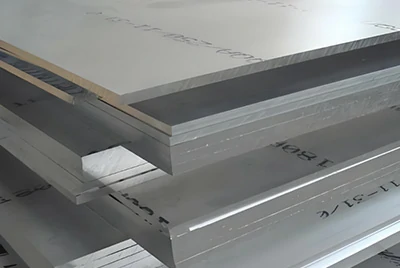

2024 Aluminum Plate is a high-strength aluminum alloy with copper as the primary alloying element. It boasts an excellent strength-to-weight ratio and good fatigue resistance, making it suitable for high-performance applications in the aerospace, automotive, and machinery sectors.

The common 2024-T3 temper is subjected to solution heat treatment and cold working, offering exceptional formability and high strength. Although it has lower corrosion resistance, its durability can be enhanced by surface cladding with pure aluminum (Alclad).

Click here to view the 2024 Aluminum Plate Product Guide

Popular products in 2024 aluminum plate

2024 O Bare Aluminum Sheet

Thickness: 0.016" - 0.25" (0.4 - 6.35 mm)

Specifications: AMS-QQ-A-250/4, AMS 4035, ASTM B209

2024-O aluminum is in an annealed state, having the lowest strength and highest ductility compared to other tempers of 2024 aluminum. It is commonly used in applications requiring high formability and good processing characteristics with relatively lower strength.

2024 O Alclad Aluminum Sheet

Thickness: 0.016" - 0.5" (0.4 - 12.7 mm)

Specifications: AMS-QQ-A-250/5, AMS 4040, ASTM B209

The 2024-O Alclad aluminum sheet is in an annealed state, with a surface layer of 1000 series pure aluminum to enhance corrosion resistance. It is primarily used for non-load-bearing aerospace components and pre-welding treatments, offering good ductility and workability.

2024 T3 Bare Aluminum Sheet

Thickness: 0.016" - 0.25" (0.4 - 6.35 mm)

Specifications: AMS-QQ-A-250/4, AMS 4037, ASTM B209

2024 T3 Bare aluminum sheet is the best-selling temper, subjected to solution heat treatment and cold working. It exhibits excellent formability and high strength, widely used in aircraft manufacturing due to its exceptional fatigue resistance.

2024 T3 Alclad Aluminum Sheet

Thickness: 0.016" - 0.25" (0.4 - 6.35 mm)

Specifications: AMS-QQ-A-250/4, AMS 4041, ASTM B209

The 2024 T3 Alclad aluminum sheet is a high-strength alloy that has undergone solution heat treatment and cold working, with a layer of 1000 series pure aluminum for enhanced corrosion resistance. Due to its excellent strength and fatigue resistance, this aluminum plate is widely used in aerospace structural components, and welding is generally not recommended.

2024 T351 Bare Aluminum Plate

Thickness: 0.25" - 8" (6.35 - 200 mm)

Specifications: AMS-QQ-A-250/4, AMS 4037, ASTM B209

The 2024 T351 Bare aluminum plate is typically subjected to solution heat treatment, cold working, and aging treatment, offering excellent strength and good fatigue resistance. It is widely used in aircraft cowling and structural components designed for high loads.

2024 T351 Alclad Aluminum Plate

Thickness: 0.25" - 8" (6.35 - 200 mm)

Specifications: AMS-QQ-A-250/5, AMS 4041, ASTM B209

The 2024 T351 Alclad aluminum plate is a high-strength aerospace aluminum alloy that has undergone solution heat treatment and aging treatment, with a layer of 1000 series pure aluminum for enhanced corrosion resistance. Its low residual stress and excellent resistance to explosive impacts make it widely used in aircraft skins, fuselage walls, and structural components.

