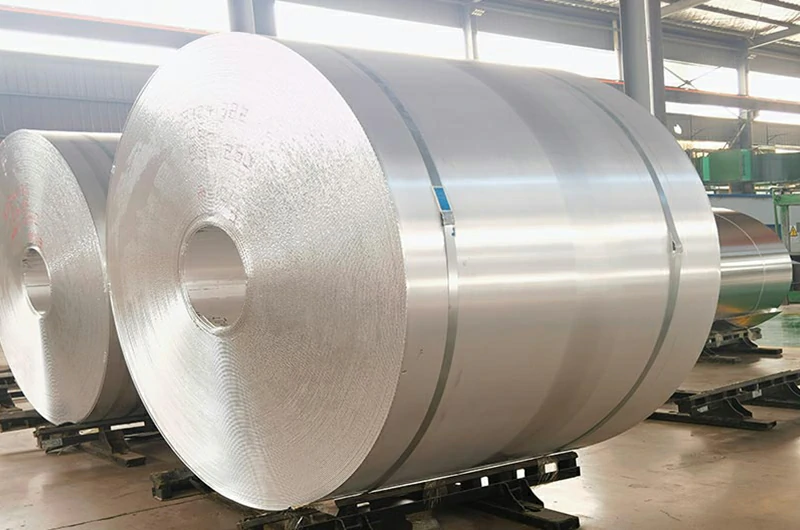

Aluminum coil is a rolled product made from high-quality aluminum alloy, known for its lightweight, durability, and excellent corrosion resistance. It is produced through hot rolling or cold rolling and is typically supplied in continuous coil form for easy handling and processing.

With a wide range of alloy types, tempers, and sizes, aluminum coil is widely used in the construction, automotive, HVAC, and packaging industries. Its outstanding strength, formability, and corrosion resistance make it an ideal choice for roofing panels, vehicle body components, duct systems, and food containers, offering both performance and versatility..

Introduction of aluminum coil

Thickness range: thin aluminum coil (0.2–1.0mm), medium-thick aluminum coil (1.0–3.0mm), thick aluminum coil (3.0–6.0mm)

Width range: narrow aluminum coil (20–600mm), regular aluminum coil (600–1600mm), extra-wide aluminum coil (1600–2680mm)

Alloy series: 1050 | 1060 | 1100 | 3003 | 3105 | 5005 | 5052 | 5754 | 6061 | 6063 | 8011

Types: embossed aluminum coil, color-coated aluminum coil, mirror aluminum coil, film-coated aluminum coil

Applications: aluminum coil for building curtain walls, roofing systems, aluminum composite panels, automotive heat insulation, packaging, and thermal insulation

Surface treatment: mill finish, anodized, color coating (PVDF, PE), mirror finish, embossed, film-coated

Temper: O, H14, H16, H18, H24, T4, T6

Specification: ASTM B209, EN 485, GB/T 3880, JIS H4000, ISO 6361

Certifications: ISO 9001:2015, RoHS, REACH, DNV, SGS, BV, ABS

Mastar: your trusted partner in aluminum coil

Mastar is an industry-leading aluminum coil supplier committed to delivering stable, high-quality, and customizable aluminum coil solutions to customers worldwide. We have earned wide recognition and a strong reputation across industries such as construction, packaging, automotive, electronics, and HVAC.

Our product range includes a variety of alloys and surface treatments, such as 1050, 3003, 5052, 6061, and 8011 aluminum coils. We offer surface options including mill finish, anodized, color-coated, mirror, embossed, and film-coated finishes to meet diverse requirements for weather resistance, aesthetics, and processability.

We supply aluminum coils in thicknesses from 0.2 mm to 6.0 mm and widths up to 2680 mm. Custom services such as slitting, film coating, protective film application, and specialized packaging are available to suit different project and equipment needs.

To ensure product quality, we utilize advanced eddy current testing, laser thickness measurement, and online coating inspection systems. SPC data is fully collected and analyzed to achieve process control and traceable quality for every coil.

Certified with ISO 9001, RoHS, REACH, and more, we not only ensure reliable large-scale supply but also offer flexible customization and fast-response after-sales support tailored to your needs. Contact us today for a professional quote and technical support!

What alloy series of aluminum coil can Mastar offer?