2024 T42 Aluminum Plate

Thickness: 0.25"- 3"(6.35 - 76.2 mm)

Type: Bare, Alclad

Specifications: AMS-QQ-A-250/4, AMS-QQ-A-250/5

The 2024 T42 aluminum plate is typically subjected to solution heat treatment and natural aging. Unlike the T4 temper, T42 is generally completed by the recipient to ensure good strength and fatigue resistance, suitable for applications such as bulletproof plates and military aluminum plates, with a typical thickness of 5 mm. Under impact from a 25.4 mm spherical steel projectile, its ballistic limit velocity is 151.7 m/s, demonstrating good bulletproof performance.

2024 T861 Aluminum Sheet Plate

Thickness: 0.02"- 0.5" (0.5 - 12.7 mm)

Type: Bare, Alclad

Specifications: AMS 4193, AMS 4195, AMS-QQ-A-250/4, AMS-QQ-A-250/5

The 2024 T861 aluminum plate undergoes heat treatment and stretching processes, providing higher strength and better corrosion resistance, particularly suitable for the aerospace industry and high-load structural components.

2024 T652 Forged Aluminum Plate

Thickness: 8" - 18" (200 - 450 mm)

Specifications: ASTM B247

The 2024 T652 forged aluminum plate is used for aerospace applications, suitable for manufacturing aircraft aluminum plates, aluminum flanges, and custom aerospace forged aluminum parts. Its high strength and excellent fatigue resistance make it an ideal choice for high-performance structural components.

2024 F/H112 Aluminum Plate

Thickness: 0.25" - 8" (6.35 - 200 mm)

Specifications: GB/T 3880

The 2024 F/H112 aluminum plate refers to an aluminum alloy in the "fabricated state" or lightly cold-worked state without further heat treatment, offering good workability and medium strength. It is suitable for basic structural applications that do not require high mechanical performance.

What advantages do we have as metal stockists?

Product Traceability

Product Traceability- All of our material inventories come with unique spray codes to ensure comprehensive material traceability. This traceability is crucial for industries such as oil and gas, aerospace, and defense.

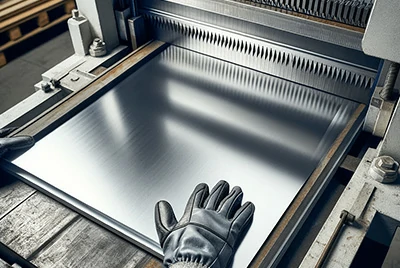

Metal Guillotining Services

Metal Guillotining Services- We offer our customers fast and high-precision shearing and thick plate sawing services, customizable to the dimensions required for their projects. With very strict tolerances, our services can significantly reduce the time needed for subsequent processing.

What are the ideal applications for the 2024 aluminum sheet plate?

2024 Aluminum Sheet Plate for Aerospace Applications

2024 Aluminum Sheet Plate for Aerospace Applications- Fuselage Structural Components

- Wing Surface Assemblies

- Bulkheads and Skins

- Engine Parts

2024 Aluminum Sheet Plate for Defense Applications

2024 Aluminum Sheet Plate for Defense Applications- Bulletproof Armor

- Weapon Systems

- Drone Frames

- Ship Structures

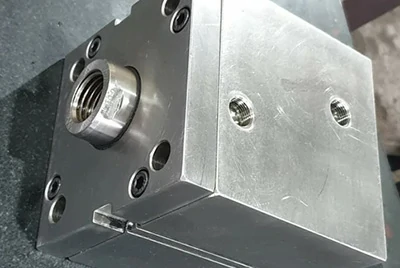

2024 Aluminum Sheet Plate for High-Stress Components

2024 Aluminum Sheet Plate for High-Stress Components- Hydraulic Cylinder and Gearbox Housings

- Structural Components for Construction Machinery

- Engine Support Structures

2024 Aluminum Sheet Plate for High-End Automobiles

2024 Aluminum Sheet Plate for High-End Automobiles- Body Structural Components

- Suspension System Parts

- Hoods

- Hubs and Wheels

Purchasing guide for 2024 aluminum sheet plate

1.Comprehensive Documentation

Mastar can provide you with detailed quality testing reports, including raw material certificates, laboratory test reports, fumigation reports, specification guides, commercial invoices, and guarantees, ensuring that the quality of each batch of products is transparent and traceable.

2. Quality Export Packaging

In international shipping, the goods must pass through multiple channels to reach their final destination. The quality of the packaging material directly determines whether the goods will rust, corrode, scratch, deform, or suffer other damages during transport. Therefore, high-quality packaging materials are crucial.

Mastar has years of export packaging experience and has provided safe and reliable packaging solutions to thousands of companies. By using high-quality packaging materials such as fumigated wooden boxes and wooden pallets, our packaging damage rate is only one-third of the industry average.

3. Specialized Loading Solutions

We have an experienced follow-up team that can provide flexible and diverse loading solutions. You can choose between 20/40-foot containers or bulk carriers. Regardless of the size or shape of your cargo, we can tailor a detailed loading plan for you, saving an average of 15% of container space and reducing your logistics costs.

Product guide for 2024 aluminum sheet plate

Equivalent designations for 2024 aluminum alloy

| UNS | EN | DIN | ISO | USA | WNR | GOST |

| A92024 | EN AW-2024 | AlCuMg2 | AlCu4Mg1 | AA2024 | 3.1355 | D16 |

Chemical composition of 2024 aluminum alloy

| Element | 2024(ASTM B-209) |

| Si | 0.5 |

| Fe | 0.5 |

| Cu | 3.8-4.9 |

| Mn | 0.3-0.9 |

| Mg | 1.2-1.8 |

| Cr | 0.1 |

| Zn | 0.25 |

| Ti | 0.15 |

| Others (Each) | 0.05 |

| Others (Total) | 0.15 |

| Al | Rem |

Chemical composition of 2024 aluminum alloy

| Physical Property | Value |

| Density | 2.78 g/cm³ |

| Melting Point | 502-638℃ |

| Thermal Expansion | 23 x10^-6 /K |

| Modulus of Elasticity | 70 GPa |

| Thermal Conductivity | 193 W/m.K |

| Electrical Resistivity | 3.49e-006 ohm-cm |

Mechanical properties of 2024 aluminum sheet plate (ASTM B209)

AlloyTemperSpecified Thickness (in.)Tensile Strength (ksi)Yield Strength (0.2% offset) (ksi)Elongation in 2 in. or 4×Diameter (min, %)Bend Diameter Factor, NProcess Description

| Alloy | Temper | Specified Thickness (in.) | Tensile Strength (ksi) | Yield Strength (0.2% offset) (ksi) | Elongation in 2 in. or 4×Diameter (min, %) | Bend Diameter Factor, N | Process Description |

| 2024 | O | 0.010-0.032 | 32 | 14 | 12 | 0 | Soft |

| 2024 | O | 0.033-0.063 | 32 | 14 | 12 | 1 | |

| 2024 | O | 0.064-0.128 | 32 | 14 | 12 | 4 | |

| 2024 | O | 0.129-0.499 | 32 | 14 | 12 | 6 | |

| 2024 | T3 | 0.008-0.009 | 63 | 42 | 10 | 4 | Solution heat treated, cold worked and naturally aged |

| 2024 | T3 | 0.010-0.020 | 63 | 42 | 12 | 4 | |

| 2024 | T3 | 0.021-0.051 | 63 | 42 | 15 | 5 | |

| 2024 | T3 | 0.052-0.128 | 63 | 42 | 15 | 6 | |

| 2024 | T3 | 0.129-0.249 | 64 | 42 | 15 | 8 | |

| 2024 | T351 | 0.250-0.499 | 64 | 42 | 12 | - | Solution heat treated then stress relieved by stretching. Equivalent to T4 condition. |