1000 series pure aluminum coil

- Alloys: 1050 | 1060 | 1070 | 1100

- Dimensions: thickness 0.2–6.0mm, width ≤ 2680mm, tolerance up to ±0.02mm

- Temper: O, H12, H14, H16, H18

The 1000 series aluminum coil is an industrial pure aluminum product, with an aluminum content typically above 99.5%. It offers excellent conductivity, thermal conductivity, and corrosion resistance. It is suitable for applications that require high processability and conductivity, such as electrical busbars, aluminum-plastic composite panels, lamp reflectors, heat exchangers, and packaging materials.

We support customized services such as uncoiling, slitting, film coating, and length cutting to meet various application requirements.

- 1050 aluminum coil

- With high purity, excellent conductivity and thermal conductivity, easy to process, and cost-effective.

- 1060 aluminum coil

- Similar to 1050, with good welding performance, excellent ductility, and suitable for deep processing.

- 1100 aluminum coil

- Slightly higher strength than 1050/1060, excellent corrosion resistance, and good surface treatment properties.

3000 series aluminum coil

- Alloys: 3003 | 3004 | 3105

- Dimensions: thickness 0.2–6.0mm, width ≤ 2680mm, tolerance up to ±0.02mm

- Temper: O, H14, H16, H18, H24, H26

The 3000 series aluminum coil uses manganese as the primary alloying element, offering good corrosion resistance and excellent formability. Its strength is higher than that of the 1000 series, making it commonly used in areas such as architectural decoration, roofing materials, exterior wall panels, shutters, kitchenware, and insulation covering materials. It is suitable for applications that require certain strength along with good processability.

- 3003 aluminum coil

- Good rust resistance and formability, suitable for deep drawing and welding.

- 3004 aluminum coil

- Higher strength than 3003, with good corrosion resistance and coating properties.

- 3105 aluminum coil

- Good weldability, strong corrosion resistance, and suitable for anodizing.

4000 series aluminum coil

- Alloys: 4032 | 4045 | 4343 | 4047

- Dimensions: thickness 0.2–4.0mm, width ≤ 1600mm, tolerance up to ±0.02mm

- Temper: O, H14, H16, H18, T6

The 4000 series aluminum coil mainly adds silicon (Silicon), with a silicon content typically ranging from 4.5% to 13%. It offers good heat resistance, wear resistance, and excellent weldability. This series of aluminum coil maintains strong mechanical properties in high-temperature environments and is widely used in fields that require high thermal performance, such as automotive engine components, radiator materials, and heat exchanger composite panels.

Customized services such as film coating, laminating, slitting, and length cutting are available to accommodate various brazing and industrial applications.

- 4032 aluminum coil

- High silicon content, strong wear resistance, low coefficient of thermal expansion, heat treatable, and high strength.

- 4047 aluminum coil

- High silicon content, low coefficient of thermal expansion, good wear resistance, and resistant to porosity formation during brazing.

- 4343 aluminum coil

- Low melting point, good fluidity, excellent brazing performance, and stable properties when compounded with materials like 3003.

5000 series aluminum coil

- Alloys: 5005 | 5052 | 5754 | 5083 | 5086 | 5454 | 5456 | 5182

- Dimensions: thickness 0.3–6.0mm, width≤2680mm, tolerance up to ±0.02mm

- Temper: O, H32, H34, H36, H38

The 5000 series is a magnesium alloy aluminum coil, known for its high strength, good weldability, and excellent resistance to seawater corrosion. It is the material of choice for industries such as shipbuilding, automotive, traffic signs, fuel tanks, and pressure vessels. The 5052 aluminum coil is particularly suitable for outdoor and high-stress environments.

- 5005 aluminum coil

- Good corrosion resistance and weldability, excellent anodizing effect, good decorative properties.

- 5052 aluminum coil

- High strength, good seawater corrosion resistance, strong weldability.

- 5754 aluminum coil

- Medium strength, good corrosion resistance, good weldability, excellent formability.

- 5083 aluminum coil

- High strength, excellent seawater corrosion resistance, excellent weldability.

- 5086 aluminum coil

- High strength, excellent corrosion resistance, particularly suitable for marine environments.

- 5454 aluminum coil

- Better corrosion resistance than 5052, suitable for medium to high-temperature environments.

- 5456 aluminum coil

- High strength, good crack resistance, excellent corrosion resistance.

- 5182 aluminum coil

- Good formability, strong impact resistance, excellent weldability, strong corrosion resistance.

- 5056 aluminum coil

- High strength, good corrosion resistance, excellent weldability, suitable for marine environments.

6000 series aluminum coil

- Alloys: 6061 | 6063 | 6082 | 6005 | 6101 | 6110 | 6060 | 6182 | 6951

- Thickness: 0.5–6.0mm, Width ≤ 2680mm, Tolerance up to ±0.02mm

- Temper: T4, T5, T6

The 6000 series aluminum coil is an aluminum-magnesium-silicon alloy, offering medium to high strength, good corrosion resistance, weldability, and excellent machinability, with the ability to be heat-treated for strengthening. It is widely used in structural profiles, rail transportation, automotive parts, building components, and industrial equipment.

- 6061 aluminum coil

- Heat treatable, high strength, good corrosion resistance and weldability, highly versatile.

- 6063 aluminum coil

- Good surface quality, excellent extrusion performance, suitable for anodizing.

- 6082 aluminum coil

- High strength, strong corrosion resistance, suitable for load-bearing structures.

- 6005 aluminum coil

- Medium strength, good corrosion resistance, suitable for complex section extrusion.

- 6101 aluminum coil

- Excellent conductivity and corrosion resistance, specially used in power systems.

- 6110 aluminum coil

- High strength, good machinability and corrosion resistance.

- 6060 aluminum coil

- Well-balanced performance, suitable for structures that require both strength and appearance.

- 6182 aluminum coil

- High strength aluminum alloy, suitable for automotive structural parts and industrial applications.

- 6951 aluminum coil

- Good formability and weldability, specially used in heat exchange systems.

8000 series aluminum coil

- Alloy: 8011 | 8021 | 8079

- Thickness: 0.2–0.6mm, Width ≤ 2650mm, Tolerance up to ±0.015mm

- Temper: O, H14, H16, H18

The 8000 series aluminum coil is primarily alloyed with aluminum, iron, and silicon, offering excellent formability, sealing properties, corrosion resistance, and moderate strength. It is commonly used in industries such as packaging, home appliances, electronics, and batteries. This series of products is mainly applied in scenarios requiring high barrier properties, hygiene, and ductility, and is especially suitable for the production of aluminum foil, pharmaceutical foil, bottle caps, and lithium battery soft packs.

- 8011 aluminum coil

- Moderate strength, with excellent moisture resistance, rust resistance, and sealing properties, suitable for stamping and lamination.

- 8021 aluminum coil

- Good ductility, strong puncture resistance, excellent barrier properties, clean surface, suitable for deep processing.

- 8079 aluminum coil

- Excellent softness, good processing performance, strong corrosion resistance, high gloss, suitable for high-end packaging materials.

Mastar's specialty aluminum coils

Aluminum trim coil

Aluminum trim coil is a lightweight, corrosion-resistant aluminum product used for door and window trim, eaves, and exterior cladding in residential and commercial buildings. It is easy to bend and ideal for decorative edge finishing.

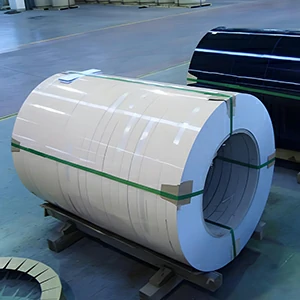

Color Coated Aluminum Coil

Color coated aluminum coil features a vibrant, uniform finish with excellent weather and corrosion resistance. It's ideal for roofing, exterior walls, ceilings, and decorative applications where both looks and durability matter.

Prepainted Aluminum Coil

Prepainted aluminum coil is spray-coated before leaving the factory, featuring consistent color and strong adhesion. It offers good processability and protective properties, making it widely used in building cladding, billboards, curtain wall systems, and more.

Anodized Aluminum Coil

Anodized aluminum coil undergoes an electrochemical treatment to form a dense oxide layer, resulting in a surface that is hard, corrosion-resistant, and less prone to fading. It is commonly used in high-end architectural decoration and electronic housings.

Embossed Aluminum Coil

Embossed aluminum coil features patterns such as orange peel or diamond textures on its surface, offering characteristics like anti-slip, decorative appeal, and aesthetic value. It is suitable for insulation material cladding, wall decoration, and appliance panels.

Brushed Aluminum Coil

Brushed aluminum coil features a fine metallic texture on its surface, providing a modern appearance and fingerprint resistance. It is commonly used in interior decoration, appliance panels, and furniture surfaces.

Mirror Finish Aluminum Coil

Mirror finish aluminum coil undergoes precise polishing to achieve a surface that is highly reflective and mirror-like. It is ideal for applications such as lighting reflectors, signage, and high-end decorative panels.