| 2024 | T351 | 0.500-1.000 | 63 | 42 | 8 | - | |

| 2024 | T351 | 1.001-1.500 | 62 | 42 | 7 | - | |

| 2024 | T351 | 1.501-2.000 | 62 | 42 | 6 | - | |

| 2024 | T351 | 2.001-3.000 | 60 | 42 | 4 | - | |

| 2024 | T351 | 3.001-4.000 | 57 | 41 | 4 | - | |

| 2024 | T4 | 0.010-0.020 | 62 | 40 | 12 | 4 | Solution heat treated and naturally aged to a substantially stable condition |

| 2024 | T4 | 0.021-0.051 | 62 | 40 | 15 | 5 | |

| 2024 | T4 | 0.052-0.128 | 62 | 40 | 15 | 6 | |

| 2024 | T4 | 0.129-0.249 | 62 | 40 | 15 | 8 | |

| 2024 | T42 | 0.010-0.020 | 62 | 38 | 12 | 4 | Solution heat treated and naturally aged to a substantially stable condition |

| 2024 | T42 | 0.021-0.051 | 62 | 38 | 15 | 5 | |

| 2024 | T42 | 0.052-0.128 | 62 | 38 | 15 | 6 | |

| 2024 | T42 | 0.129-0.249 | 62 | 38 | 15 | 8 | |

| 2024 | T42 | 0.250-0.499 | 62 | 38 | 12 | 10 | |

| 2024 | T42 | 0.500-1.000 | 61 | 38 | 8 | - | |

| 2024 | T42 | 1.001-1.500 | 60 | 38 | 7 | - | |

| 2024 | T42 | 1.501-2.000 | 60 | 38 | 6 | - | |

| 2024 | T42 | 2.001-3.000 | 58 | 38 | 4 | - | |

| 2024 | T62 | 0.010-0.499 | 64 | 50 | 5 | - | Solution heat treated then artificially aged by the user |

| 2024 | T62 | 0.500-3.000 | 63 | 50 | 5 | - | |

| 2024 | T72 | 0.010-0.249 | 60 | 46 | 5 | - | solution heat treated then specially artificially aged for resistance to stress corrosion |

| 2024 | T81 | 0.010-0.249 | 67 | 58 | 5 | - | Solution heat treated, cold worked then artificially aged |

| 2024 | T851 | 0.250-0.499 | 67 | 58 | 5 | - | Solution heat treated then stress relieved by stretching then artificially aged. |

| 2024 | T851 | 0.500-1.000 | 66 | 58 | 5 | - | |

| 2024 | T851 | 1.001-1.499 | 66 | 57 | 5 | - | |

| 2024 | T861 | 0.020-0.062 | 70 | 62 | 3 | - | solution heat treated, cold worked, and naturally aged. |

| 2024 | T861 | 0.063-0.249 | 71 | 66 | 4 | - | |

| 2024 | T861 | 0.250-0.499 | 70 | 64 | 4 | - | |

| 2024 | T861 | 0.5 | 70 | 64 | 4 | - |

Mechanical properties of alclad 2024 aluminum sheet plate (ASTM B209)

| Alloy | Temper | Specified Thickness (in.) | Tensile Strength (ksi) | Yield Strength (ksi) | Elongation in 2 in. or 4× Diameter, min (%) | Bend Diameter Factor (N) | Process Description |

| Alclad 2024 | O | 0.008-0.009 | 30 | 14 | 10 | 0 | Soft |

| Alclad 2024 | O | 0.010-0.032 | 30 | 14 | 12 | 0 | |

| Alclad 2024 | O | 0.033-0.062 | 30 | 14 | 12 | 1 | |

| Alclad 2024 | O | 0.063-0.249 | 32 | 14 | 12 | 2 | |

| Alclad 2024 | O | 0.250-0.499 | 32 | 14 | 12 | 3 | |

| Alclad 2024 | O | 0.500-1.750 | 32 | - | 12 | - | |

| Alclad 2024 | T3 | 0.008-0.009 | 58 | 39 | 10 | 4 | Solution heat treated, cold worked and naturally aged |