PVDF Coated Aluminum Coil

PVDF coated aluminum coil uses a fluorocarbon resin coating, offering excellent UV resistance, acid and alkali resistance, and weatherability. It is an ideal choice for outdoor building materials such as curtain walls and exterior wall panels.

PE Coated Aluminum Coil

PE coated aluminum coil uses a polyester coating, offering vibrant colors, good flexibility, and high cost performance. It is suitable for indoor ceilings, wall decorations, advertising boards, and other general environments.

Common applications of Mastar aluminum coils

Aluminum coil for gutter

Aluminum coil for gutter- Specially designed for the manufacturing of rain gutters and downspouts, it offers advantages such as lightweight, corrosion resistance, and easy formability. Coating treatments are commonly applied, making it suitable for various roof drainage systems.

Aluminum coil for roofing

Aluminum coil for roofing- Used for the formation of metal roof panels, it offers strong weather resistance and a long service life. Ideal for roofing materials in residential buildings, factories, villas, and more.

Aluminum coil for cladding

Aluminum coil for cladding- Used as a decorative and protective material for building exteriors, it offers excellent weather resistance and aesthetic appeal. Commonly used in curtain wall systems and the facades of commercial buildings.

Aluminum coil for ceiling

Aluminum coil for ceiling- Suitable for indoor ceiling systems, it is lightweight and easy to install. The surface can be sprayed or laminated to enhance the overall decorative effect.

Aluminum coil for facade

Aluminum coil for facade- Used for building facade decoration, it is corrosion-resistant and color-stable, combining modern architectural aesthetics and functionality.

Aluminum coil for rainwater system

Aluminum coil for rainwater system- Used for components in rainwater collection and drainage systems, such as gutters and downspouts, ensuring smooth roof drainage.

Aluminum coil for flashing

Aluminum coil for flashing- Used as waterproof edging material between the roof and walls, with good flexibility, customizable bending to shape, and strong leak resistance.

Aluminum coil for window trim

Aluminum coil for window trim- Used for window frame edging and decorative finishes, offering good corrosion resistance and consistent appearance, enhancing the overall architectural detailing.

Aluminum coil for insulation

Aluminum coil for insulation- Suitable for insulation cladding on pipes, tanks, and air conditioning systems, featuring lightweight, corrosion resistance, and ease of installation.

Aluminum coil for HVAC ducting

Aluminum coil for HVAC ducting- Used for the casing or lining of ventilation duct systems, ensuring durability and oxidation resistance while reducing overall weight.

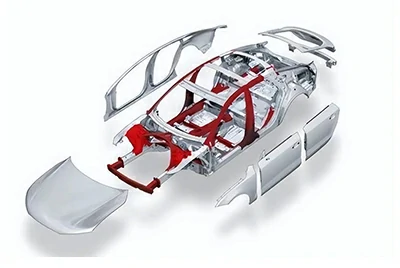

Aluminum coil for automotive body

Aluminum coil for automotive body- Used for vehicle body panels such as doors, roofs, and hoods, balancing strength and lightweight requirements.

Aluminum coil for transformer winding

Aluminum coil for transformer winding- Used for transformer coil conductors, with good conductivity and lightweight, serving as a high-quality alternative to copper wire.

Aluminum coil for LED housing

Aluminum coil for LED housing- Used for LED lamp housings, with strong heat dissipation and excellent texture, helping to enhance the overall lifespan and appearance of electronic products.

Popular size products of Mastar aluminum coil

| Product | Size | Thickness | Application |

| Aluminum trim coil 24 x 50 | 24" x 50' | 0.019" / 0.024" | Commonly used for window and door wrapping, eaves edging, and exterior trim. |

| 24x50 trim coil | 24" x 50' | 0.019" | Popular size, ideal for residential trim systems, easy to bend and install. |

| 024 aluminum trim coil | 24" x 50' | 0.024" | Thicker and stronger, suitable for high-wind or high-impact exterior areas. |

| 027 aluminum coil stock | 24" x 50' | 0.027" | Heavy-duty coil for commercial/industrial edge applications requiring rigidity. |

| 019 aluminum coil stock | 24" x 50' | 0.019" | Lightweight coil for standard window trim, gutter edges, cost-effective choice. |

| 24 aluminum coil | 24" width | Various available | Versatile width, can be cut for flashing, drip edge, fascia, and panel use. |