| Alclad 2024 | T3 | 0.010-0.020 | 59 | 39 | 12 | 4 | |

| Alclad 2024 | T3 | 0.021-0.040 | 59 | 39 | 15 | 4 | |

| Alclad 2024 | T3 | 0.041-0.062 | 59 | 39 | 15 | 5 | |

| Alclad 2024 | T3 | 0.063-0.128 | 61 | 40 | 15 | 5 | |

| Alclad 2024 | T3 | 0.129-0.249 | 62 | 40 | 15 | 8 | |

| Alclad 2024 | T351 | 0.250-0.499 | 62 | 40 | 12 | - | Solution heat treated then stress relieved by stretching. Equivalent to T4 condition. |

| Alclad 2024 | T351 | 0.500-1.000 | 63 | 42 | 8 | - | |

| Alclad 2024 | T351 | 1.001-1.500 | 62 | 42 | 7 | - | |

| Alclad 2024 | T351 | 1.501-2.000 | 62 | 42 | 6 | - | |

| Alclad 2024 | T351 | 2.001-3.000 | 60 | 42 | 4 | - | |

| Alclad 2024 | T351 | 3.001-4.000 | 57 | 41 | 4 | - | |

| Alclad 2024 | T4 | 0.010-0.020 | 58 | 36 | 12 | 4 | solution heat treated and naturally aged to a substantially stable condition |

| Alclad 2024 | T4 | 0.021-0.040 | 58 | 36 | 15 | 4 | |

| Alclad 2024 | T4 | 0.041-0.062 | 58 | 36 | 15 | 5 | |

| Alclad 2024 | T4 | 0.063-0.128 | 61 | 38 | 15 | 5 | |

| Alclad 2024 | T42 | 0.008-0.009 | 55 | 34 | 10 | 4 | Solution heat treated and naturally aged to a substantially stable condition |

| Alclad 2024 | T42 | 0.010-0.020 | 57 | 34 | 12 | 4 | |

| Alclad 2024 | T42 | 0.021-0.040 | 57 | 34 | 15 | 4 | |

| Alclad 2024 | T42 | 0.041-0.062 | 57 | 34 | 15 | 5 | |

| Alclad 2024 | T42 | 0.063-0.128 | 60 | 36 | 15 | 5 | |

| Alclad 2024 | T42 | 0.129-0.187 | 60 | 36 | 15 | 8 | |

| Alclad 2024 | T42 | 0.188-0.249 | 60 | 36 | 15 | 8 | |

| Alclad 2024 | T42 | 0.250-0.499 | 60 | 36 | 12 | 10 | |

| Alclad 2024 | T42 | 0.500-1.000 | 61 | 38 | 8 | - | |

| Alclad 2024 | T42 | 1.001-1.500 | 60 | 38 | 7 | - | |

| Alclad 2024 | T42 | 1.501-2.000 | 60 | 38 | 6 | - | |

| Alclad 2024 | T42 | 2.001-3.000 | 58 | 38 | 4 | - | |

| Alclad 2024 | T62 | 0.010-0.062 | 60 | 47 | 5 | - | Solution heat treated then artificially aged by the user |

| Alclad 2024 | T62 | 0.063-0.499 | 62 | 49 | 5 | - | |

| Alclad 2024 | T72 | 0.010-0.062 | 56 | 43 | 5 | - | solution heat treated then specially artificially aged for resistance to stress corrosion |

| Alclad 2024 | T72 | 0.063-0.249 | 58 | 45 | 5 | - | |

| Alclad 2024 | T81 | 0.010-0.062 | 62 | 54 | 5 | - | Solution heat treated, cold worked then artificially aged |

| Alclad 2024 | T81 | 0.063-0.249 | 65 | 56 | 5 | - | |

| Alclad 2024 | T851 | 0.250-0.499 | 65 | 56 | 5 | - | Solution heat treated then stress relieved by stretching then artificially aged. |

| Alclad 2024 | T851 | 0.500-1.000 | 66 | 58 | 5 | - | |

| Alclad 2024 | T861 | 0.020-0.062 | 64 | 58 | 3 | - | solution heat treated, cold worked, and naturally aged. |

| Alclad 2024 | T861 | 0.063-0.187 | 69 | 64 | 4 | - | |

| Alclad 2024 | T861 | 0.187-0.249 | 69 | 64 | 4 | - | |

| Alclad 2024 | T861 | 0.250-0.499 | 68 | 62 | 4 | - | |

| Alclad 2024 | T861 | 0.5 | 70 | 64 | 4 | - |

Standards and specifications for 2024 aluminum sheet plate

- AMS QQ-A-250/4 - Aluminum Alloy 2024, Plate and Sheet

- AMS QQ-A-250/5 - Aluminum Alloy Alclad 2024, Plate and Sheet

- AMS4035 - Aluminum Alloy, Sheet and Plate 4.4Cu - 1.5Mg - 0.60Mn (2024-O) Annealed; or when specified, "As Fabricated" (2024-F)

- AMS 4036 - Aluminum Alloy Sheet and Plate, Alclad One Side 4.4Cu - 1.5Mg - 0.60Mn Alclad One Side 2024 and 1-1/2% Alclad One Side 2024-T3 Sheet; 1-1/2% Alclad One Side 2024-T351 Plate

- AMS 4037 - Aluminum Alloy, Sheet and Plate 4.4Cu - 1.5Mg - 0.60Mn (2024; -T3 Flat Sheet, -T351 Plate) Solution Heat Treated

- AMS 4040 - Aluminum Alloy, Sheet and Plate, Alclad 4.4Cu - 1.5Mg - 0.60Mn (2024-O with 1-1/2% Alclad); Annealed

- AMS 4041 - Aluminum Alloy, Sheet and Plate, Alclad 4.4Cu - 1.5Mg - 0.60Mn (2024, -T3 Sheet/-T351 Plate with 1-1/2% Alclad) Solution Heat Treated, Cold Worked and Naturally Aged

- AMS 4077 - Aluminum Alloy Sheet and Plate, Alclad One Side 4.4Cu - 1.5Mg - 0.60Mn (Clad One Side 2024-O) Annealed

- AMS 4193 - Aluminum Alloy, Sheet, and Plate 4.4Cu - 1.5Mg - 0.60Mn (2024-T861) Solution Heat Treated, Cold Worked, and Precipitation Heat Treated

- AMS 4194 - Aluminum Alloy, Sheet and Plate, Alclad 4.4Cu - 1.5Mg - 0.60Mn (2024 -T361 Sheet/Plate with 1½% Alclad) Solution Heat Treated, 6% Cold Worked and Naturally Aged

- AMS 4195 - Aluminum Alloy Sheet and Plate, Alclad 4.4Cu - 1.5Mg - 0.60Mn (Alclad 2024 and 1-1/2% Alclad 2024-T861 Flat Sheet; 1-1/2% Alclad 2024-T861 Plate) Solution Heat Treated, Cold Worked, and Precipitation Heat Treated

- EN 485-2: 2008 Aluminum and aluminum alloys. Sheet, strip, and plate

- ASTM B209 - Aluminum and Aluminum-Alloy Sheet and Plate

Why is 2024 known as "aircraft aluminum"?

2024 aluminum alloy is referred to as "aircraft aluminum" due to its high strength-to-weight ratio, excellent fatigue resistance, and crack resistance, making it particularly suitable for the manufacturing of aerospace structural components. Its mechanical properties can be further enhanced through cold working and heat treatment, leading to widespread applications in critical areas of aircraft, such as fuselage, wing spars, and fasteners.

Although its corrosion resistance is somewhat lower, surface treatments can effectively enhance its durability. With its outstanding performance and a long history of application, 2024 aluminum alloy has become one of the standard materials in the aerospace industry.