| 24 aluminum trim coil | 24" x 50' | 0.019" / 0.024" | Pre-painted or laminated, suitable for long-term architectural edge protection. |

| 24 trim coil | 24" x 50' | 0.019" / 0.024" | Generic search term for standard 24-inch decorative aluminum coil. |

| 24 white aluminum coil stock | 24" x 50' | 0.019" / 0.024" | White-coated aluminum, commonly used for siding, door frames, and gutters. |

| 24 x 50 aluminum painted trim coil | 24" x 50' | 0.019" / 0.024" | Pre-painted surface with vibrant colors, ideal for custom or decorative use. |

| PVC trim coil 24 x 50 | 24" x 50' | 0.019" / 0.024" | PVC-laminated surface, scratch-resistant, suitable for humid or sandy areas. |

Frequently Asked Questions About Aluminum Coil

How to calculate the price of aluminum coil?

The price of aluminum coil = (LME aluminum price × coil weight) + processing fee + shipping cost.

Since international aluminum prices fluctuate daily, we cannot provide a fixed price online.

If you would like to get a quote, please contact us.Quick Quote

How to calculate the weight of an aluminum coil?

The calculation formula for aluminum coil is:W = [(OD² - ID²) × π / 4] × w × 2.71 × 10⁻⁶

- Outer Diameter (OD): unit in mm

- Inner Diameter (ID): unit in mm

- Width (w): unit in mm

- Density of aluminum (ρ): 2.71 × 10⁻⁶ kg/mm³

What colors of aluminum coil can Mastar provide?

Mastar can provide aluminum coils in any RAL color to meet the diverse needs of customers in construction, decoration, home appliances, signage, and other fields.Commonly available colors include:

- White aluminum coil

- Black aluminum coil

- Orange aluminum coil

- Champagne aluminum coil

- Gold aluminum coil

- Blue aluminum coil

- Wood grain aluminum coil

- Marble pattern aluminum coil

- Granite pattern aluminum coil

What surface treatments are available for aluminum coil?

Common surface finishes include: mill finish, color coating (PE, PVDF), anodizing, embossing, brushing, mirror finish, and lamination (PVC or PET film).

What is the difference between PE and PVDF coatings on aluminum coil?

PE coating is cost-effective and suitable for interior or mild outdoor environments.

PVDF coating offers superior weather resistance and is ideal for long-term use in harsh conditions.

How is aluminum coil usually packaged?

Typically, coils are packed with waterproof paper + plastic film + steel straps + wooden pallets or iron frames.

Packaging orientation can be customized as eye to wall or eye to sky based on customer needs.

What are the standard inner diameters of aluminum coils?

Common inner diameters include 150 mm, 405 mm, 508 mm, and 610 mm. Selection depends on your processing equipment requirements.

Can aluminum coils be customized in color and size?

Yes, color (RAL or Pantone), width, thickness, coating type, and packaging style can all be customized according to your requirements.

Is aluminum coil easy to bend or form?

Yes, especially in soft tempers such as O, H14, and H24. These are suitable for complex bending and forming processes.

Is aluminum coil suitable for deep drawing or stamping?

Yes, especially for 1000 series and 3000 series alloys, which have excellent elongation and formability—ideal for deep drawing, covers, lighting, etc.

Can aluminum coil be laser cut or CNC machined?

Yes, most aluminum alloys can be processed using laser cutting or CNC machining under appropriate settings.

Why choose Mastar as your aluminum coil supplier?

Free Sample Available — Quality You Can See

We offer free stock samples to help you verify alloy, thickness, color, and coating before ordering, giving you full confidence in our quality.

Custom Size & Surface Options

We support customized production in terms of thickness, width, coating color, embossing pattern, and film lamination to meet personalized needs of engineering projects, fabricators, and brand clients.

Stable Quality with Test Report Provided

Every coil undergoes strict inspection before delivery, including tolerance, tensile strength, adhesion, and surface flatness. Third-party test reports (such as SGS, BV) are available upon request.

Full Alloy Range & Fast Delivery

We maintain regular stock of 1000–8000 series alloys and can quickly schedule production for color coated, anodized, embossed, or mirror finish coils. Standard sizes can be shipped within 7 days.

Bulk Orders Enjoy Tiered Discounts

For long-term partners or bulk purchases, we offer flexible pricing strategies and exclusive discounts to help you stay competitive in the market.